A maintenance platform for adss optical cable

A technology for overhauling platforms and platforms, applied in optical fiber/cable installation, optics, light guides, etc., can solve the problems of ADSS optical cable not being able to go out, electrical corrosion at the outlet of tensile optical cable fittings, etc., to improve work efficiency, reduce weight, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

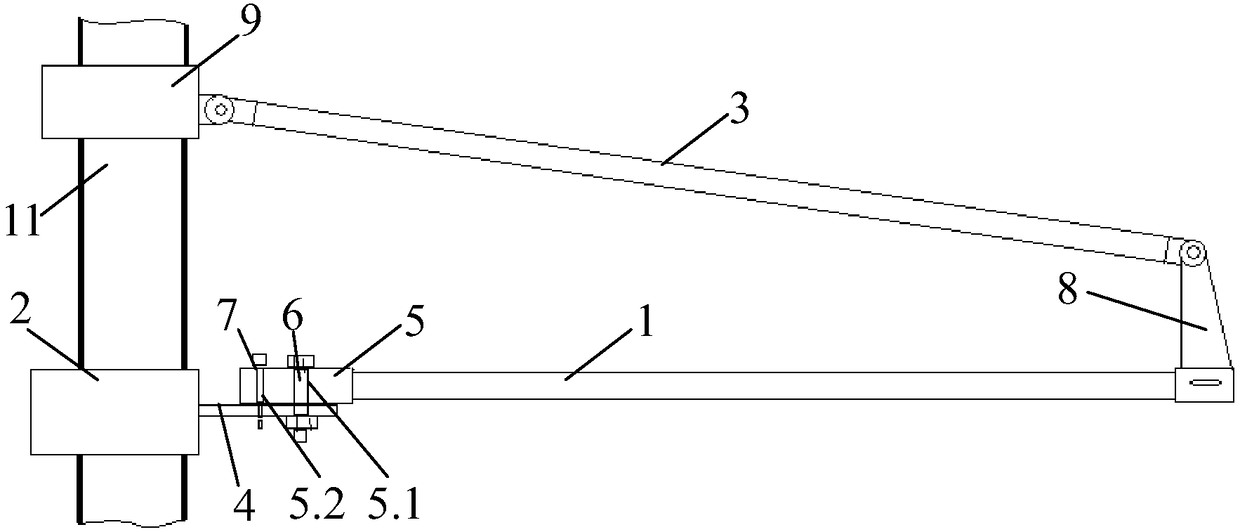

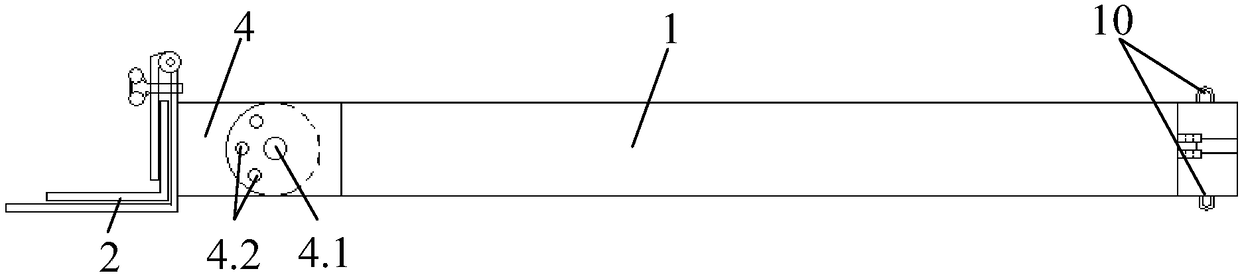

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

[0024] see figure 1 with figure 2 , the ADSS optical cable maintenance platform of the present invention comprises a platform 1, and one end of the platform 1 is provided with a platform clamp 2 that can be fixed on the iron tower, and the other end of the platform 1 is connected with a pull rod 3 through a hinge, and the pull rod 3 adopts The cable-stayed way connects the platform 1 and the iron tower 11 together. The rear end of the tie rod is fixed on the main material of the iron tower with a clamp, and the front end is connected with the front end of the platform with a high hinge, forming a stable triangular structure, and the staff can move freely within the triangle.

[0025] As shown in the figure, a rotating shaft mechanism capable of rotating the platform 1 around the clamp 2 is provided between the platform 1 and the platform clamp 2 . The rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com