Hole type topdressing machine

The technology of a top dressing device and a fertilizer box is applied in the direction of direct liquid fertilizer conveying system, agricultural gas emission reduction, etc., which can solve the problems of insufficient top dressing effect, low work efficiency, low work efficiency, etc. Avoid repeated manual adjustments and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

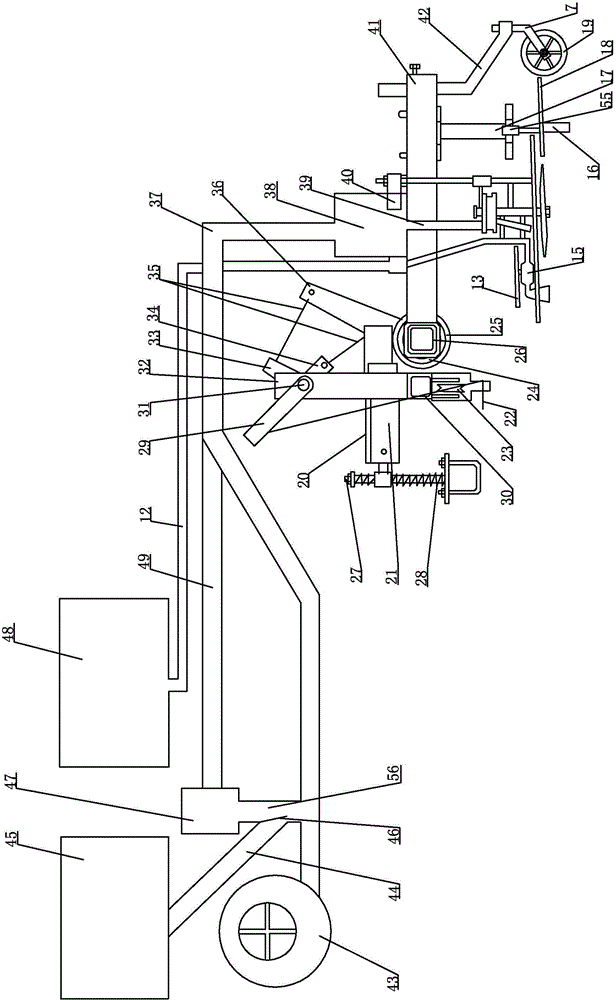

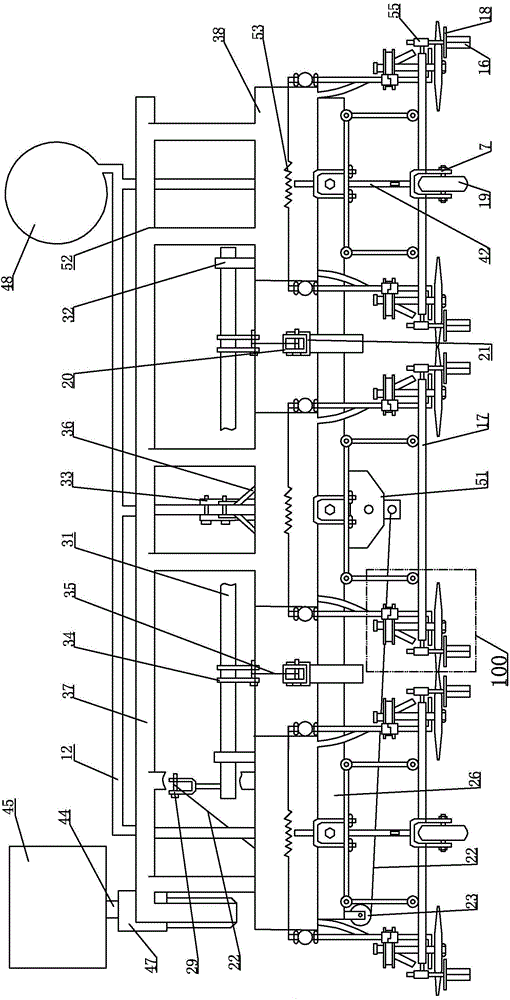

[0019] Specific implementation mode one: combine figure 1 , figure 2 and image 3 Illustrate the present embodiment, the cave type topdressing machine of the present embodiment, it comprises suspension mechanism, main frame crossbeam 26, main frame mechanism, multiple groups of ditching mechanism, topdressing mechanism and liquid mechanism, and described main frame mechanism and suspension mechanism are arranged respectively On both sides of the front and back of the main frame beam 26, the ditching mechanism is arranged on the lower end of the main frame mechanism, the topdressing mechanism is arranged on the main frame mechanism between the ditching mechanism and the main frame beam 26, and the liquid mechanism is arranged On the main frame mechanism between the topdressing mechanism and the main frame beam 26,

