Overturning test device

A testing device and flip-type technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum, can solve the problems of high labor intensity of workers, large water heater volume, and inconvenient movement, so as to reduce manual participation in the process and increase the degree of automation High, to avoid the effect of reciprocating handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

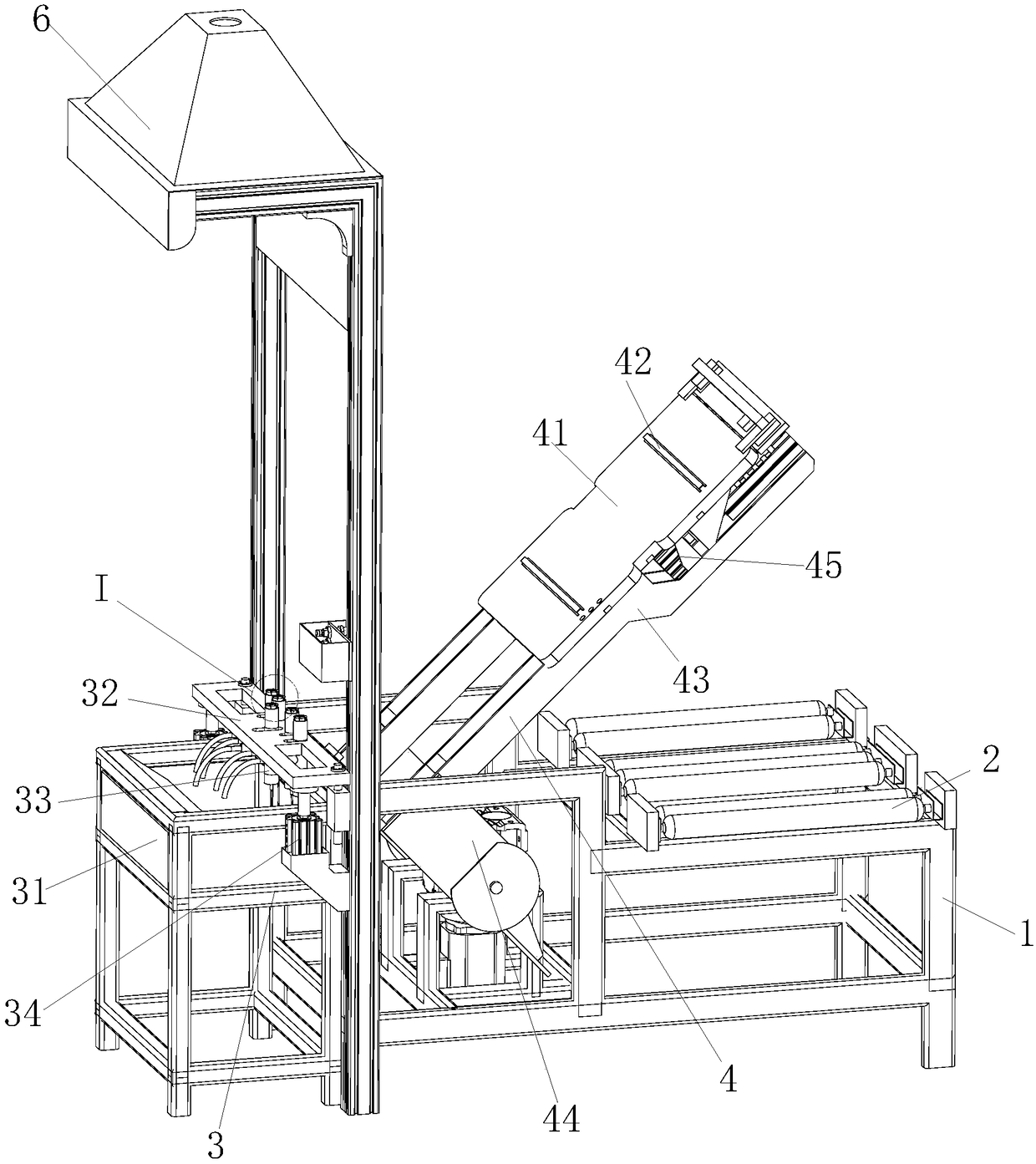

