A Calculation and Prediction Method of Tensile Strength of Hot-rolled Wire Rod

A tensile strength and wire technology, which is applied in the field of calculation and prediction of the tensile strength of hot-rolled wire, can solve the problems of product selection, design and process preparation difficulties, and the inability to obtain data or data in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate the understanding of those skilled in the art, the present invention will be described in detail below in conjunction with specific embodiments.

[0033]

[0035]

[0040]

[0042]

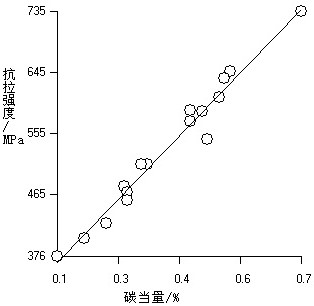

[0044] low carbon:, r=0.9849

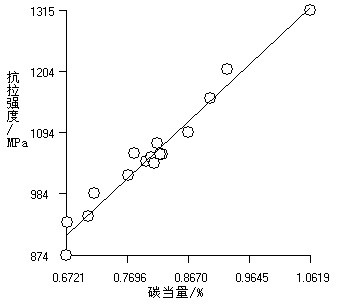

[0045] Medium and high carbon:, r=0.9855

[0048] The above is only a specific application example of the present invention, and does not constitute any limitation to the protection scope of the present invention. Where adopted

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com