Monitoring method and device for automatic calibration of weighing base in no-load state

A no-load state, automatic calibration technology, applied in non-electric variable control, flow control, instruments, etc., can solve problems such as cumbersome steps, increased nurse workload, and inaccurate residual liquid volume alarms, to improve work efficiency and avoid problems. The effect of medical risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

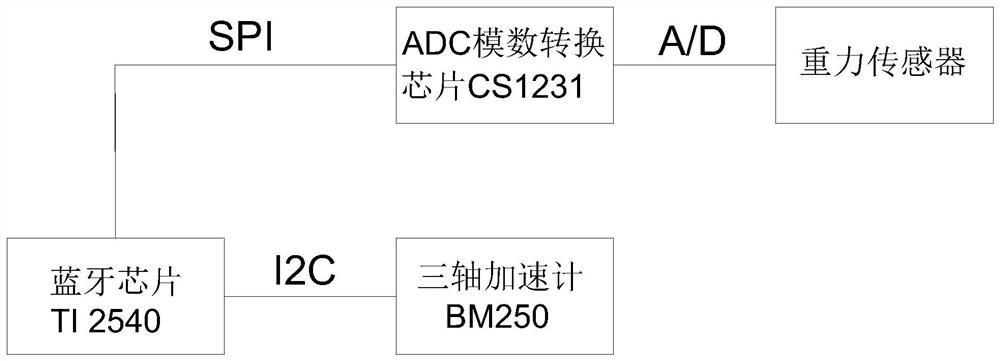

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0032] The load cell is mainly composed of four parts: sensitive element, transformation element, measuring element and auxiliary power supply. The sensitive element is used to directly feel the weight of the object to be measured and output other quantities related to its quality; The output of the component is transformed into a certain easy-to-measure signal; the measuring element is used to convert the easy-to-measure signal output by the transforming element into an electrical signal; the auxiliary power supply is used to provide an energy source for the measuring element to output the electrical signal.

[0033] During infusion, the tare weight (infusion bag, infusion bottle) data obtained by the load cell needs to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com