An automatic decomposition device for industrial waste

A technology for automatic decomposition and industrial waste, applied in the removal of solid waste, waste disinfection or sterilization methods, chemistry and other directions, can solve the problems of slow degradation, irritating temperature, affecting degradation, etc. Good crushing, easy disinfection and sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

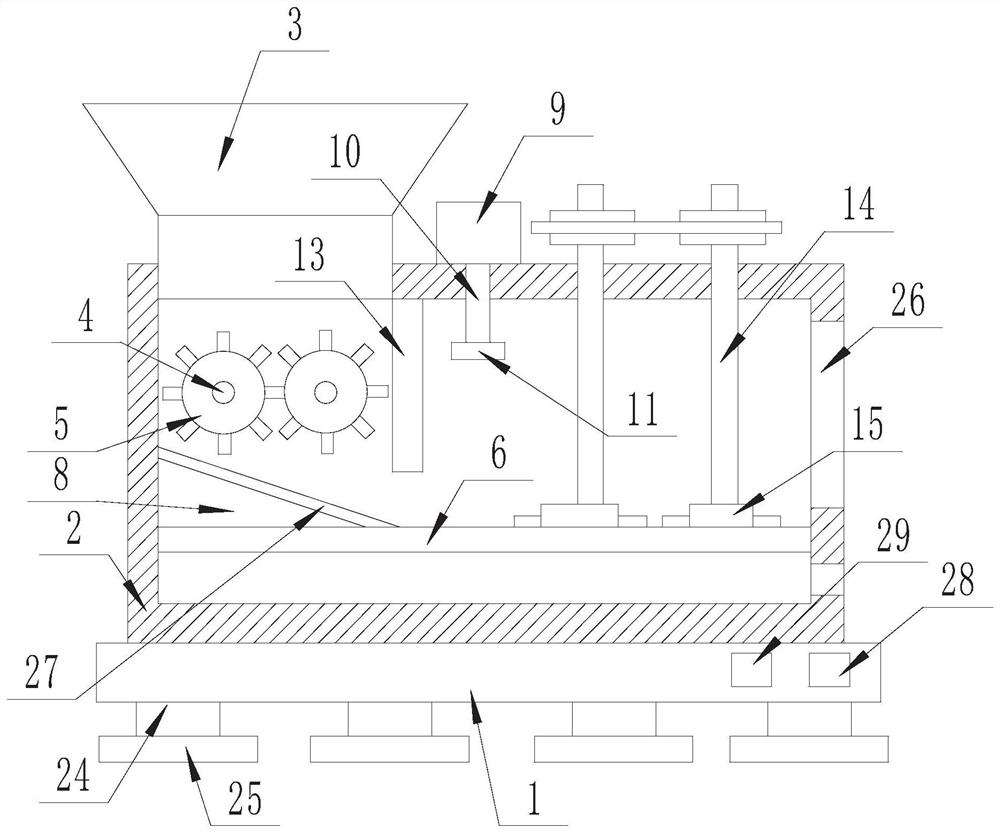

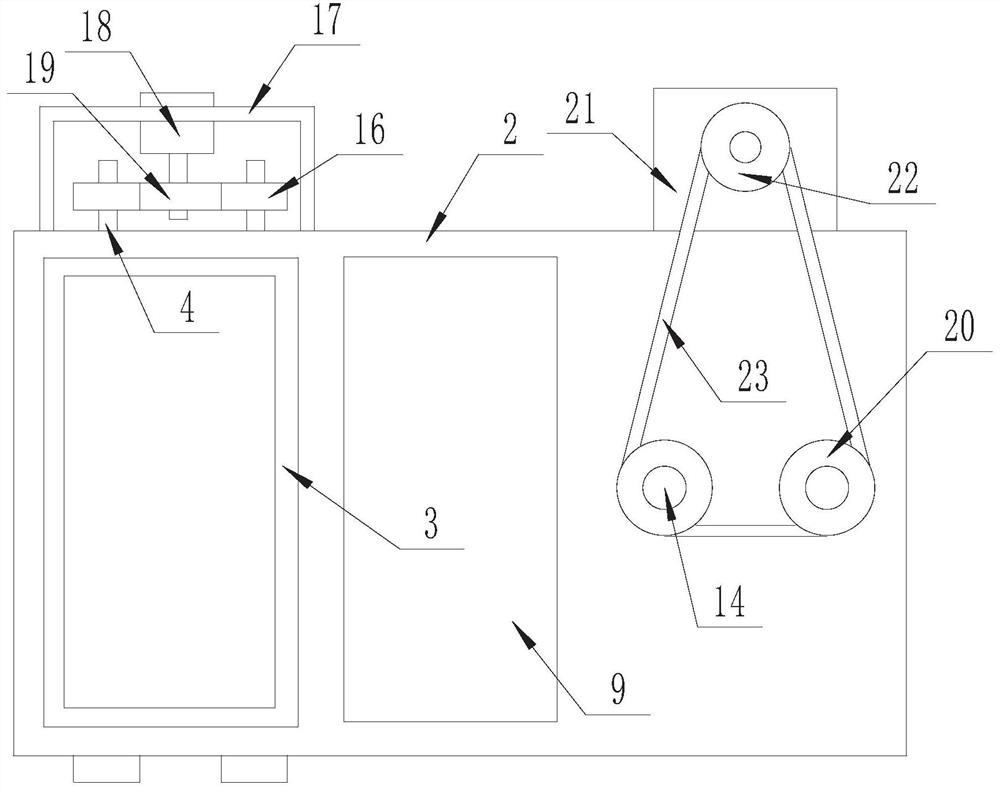

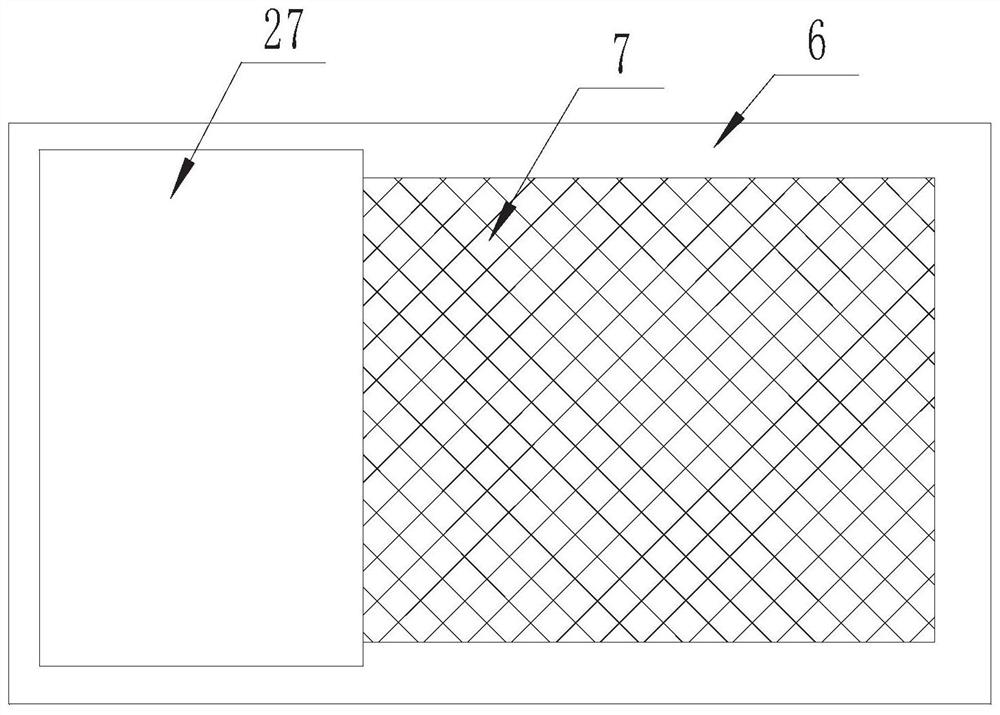

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, an automatic decomposition device for industrial waste includes a bar-shaped bearing base 1, an automatic garbage decomposition mechanism is arranged on the upper surface of the strip-shaped bearing base 1, and the automatic garbage decomposition mechanism is arranged on a strip-shaped bearing. The strip-shaped disintegration box 2 on the upper surface of the base 1, the feed inlet arranged at one end of the upper surface of the strip-shaped decomposition box 2, the wide-mouthed feed hopper 3 embedded in the feed inlet, and the strip-shaped decomposition box 2 Inside and one group of horizontally rotating round shafts 4 positioned directly below the wide-mouth feed hopper 3, a rotating crushing wheel 5 that is sleeved on each horizontally rotating round shaft 4 and matched with the strip-shaped decomposition box 2, is arranged on each A rotating mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com