Cold piling box of cold piling machine

A cold stack and box body technology, applied in the field of cold stack boxes, can solve the problems of low production efficiency, poor cloth stacking state, long penetration time of cold stacking agent, etc., and achieves high utilization rate, good stacking state, and reduced penetration time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

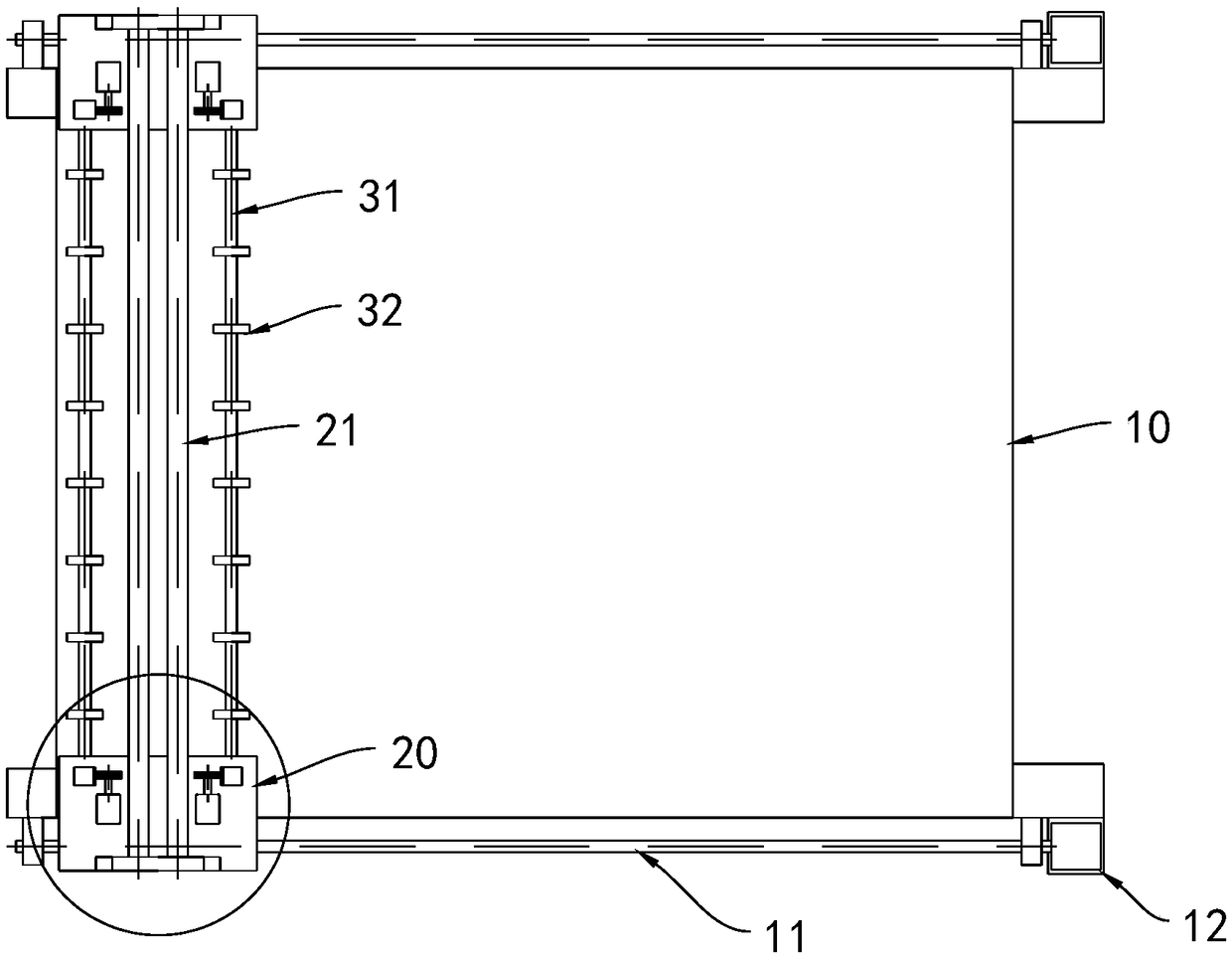

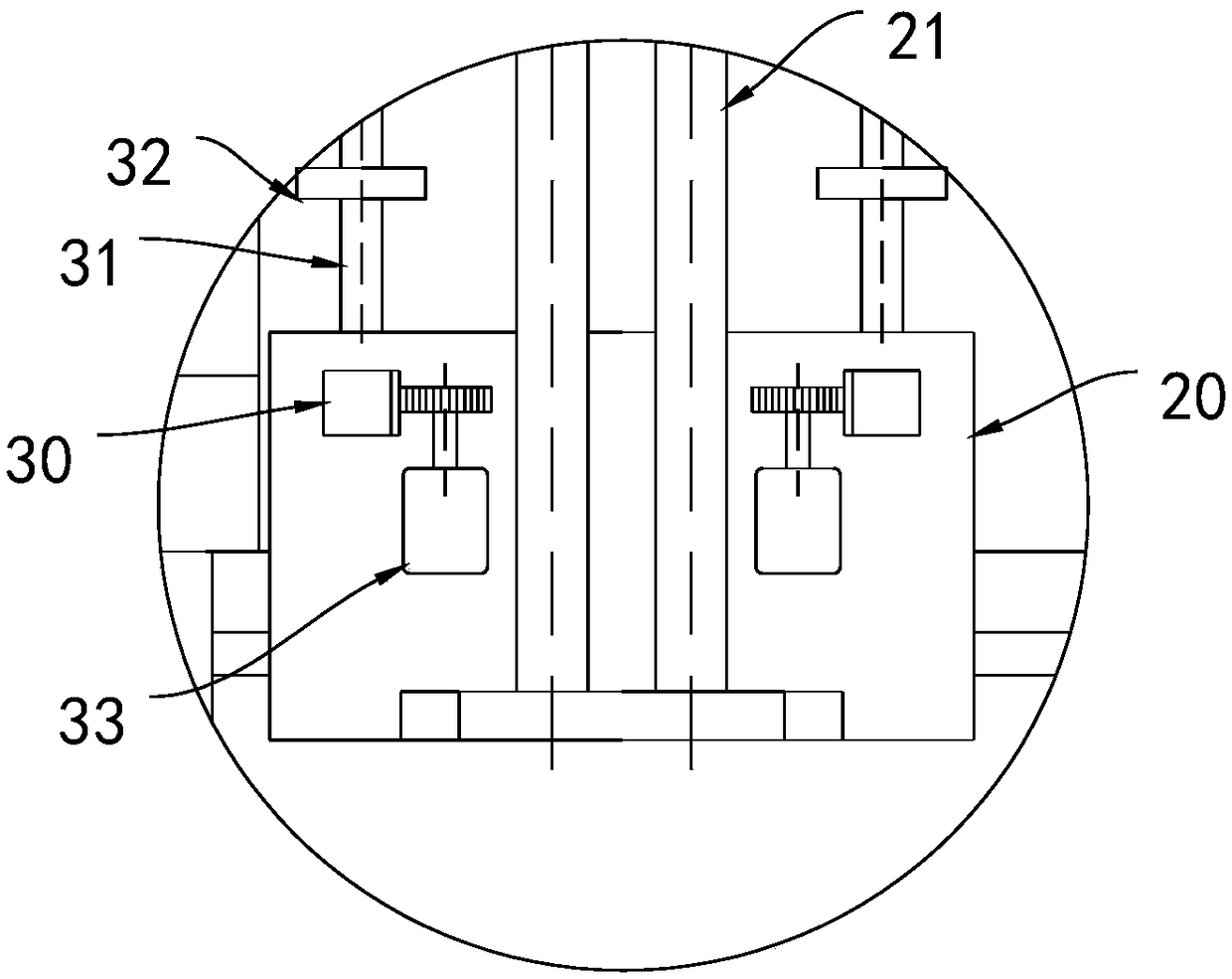

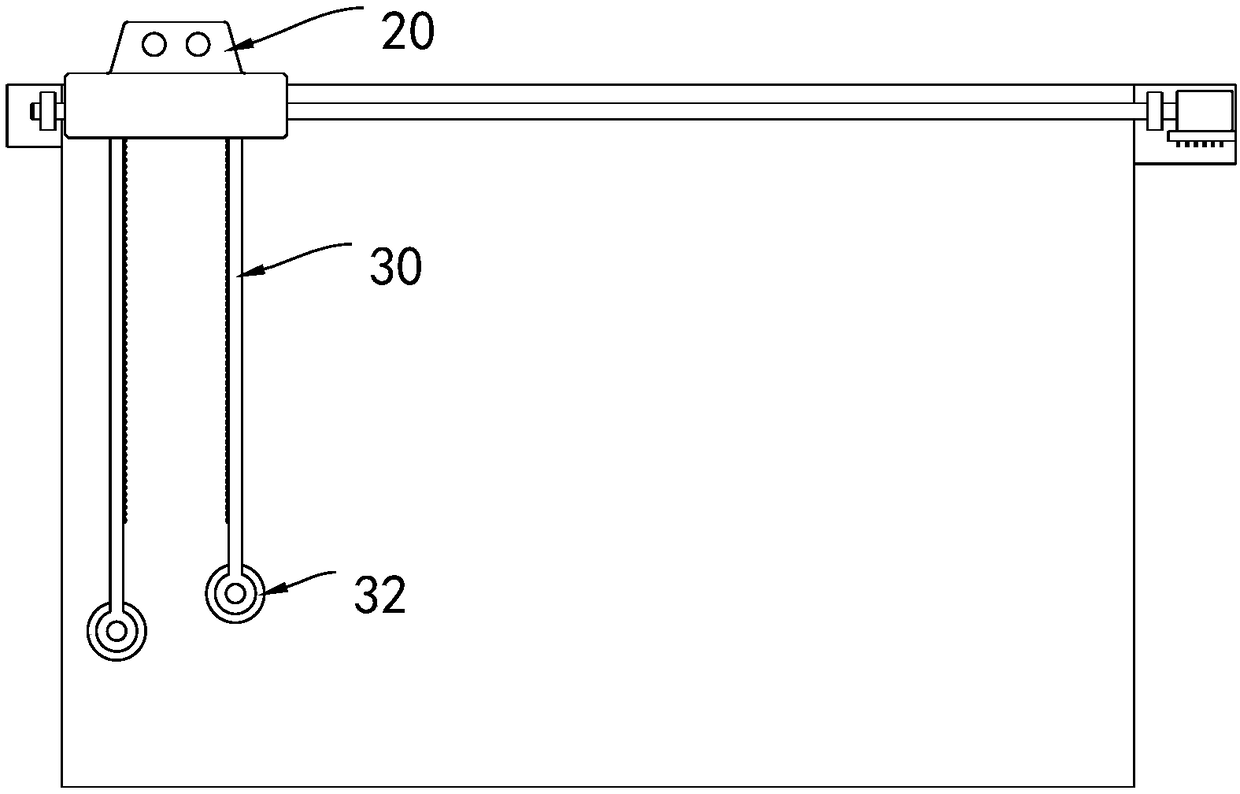

[0019] Embodiment: a kind of cold stacking box of a cold stacking machine, comprising a box body 10 with an upper opening, the upper end of the box body 10 is provided with platforms 20 which move horizontally and are arranged in pairs, and a pair of parallel nip rollers 21 are arranged between the two platforms 20 ;

[0020] It also includes two pairs of brackets 30 correspondingly arranged on the two platforms 20 , the lower end of each pair of brackets 30 is provided with a rotating shaft 31 , and the two rotating shafts 31 are located outside the nip roller 21 , and the rotating shaft 31 is provided with a guide wheel 32 .

[0021] The box body 10 is provided with a screw rod 11 matched with the platform 20 , and the screw rod 11 is connected with a first driving motor 12 .

[0022] The platform 20 is provided with a second drive motor 33, the second drive motor 33 cooperates with the bracket 30 through a rack and pinion, and the rack is a rubber rack to reduce the use of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com