In-pipe maintenance device and maintenance method thereof

A technology of maintenance device and maintenance port, applied in the direction of pipe elements, special pipes, pipes/pipe joints/pipe fittings, etc., to achieve the effect of solving fixing and adjustment, convenient use and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

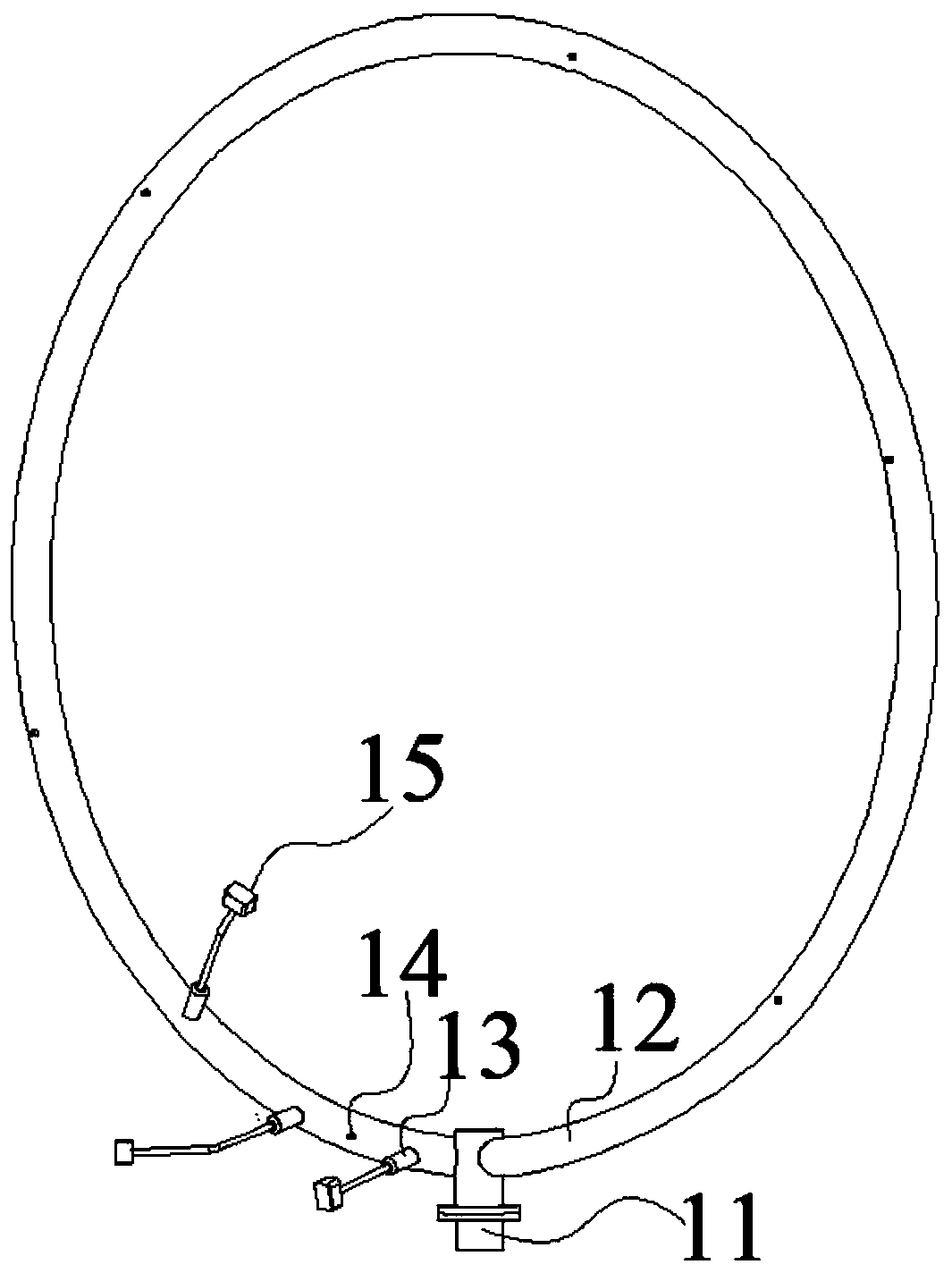

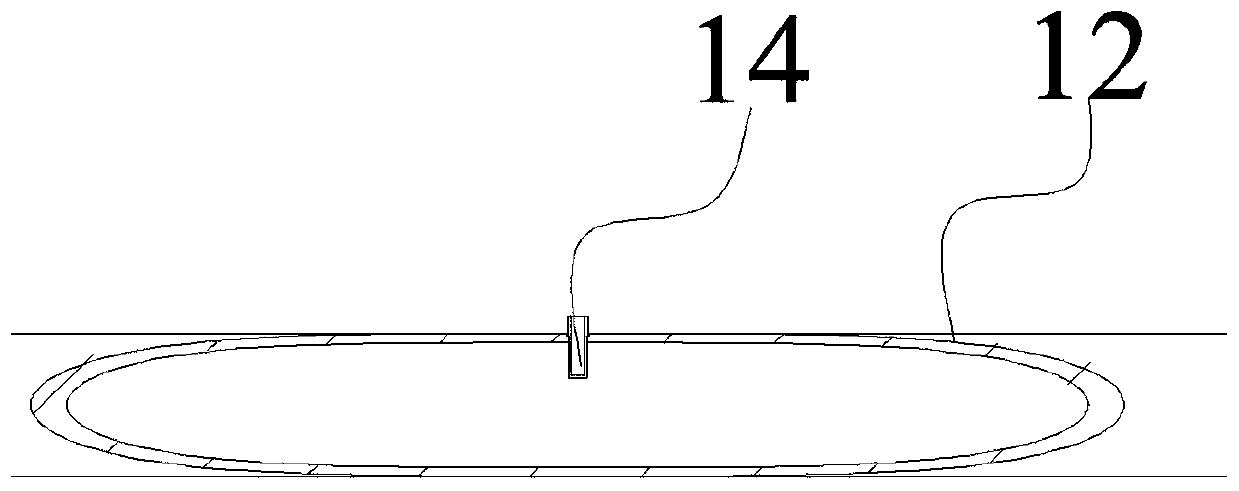

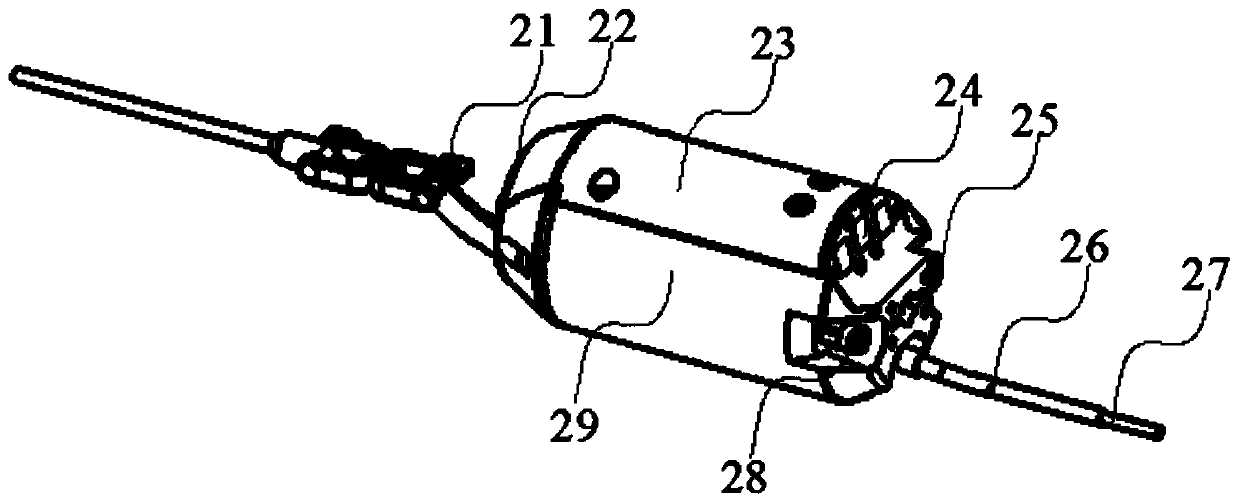

[0043] The invention discloses a fixing and adjusting mechanism of an inspection robot in a pipe, and in particular relates to a fixing and adjusting mechanism under the condition that a measuring branch pipe penetrates into an annular pipe and affects the movement of an inspection robot. Through the combination of the monitoring power assembly, the fixed regulator assembly and the universal joint, the movement of the piston rod finally realizes the fixing of the fixed frame at the nozzle of the side branch pipe, and the position adjustment of the channel frame at the nozzle of the side branch pipe is realized through the motor , to ensure that the visual cleaning nozzle can smoothly enter and exit the nozzle of the side branch pipe to complete the corresponding cleaning or video inspection work. This structure is easy to use, high in stability and high in adjustment efficiency, and can effectively solve the fixing and adjustment of the equipment under the above working conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com