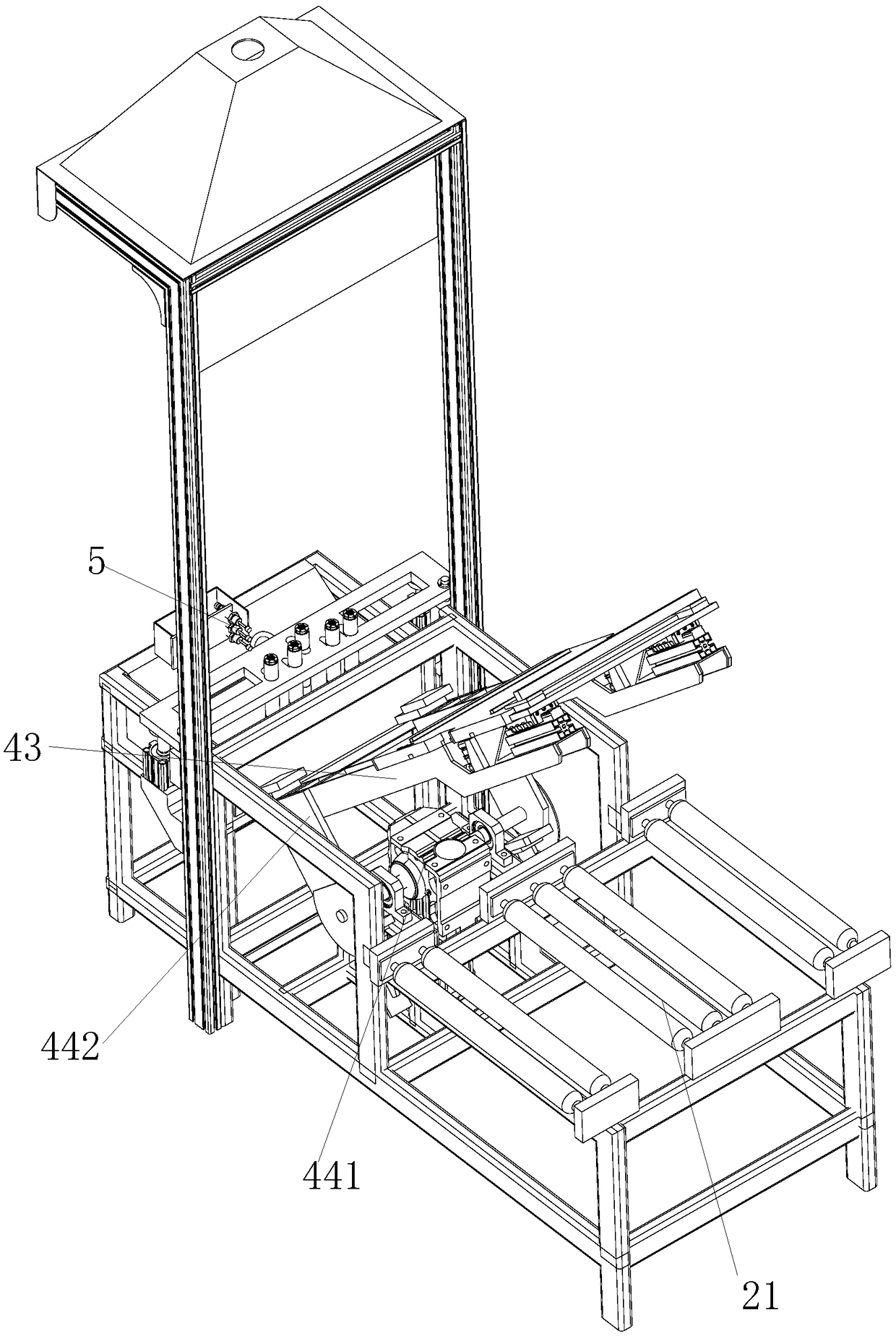

[0023] Such as Figure 1 to Figure 6 As shown, a flip-type test device includes a frame 1, one side of the frame 1 along its length direction is provided with a drum line 2, and the other side is provided with a detection device 3, and the middle part of the frame 1 is provided with There is an overturning table 4 that can fit on the drum line 2 and can be rotated to the top of the detection device 3 .

