Corrugated board stacking device

A corrugated board stacking and stacking device technology, applied in the field of board production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

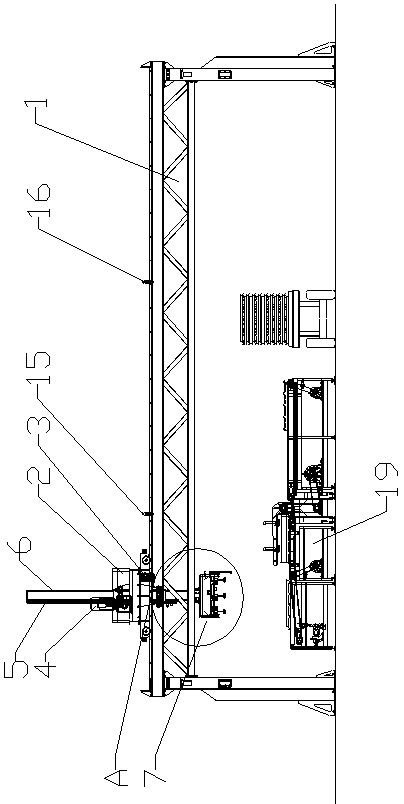

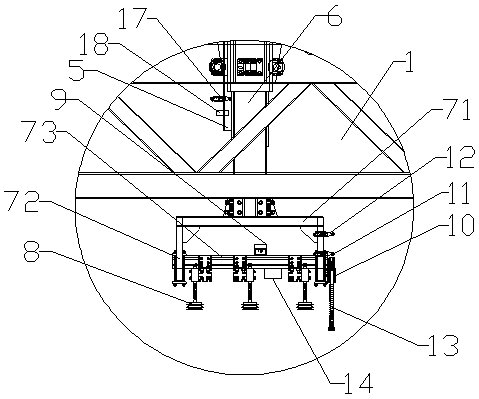

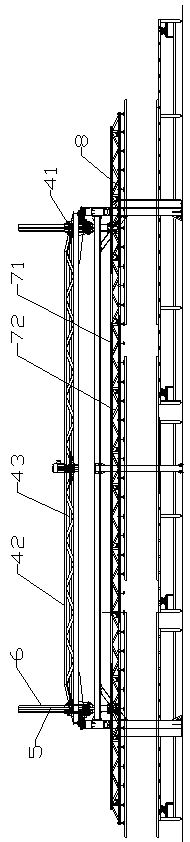

[0029] Accompanying drawing is the specific embodiment of the present invention. Such as Figures 1 to 6 As shown, this kind of corrugated board palletizing device, the whole device is controlled by the PLC control system, and also includes at least two gantry frames 1. This embodiment takes two gantry frames 1 as an example, which is also the best implementation mode. The gantry frame 1 below is the turnover machine 19, wherein:

[0030] There is a block 2 on each gantry 1, and the block 2 is driven by the traveling traverse variable speed motor 3 to move and walk on the gantry 1. The two blocks 2 are connected by a connecting frame 42, and a connecting frame 42 is fixedly installed. The lifting motor 4 and a connecting shaft 43, the lifting motor 4 drives the rotating shaft 43 to rotate, and a driving gear 41 is fixedly installed at the two ends of the rotating shaft 43 respectively, and the driving gear 41 meshes with a longitudinal rack 5, and the driving gear 41 drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com