A device for removing volatile components

A volatile and removal technology, used in evaporation, separation methods, evaporator accessories, etc., can solve the problems of reducing the heat transfer efficiency of the heating element, reducing the vacuum degree of the tank, and hindering the flow of liquid on the evaporation surface. The effect of film unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions provided by the present invention will be further described below in conjunction with specific embodiments.

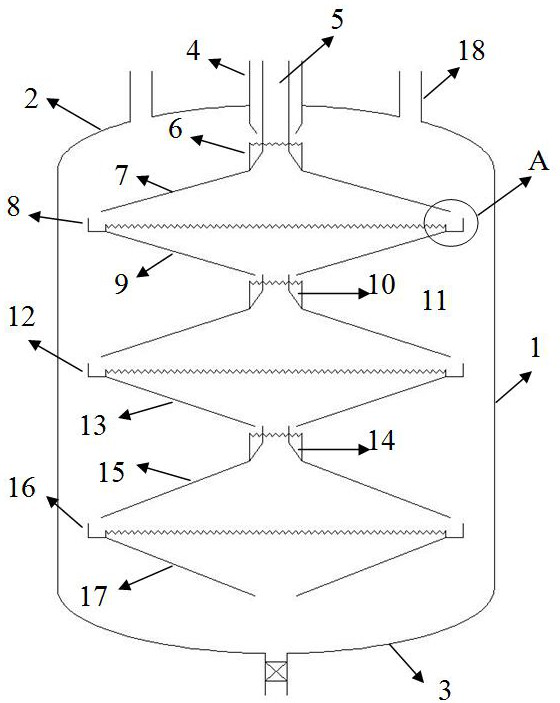

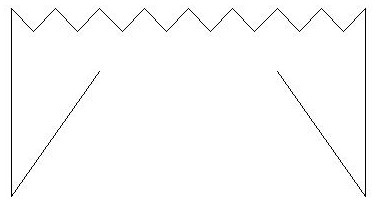

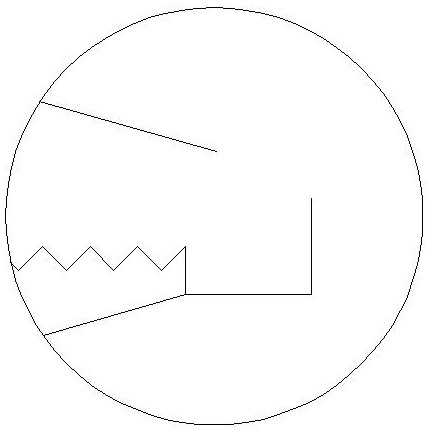

[0025] Such as Figure 1-4As shown, a device for removing volatile components includes a cylindrical tank body 1, and an upper seal head 2 and a lower seal head 3 are respectively arranged above and below the tank body 1; the center of the upper seal head 2 The position is provided with a feed pipe 4, the inner side of the feed pipe 4 is sleeved with the main outlet pipe 5, and one end of the main outlet pipe 5 extending into the tank body 1 is connected to the first evaporation unit, and the bottom of the first evaporation unit is set Second evaporation unit. The first evaporation unit includes a first upper liquid distributor 6, a first upper film distribution surface 7, a first middle liquid distributor 8 and a first lower film distribution surface 9; the first upper liquid distributor 6 includes a cone body and the distribution cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com