Trolley for mining materials

A trolley and raw material technology, which is applied in the direction of trolleys, multi-axis trolleys, trolley accessories, etc., can solve the problems of waste of manpower and material resources, poor mobility of small mineral transport vehicles, low transportation efficiency, etc., and achieve extended service life, stability and protection body safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

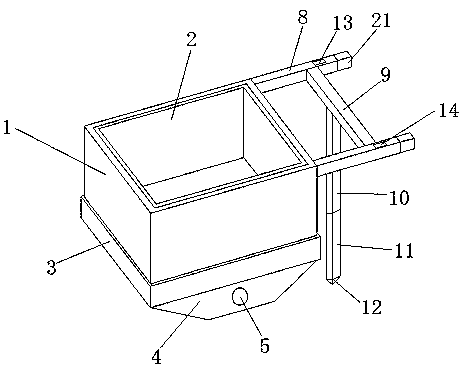

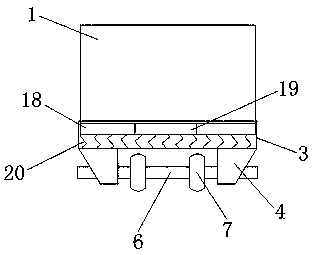

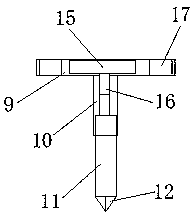

[0018] Such as Figure 1-Figure 3 As shown, a trolley for mining raw materials includes a movable car body 1. By setting the movable car body 1, the trolley can be reinforced to prevent the trolley from being broken when transporting raw materials. The inner cavity of the movable car body 1 is connected with a raw material transportation Box 2, by setting the raw material transport box 2, a small amount of mining raw materials can be put into the raw material transport box 2 for manual transportation, avoiding the danger caused by manual handling. By setting the shock-absorbing layer 3, it is possible to prevent the transportation raw material layer 2 from being tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com