Disc-type power battery module for electric vehicle

A technology of electric vehicles and power batteries, which is applied in the direction of electric vehicles, electric power units, power units, etc., can solve the problems of lower charging efficiency than fuel vehicles, inability to meet instant power replenishment, and inconsistent design of battery modules, etc., to achieve Save manpower and material costs, solve the problem of insufficient journey life, and increase the effect of mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

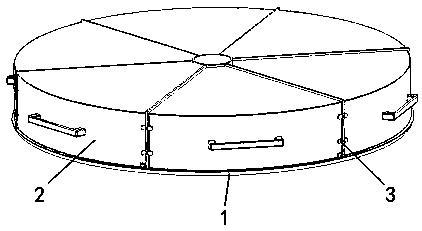

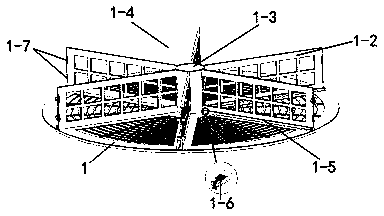

[0019] attached by figure 1 , 2 Shown: a wheel-type electric vehicle power battery module, the battery module includes a wheel-type frame 1, a single battery module 2 and a lock 3; the wheel-type frame 1 is a cylindrical disc The structure is divided into a plurality of equally divided subspaces 1-4, the single battery module 2 is arranged in the subspace 1-4, and the partition plate 1-2 of the wheel frame 1 The end is provided with a buckle 3 .

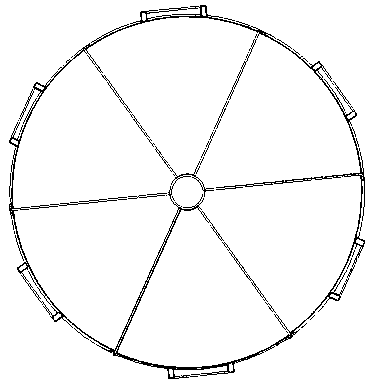

[0020] attached by image 3 , 4 As shown: the circumference of the roulette frame 1 is divided into six equal parts by a plurality of dividing plates 1-2 arranged on the base 1-1 in the radial direction, and the center of the roulette frame 1 is set Bearings 1-3 are used to fix the fixed shaft of the chassis of the electric vehicle, so that the wheel frame 1 can rotate around the fixed shaft. The wheel frame 1 adopts a high-strength steel structure, and the base 1-1 and the partition The plate 1-2 adopts a hollow design to meet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com