Force transfer damping and anti-collision steel beam for automobile

An anti-collision steel beam and front anti-collision beam technology is applied in the directions of vehicle parts, substructure, transportation and packaging, which can solve the problems of cumbersome assembly and disassembly, and achieve the effect of protecting safety and reducing the impact force of impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will describe in detail with reference to the drawings in the embodiments of the present invention.

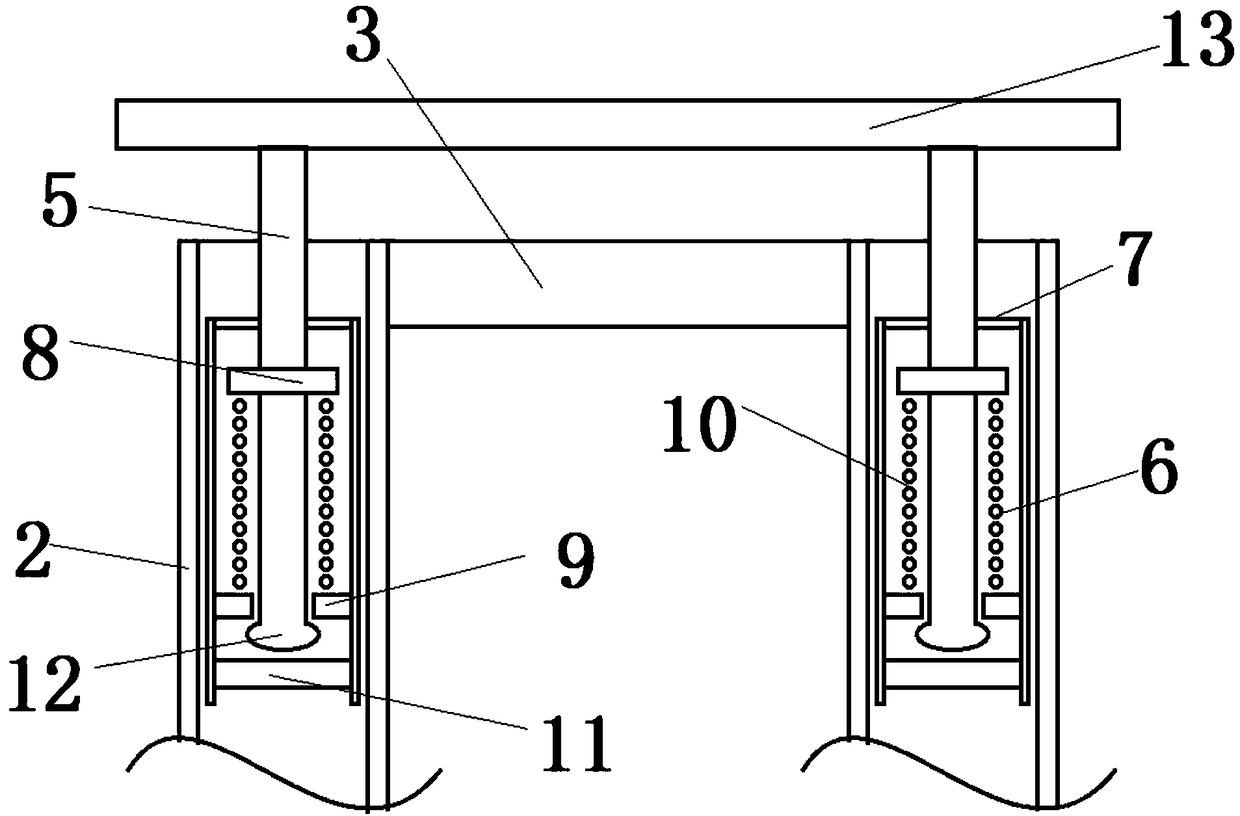

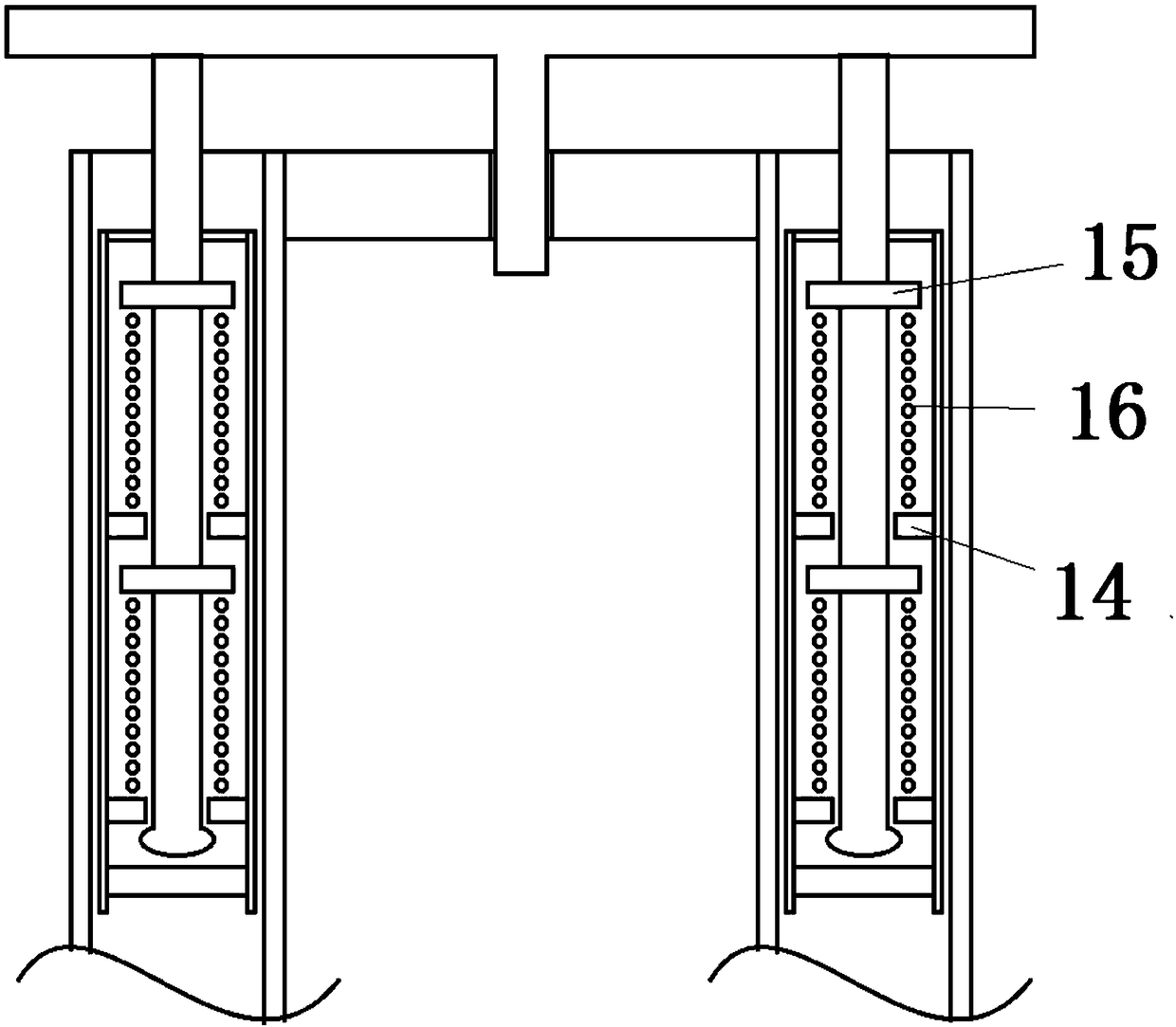

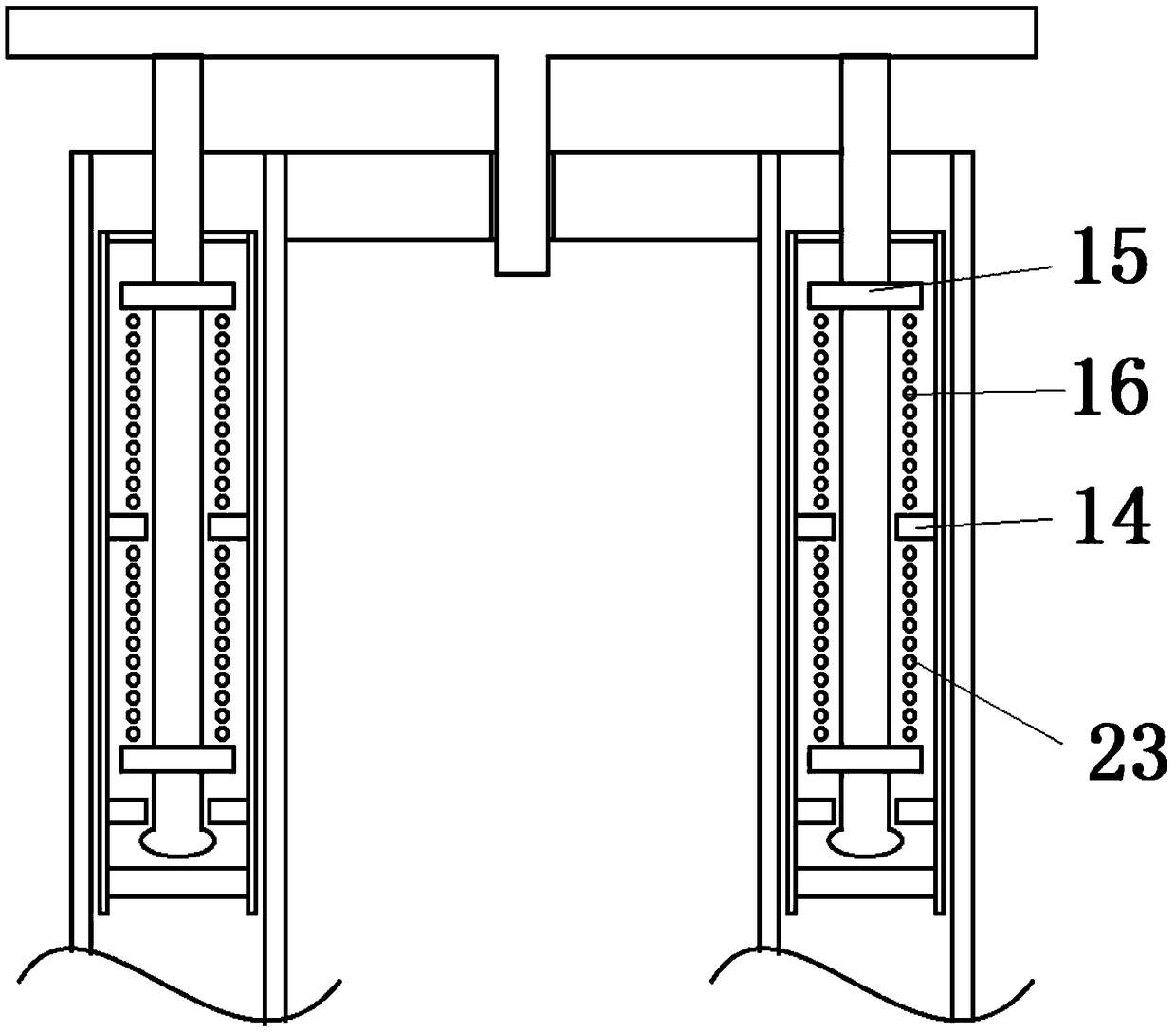

[0031] see figure 1 , a steel beam for force transfer shock absorption and anti-collision of an automobile. The automobile adopts a non-load-bearing body structure with a girder. The front beam connected to the longitudinal beam is characterized in that the automobile force transfer shock absorbing anti-collision steel beam includes: a buffer mechanism, the buffer mechanism is composed of a fixed cylinder 4, a buffer beam 5, and a first column spring 6; the fixed cylinder 4 is a pair of A tubular structure arranged side by side at intervals, and a baffle 7 is provided at any end of the fixed cylinder 4, and the center of the baffle 7 is provided with a through hole coaxial with the fixed cylinder 4; A spring seat 9, the center of the first spring seat 9 is provided with a through hole; the buffer beam 5 is coaxially nested in the fixed cylinder 4, and coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com