[0024] The roller line 2 includes three groups of rollers 21 arranged at intervals along the width direction of the frame 1 .

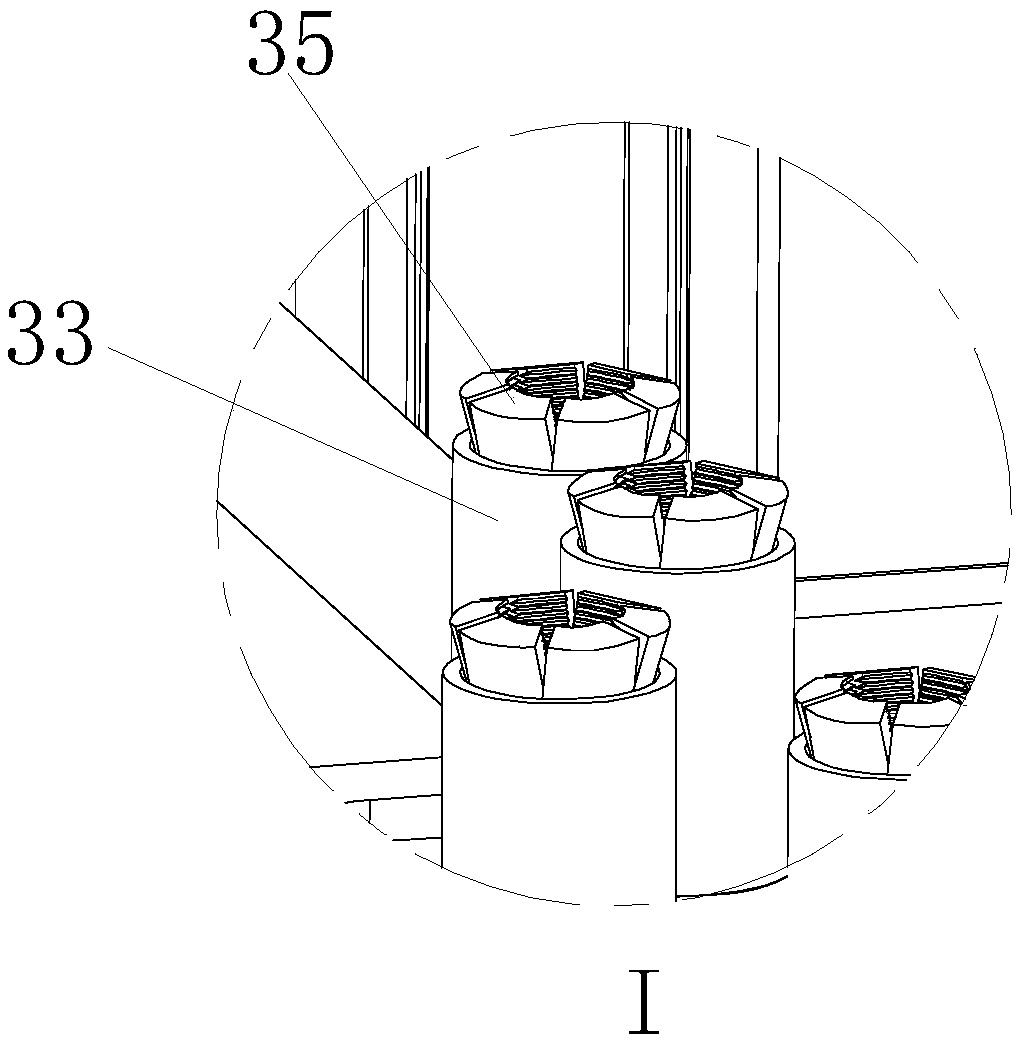

[0025] The turning platform 4 includes a loading plate 41, a positioning bar 42 fixed on the loading plate 41, two turning poles 43 slidingly connected to the bottom of the loading plate 41, and a driving mechanism 44 connected to the turning poles 43. Any on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com