Heater box

A technology for heaters and cabinets, which is applied in household heating, space heating and ventilation details, heating methods, etc. fire effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

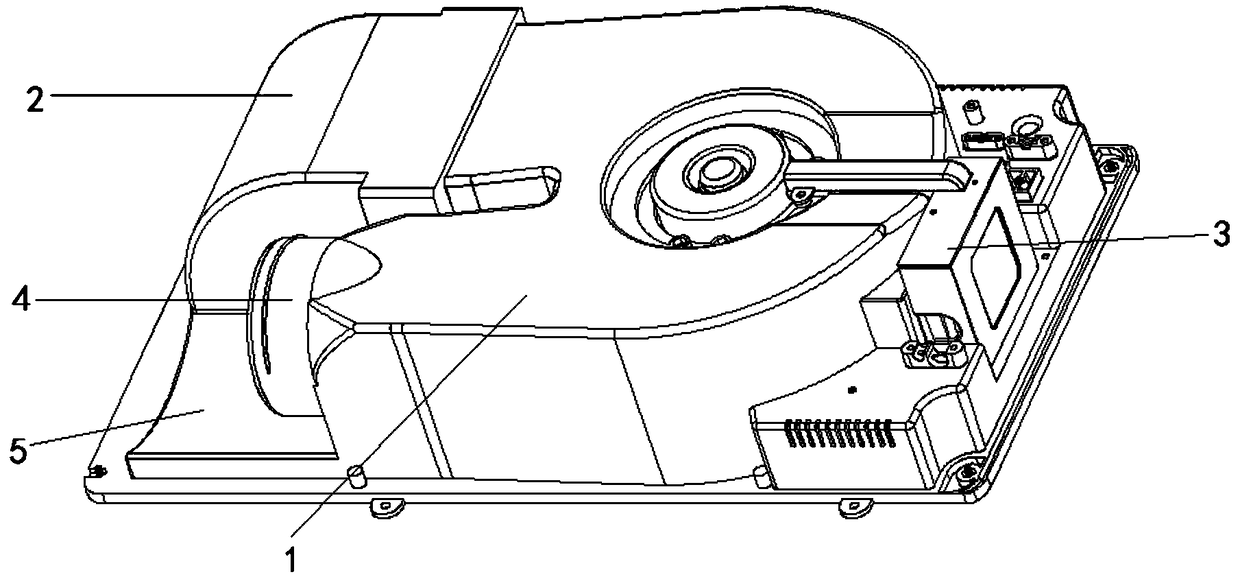

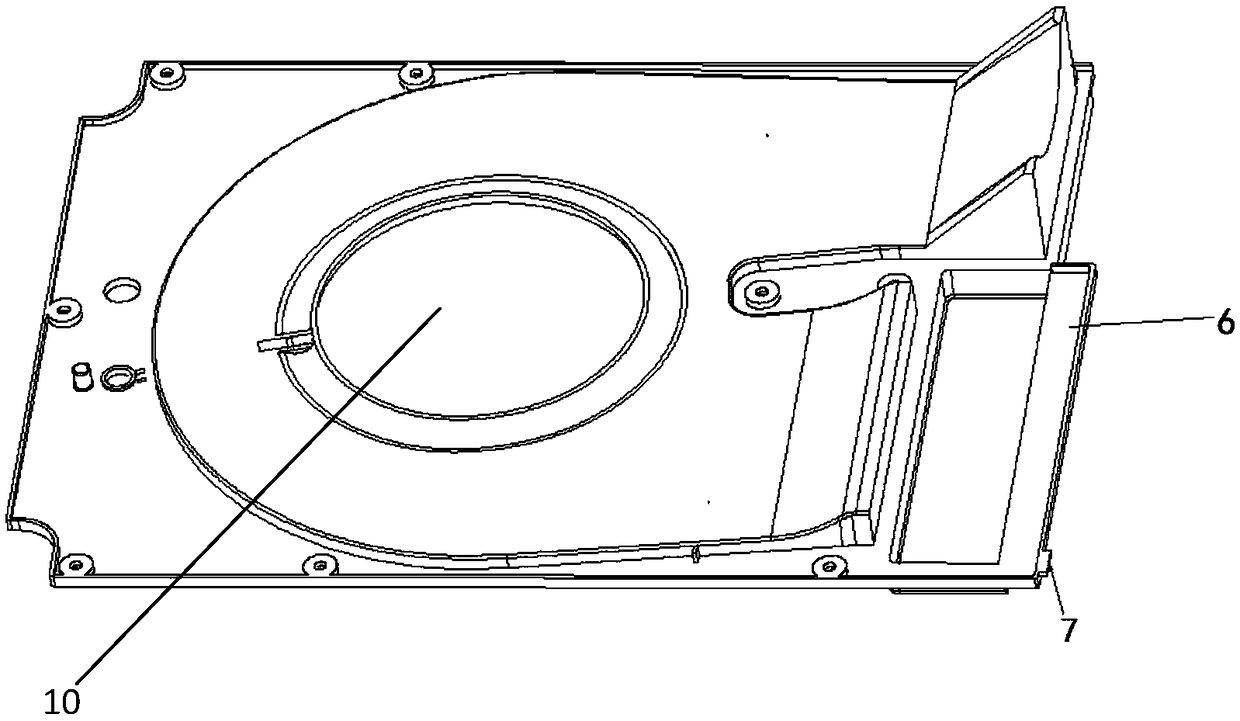

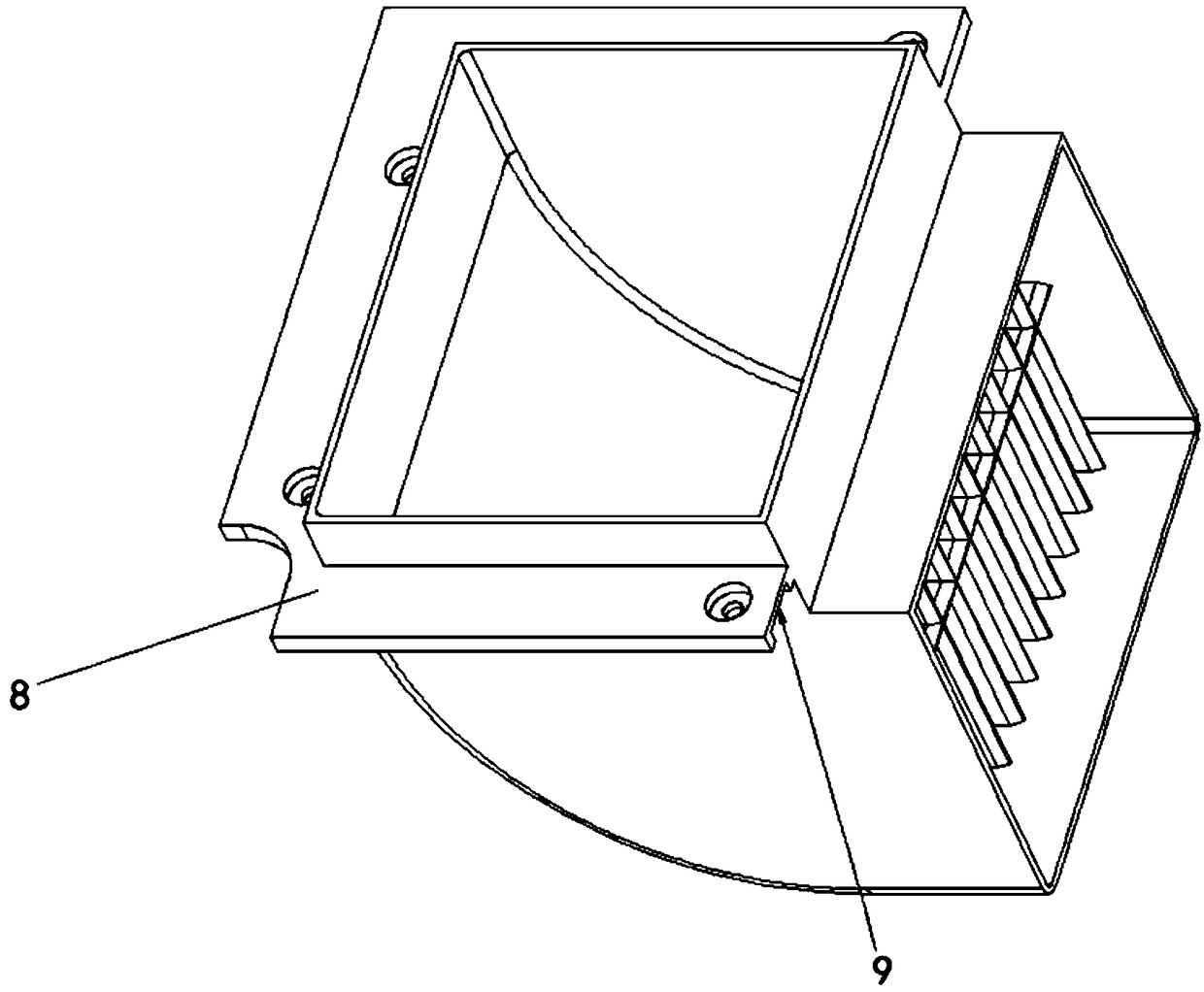

[0019] Embodiment 1: as Figure 1 to Figure 4 As shown in , a heater box includes a box body and a cover plate. There is a U-shaped groove in the middle of the box body. The U-shaped groove is covered by a cover plate to form an air duct 1. There is a One end of the air inlet duct 1 is connected to the air outlet duct 2, and the other end is a circular ventilation outlet 4. There is an arc-shaped surface 5 on the main body surface of the box below the ventilation outlet 4. The inner side of the air outlet duct 2 is right-angled, and the outer side It is arc-shaped, the rear end communicates with the air duct 1, and the front end extends outwards with a fixed surface 8, which is fixed to the front of the main body of the box, and the back of the fixed surface 8 is provided with a groove 9; Junction box 3; one end of the cover plate has a protruding clamping surface 6, and the side wall of the clamping surface 6 has clamping feet 7 extending outward, the clamping surface 6 is ag...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap