Clamping device for longitudinal arc tensile sample

A technique for tensile specimens and clamping devices, which is applied in the mechanical field to achieve the effects of ensuring uniformity, ensuring stability, and convenient clamping and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

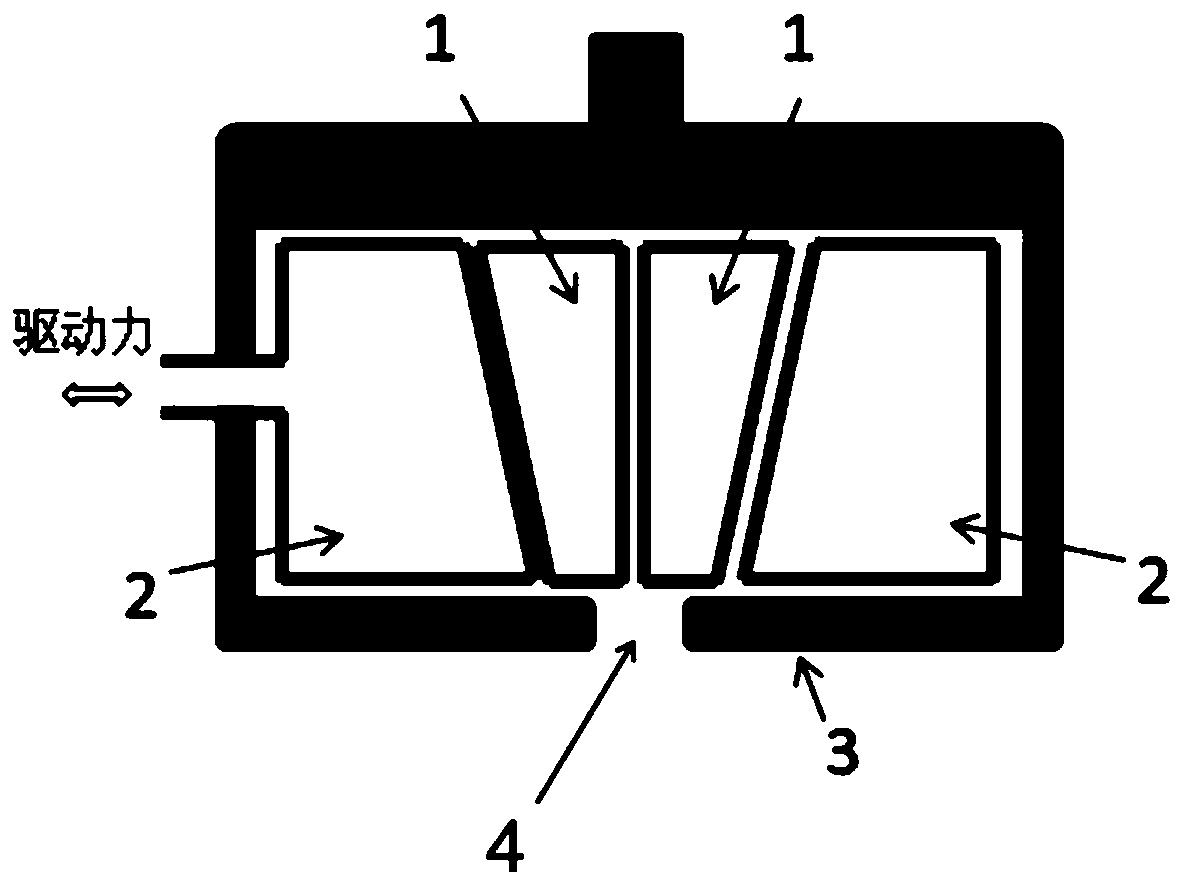

[0032] Such as figure 2 As shown, in this embodiment, the driving force of the driving mechanism is perpendicular to the clamping surface of the clamping block 1 , and only one elastic block 2 is loaded with driving force.