[0020] Described suspension mechanism comprises profile vertical support arm 27, profile arm base 21, balance spring 28, profile frame beam 30, fixed pulley 23, ...

specific Embodiment approach 2

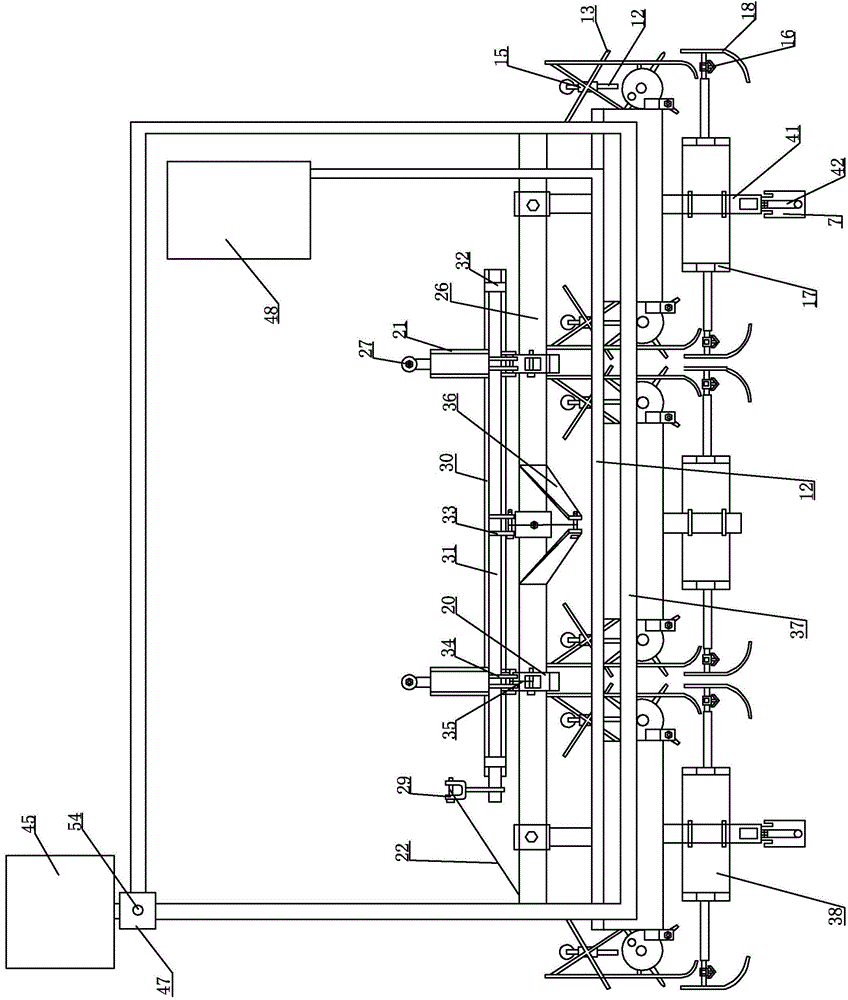

[0029] Specific implementation mode two: combination Figure 4 and Figure 5 Describe this embodiment, each group of top dressing devices 100 described in this embodiment includes a first top dressing device, and the first top dressing device includes a first fixed rotating shaft 101, a first fixed screw rod 102, a first top dressing device guide rod 103, a first top dressing device One upper fixed wheel 105, the first plucking and topdressing wheel 106, the first axle sleeve 107, the first lower fixed wheel 108 and a plurality of first connecting plates 1010, the first fixed rotating shaft 101 is horizontally arranged, and the first fixed The screw rod 102 vertically passes through the first fixed rotating shaft 101 and is fixed with the first fixed rotating shaft 101. The first top dressing guide rod 103 is horizontally fixed on the first fixed screw rod 102 through the first connecting plate 1010. The first The upper fixed wheel 105, the first plucking and topdressing whee...

specific Embodiment approach 3

[0030] Specific implementation mode three: combination Image 6 and Figure 7 Describe this embodiment, in this embodiment, each group of top dressing devices 100 includes a second top dressing device, and the second top dressing device includes a second fixed rotating shaft 201, a second fixed screw rod 202, a second top dressing device guide rod 203, The second upper fixed wheel 205, the second lower fixed wheel 208, the topdressing wheel 206, the second upper spring 207-1, the second lower spring 207-2, the second puller wheel 2011, the second topdressing shaft 2014, the second rotating shaft sleeve 2016, the second fertilizer outlet pipe 2017 and a plurality of second connecting plates 2010, the second fixed shaft 201 is arranged horizontally, the second fixed screw 202 passes through the second fixed shaft 201 vertically and is connected with the second fixed shaft 201 fixed, the guide rod 203 of the second top dressing device is horizontally fixed on the second fixing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com