Greenhouse fertilizer applying machine

A fertilizer applicator and frame technology, which is applied in fertilization devices, fertilizer distributors, applications, etc., can solve the problems of high labor intensity, time-consuming and laborious, etc., and achieve the effect of reducing labor force, lightening burden, and fast fertilization operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

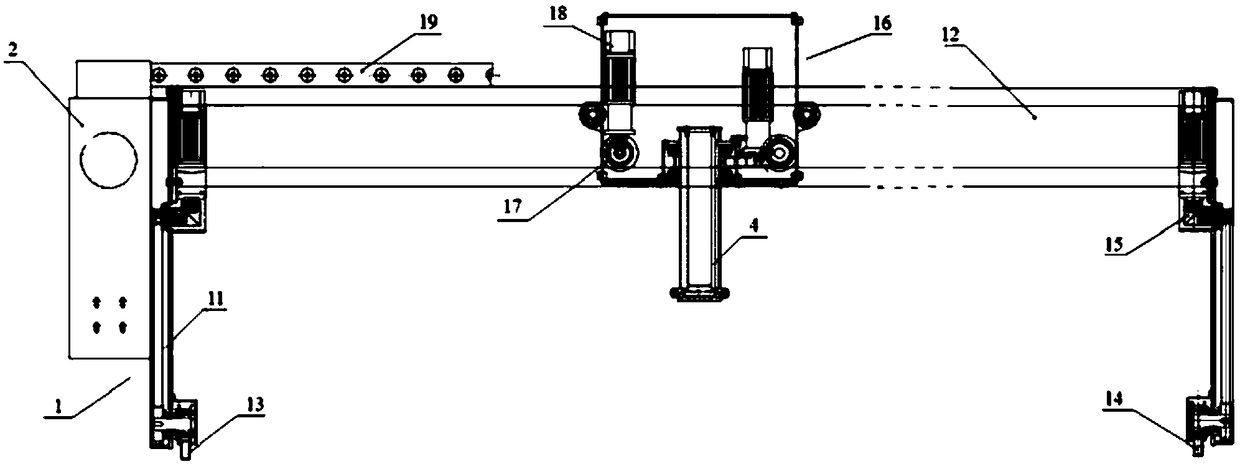

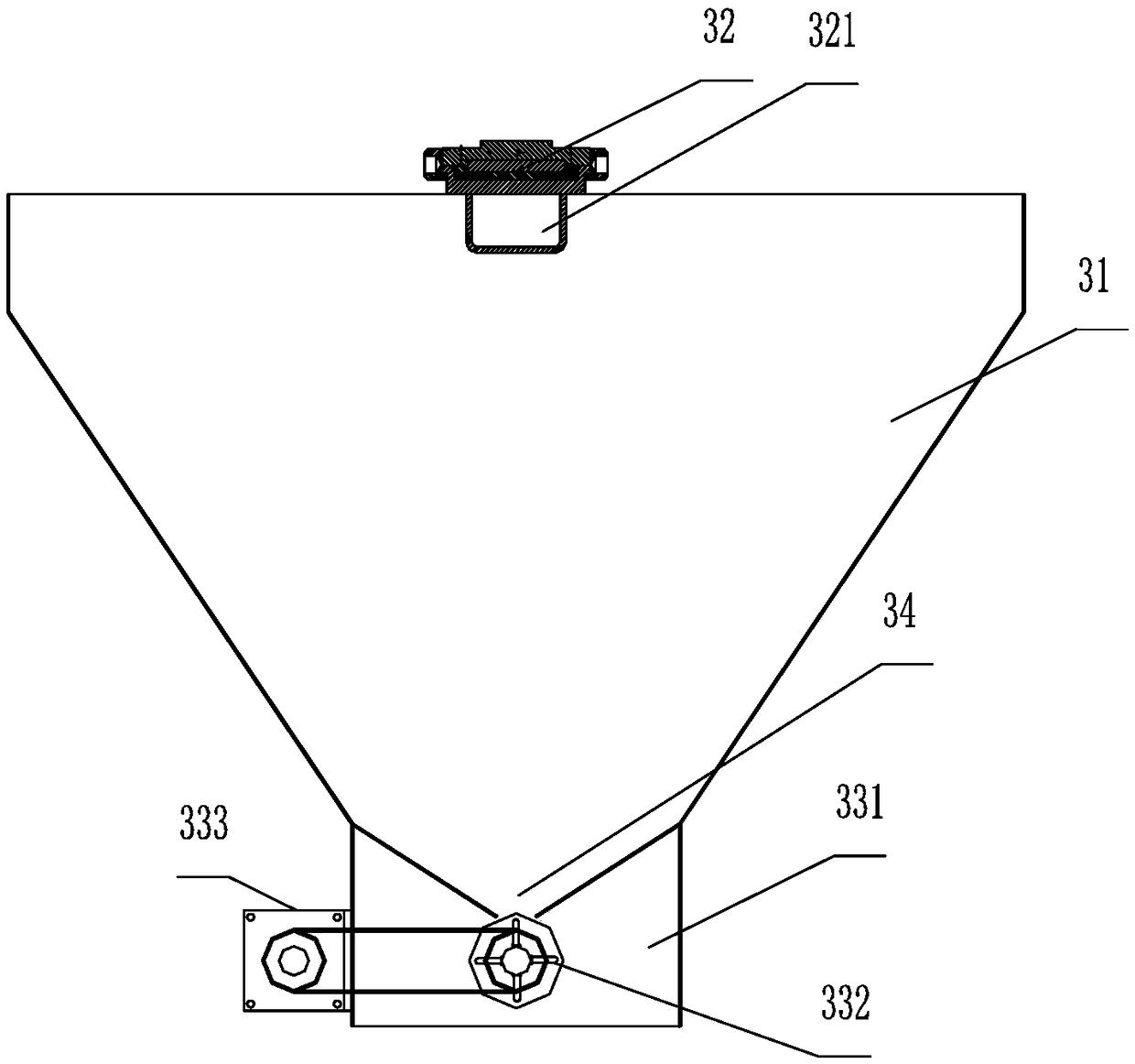

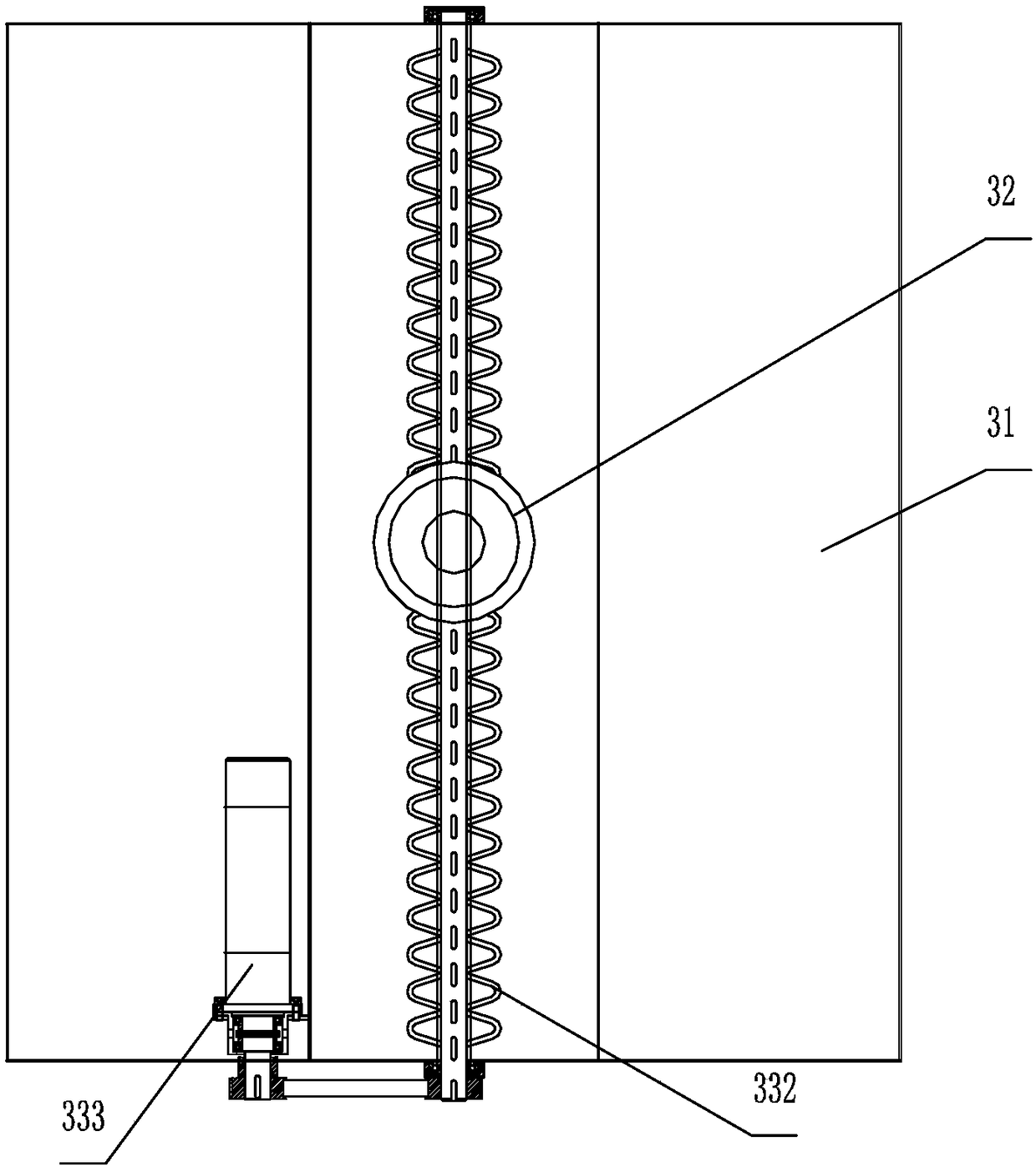

[0018] combine figure 1 , the present embodiment provides a greenhouse fertilizer applicator, comprising a first guide rail and a second guide rail arranged in parallel and a door-shaped traverse frame 1 straddling the first guide rail and the second guide rail, and the door-shaped traverse frame 1 The bottom of the support frame 11 of the frame is provided with a first moving mechanism for moving along the first and second guide rails, and the beam frame 12 of the door-shaped traversing frame is provided with a second moving mechanism for moving along the beam frame.

[0019] Specifically, the first moving mechanism includes a first moving wheel 13 that is arranged on the bottom of the support frame 11 and is compatible with the first guide rail and a second moving wheel 14 that is compatible with the second guide rail, and the support frame is also provided with A drive motor 15 that drives the first moving wheel and the second moving wheel to rotate synchronously. Wherein,...

Embodiment 2

[0024] On the basis of Embodiment 1, the connecting rod is changed to a hydraulically controlled or electrically controlled telescopic rod, which is convenient for controlling the height of the fertilizing machine head. The telescopic rod and the fertilizer applicator head can be flanged or detachably connected by clamps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com