Formed smear device for zinc air cell anode and its production

A zinc-air battery and smear technology, which is applied to battery electrodes, electrode manufacturing, and devices for coating liquid on the surface, etc., can solve the problems of uneven smear, unstable manual operation process, etc., and overcome uneven smear , The method is simple and easy to operate, and the effect is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

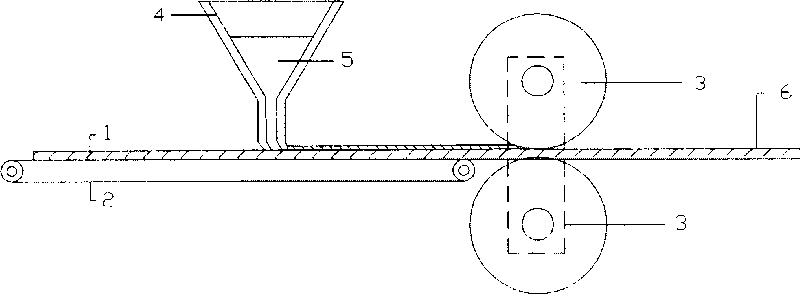

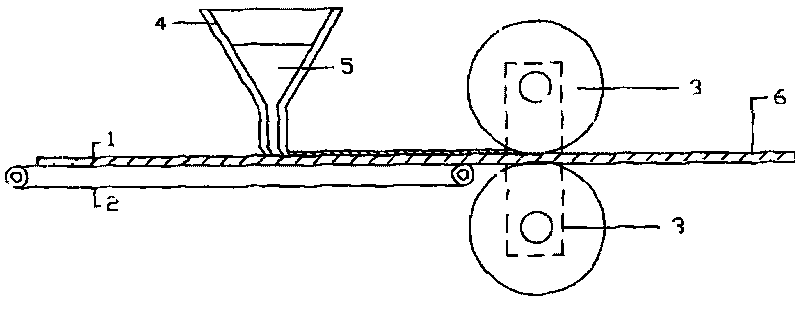

[0022] Such as figure 2 As shown, a smearing device for a positive electrode of a zinc-air battery according to the present invention includes a control device 4, a conveying device 2 and a roller press 3, the control device includes a hopper and a discharge port, and the smear is filled in the hopper. Slurry 5, the speed at which the slurry 5 flows out is controlled by the size of the discharge port. When the conveying device drives the foamed nickel 1 used for the positive electrode of the battery to move to the position where the slurry flows out of the control device 4, the slurry in the control device 4 passes through the outlet. The feed port flows out and is evenly coated on the foamed nickel. The conveying device 2 drives the coated foamed nickel to continue to move, and it is formed after being rolled by the two rollers of the roller press 3. The thickness of the positive electrode of the battery is determined by the distance between the two rollers. adjust.

Embodiment 2

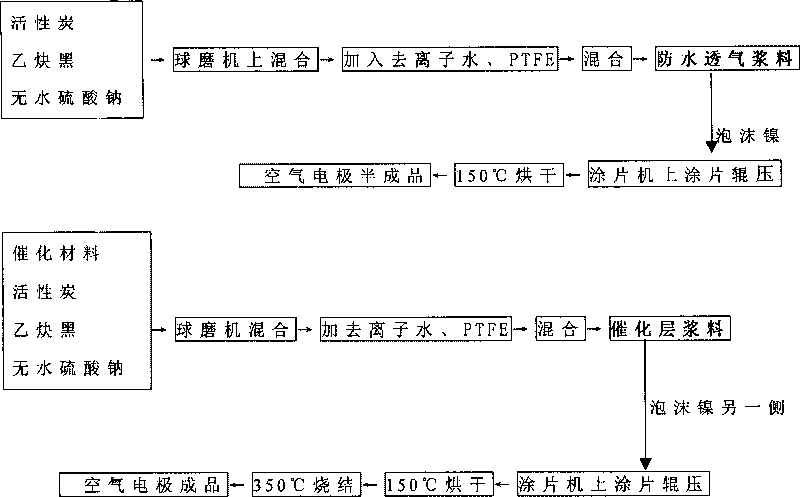

[0024] 1. Preparation of air electrode slurry:

[0025] (1) Preparation of waterproof and breathable layer slurry

[0026] Add activated carbon, acetylene black and anhydrous sodium sulfate with a mass ratio of 1:1:1 to a ball mill and mill for 30 minutes to mix evenly, add deionized water, and the mass ratio to the total solid is 5:1, and then add concentration It is 60% PTFE emulsion, wherein the quality of solids in the PTFE emulsion accounts for 25% of the total mass of solids in the slurry. After stirring evenly with a glass rod, put it into an ultrasonic generator for ultrasonication for 5 minutes to make it evenly dispersed.

[0027] (2) Preparation of catalytic layer slurry

[0028] The catalyst with a mass ratio of 3:2:2:1.5 can be MnO 2 or MnO 2 -Co, activated carbon, acetylene black, and anhydrous sodium sulfate were added to a ball mill for ball milling for 30 minutes, then deionized water was added, the quality of the deionized water was 5 times that of the tot...

Embodiment 3

[0032] 1. Preparation of air electrode slurry

[0033] (1) Preparation of waterproof and breathable layer slurry

[0034] Add activated carbon, acetylene black and anhydrous sodium sulfate with a mass ratio of 1:3:1.5 into a ball mill for 30 minutes and mix well. Add dehydrated ethanol, heat at 90°C, and stir with a magnetic stirrer, while stirring, add a PTFE emulsion with a concentration of 60%, wherein the quality of the solid in the PTFE emulsion accounts for 45% of the total solid mass in the slurry, continue to add ethanol, use Stir on a magnetic stirrer for 15 minutes.

[0035] (2) Preparation of catalytic layer slurry

[0036] A catalyst with a mass ratio of 2:3:1:1, the catalyst is self-made LiMn 1.5 CoO.50 4 , activated carbon, acetylene black, anhydrous sodium sulfate, milled in a ball mill for 30 minutes, added absolute ethanol, stirred on a magnetic stirrer, and added a PTFE emulsion with a concentration of 60% while stirring, wherein the mass of solids in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com