Mushroom picking device

A mushroom and transmission device technology, which is applied in mushroom cultivation, horticulture, botanical equipment and methods, etc., can solve the problems of uneven growth of mushrooms, poor working environment, high labor intensity, etc., and achieve the goal of promoting the research process of intelligent mechanization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

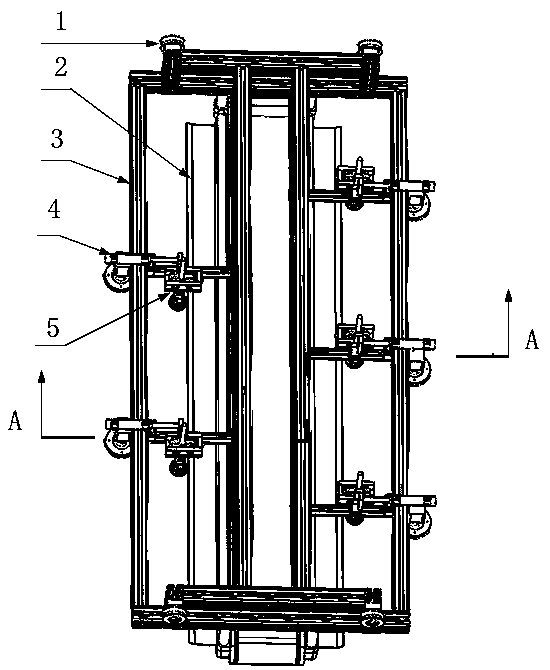

[0021] Such as figure 1 As shown, the mushroom picking device includes: frame rollers (1), mushroom transmission device (2), integral frame (3), camera device (4) and manipulator device (5), characterized in that: the camera device (4) and the manipulator device (5) are fixed on the overall frame (3) through guide plates; the mushroom transmission device (2) is connected under the overall frame (3); each side of the rack rollers (1) The two are respectively connected to the overall frame (3); the working principle is: first, the camera (4) takes pictures of the mushroom area to obtain the absolute coordinates of the mushrooms to be picked; then, the rack rollers (1) roll Realize the forward and backward movement of the overall frame (3) to drive the manipulator device (5) to reach the absolute coordinate position of the mushrooms to be picked; finally, the manipulator device (5) picks the mushrooms to be picked and transfers the picked mushrooms through the mushroom transmissi...

Embodiment 2

[0022] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows:

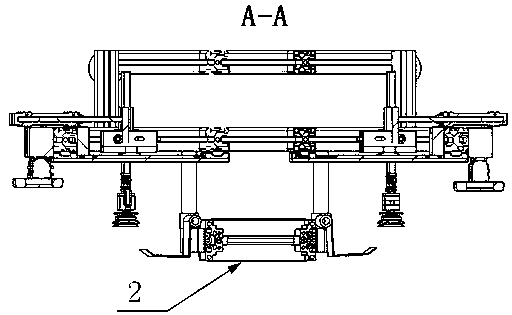

[0023] Such as figure 2 shown as figure 1 Sectional view along A-A.

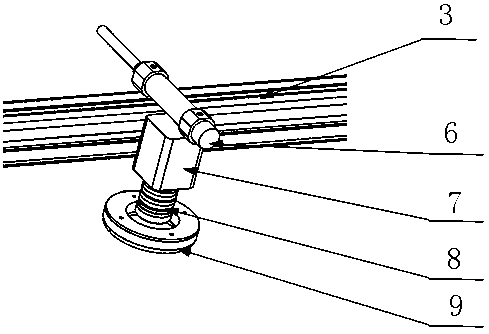

[0024] Such as image 3 Shown is a partially enlarged view of the camera device (4), which includes: a telescopic rod (6), a camera (7), a lens (8) and a light source (9), and the camera (7) is connected to The telescopic rod (6) is connected with the lens (8) to form a whole and is fixed on the overall frame (3) by the telescopic rod (6); the light source (9) is placed at the lower end of the lens (8); firstly, turn on the light source ( 9) Supplementary lighting; then, calibrate the camera (7) and the focusing lens (8), take a photo through the touch camera to get a photo of the captured area, and then transfer the photo to an industrial computer configured separately to process the world coordinate position of the target mushroom; Finally, the picking of the target mushroom is comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com