Electrode management cabinet

A technology for managing cabinets and welding rods, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., which can solve the problems of wasting manpower and inaccurate records.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

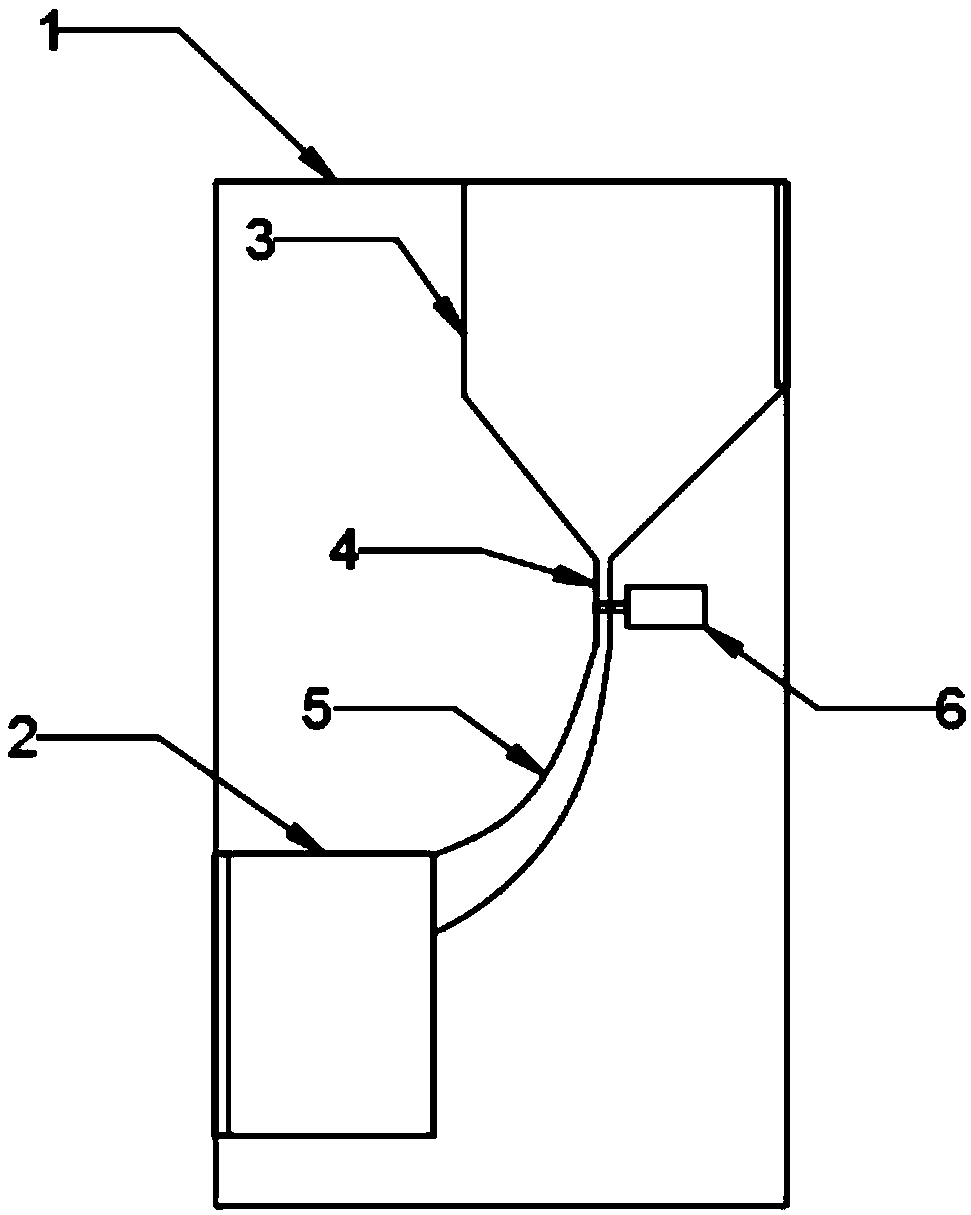

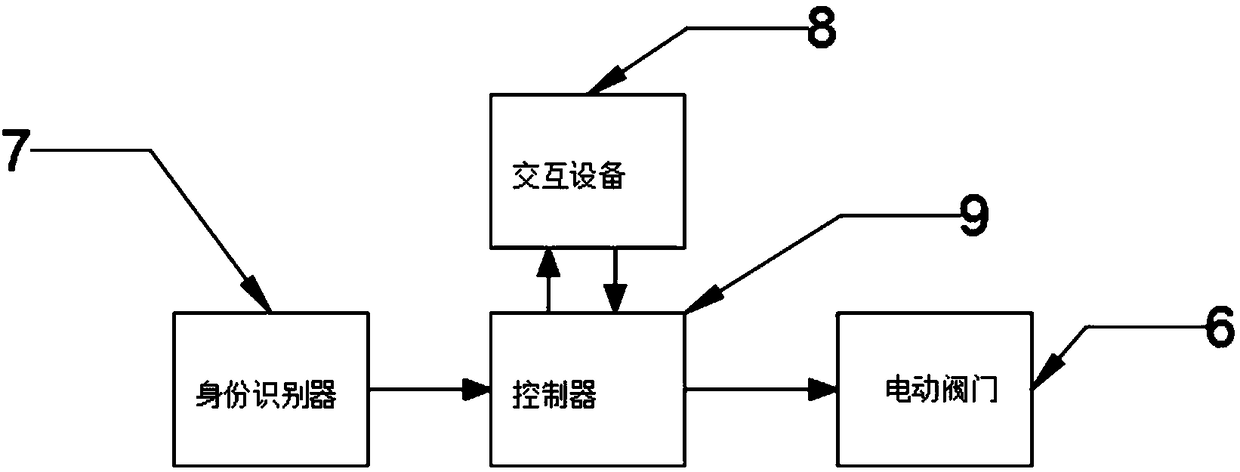

[0021] refer to Figure 1 to Figure 2 , a welding rod management cabinet, including a cabinet body 1, the cabinet body 1 is fixedly installed with a retrieving bin 2, a storage bin 3, an upper discharge channel 4, a lower discharge channel 5, an electric gate 6, The identification device 7 and the controller 9, the electric gate 6 is composed of a telescopic motor and a baffle plate installed on its head and extending into the upper discharge channel 4, the fetching bin 2 is installed under the storage bin 3, and The upper discharge channel 4 and the lower discharge channel 5 are connected successively. The upper discharge channel 4 is a cuboid cavity connected up and down. 2 times the diameter of the welding rod, the electric gate 6 is installed on the upper discharge channel 4, the opening and closing of the electric gate 6 makes the discharge channel switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com