Ditching, fertilizing, stirring, and backfilling machine

A technology of backfilling machine and ditch opener, which is applied in the direction of fertilization device, fertilizer distributor, application, etc., to achieve the effect of high fertilizer utilization rate, fast fertilization speed, saving time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

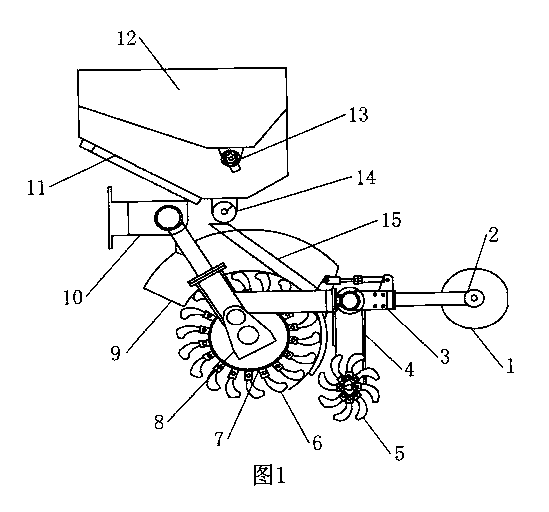

[0015] according to figure 1 As shown, an organic fertilizer box 11 is provided on the lower side of the fertilizer box 12, a fertilizer discharge device 13 is installed in the lower part of the fertilizer tank, and an organic fertilizer discharge device 14 is installed in the lower part of the organic fertilizer tank. The lower part of the fertilizer discharging device is provided with a guide groove 15 which is located behind the opener. The lower part of the organic fertilizer box is installed on the intermediate transmission box 10. The lower part of the intermediate transmission box is provided with an opener transmission box 8. The ditching wheel 7 is installed through the shaft, the ditching teeth 6 are fixed on the ditching wheel, the stirring transmission box 4 is connected to the rear of the opener transmission box, and the agitator 5 is installed at the lower part of the stirring transmission box. The rear side of the mixing transmission box is equipped with a backfi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com