Embodiment 2

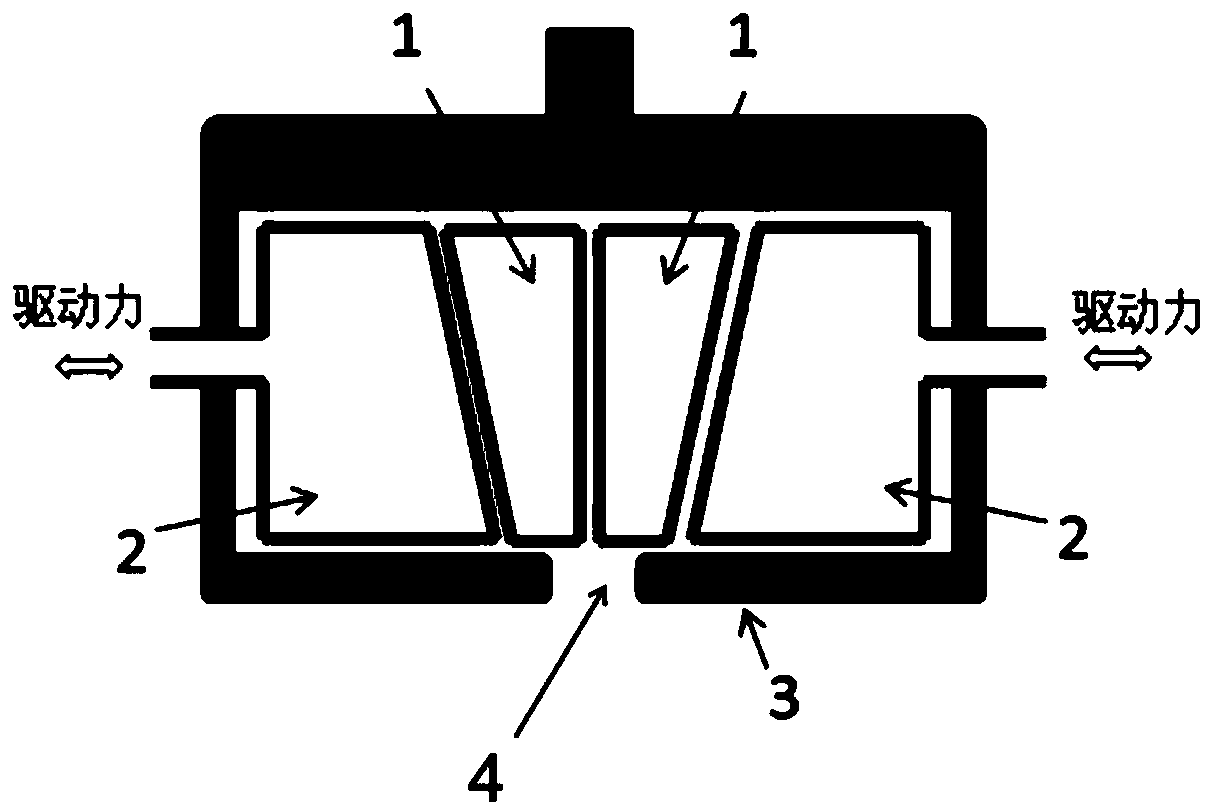

[0034] Such as image 3 As shown, in this embodiment, the driving force of the driving mechanism is perpendicular to the clamping surface of the clamping block 1 , and all the elastic blocks 2 are connected with the driving mechanism.

Embodiment 3

[0036] Such as Figure 4 As shown, in this embodiment, the outer surface of the clamping block 1 is wedge-shaped, and the elastic block 2 is provided with a wedge surface matching the outer surface of the corresponding clamping block 1; the driving force direction of the driving mechanism is not in line with the wedge face parallel. In this way, when the driving force acts on the wedge surface, a component perpendicular to the direction of the clamping surface will be generated, so as to realize the clamping function of the clamping block 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com