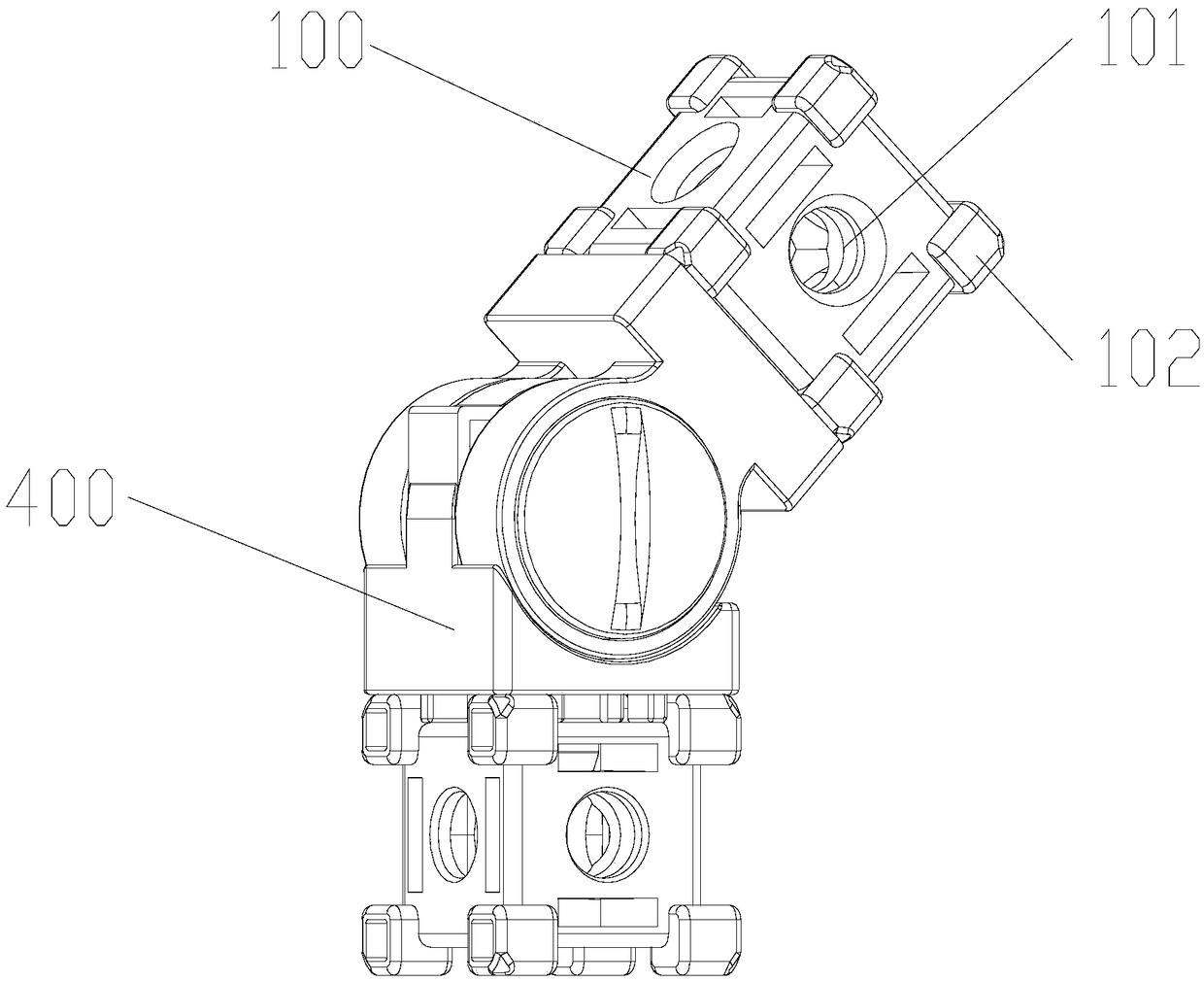

Assembled rotational conductive module

A conductive module, assembled technology, used in flexible/rotatable wire connectors, circuits, electrical components, etc., can solve the problems of easy falling off of the rotating shaft, damage to the rotating shaft, wire winding and twisting, etc., to save manpower and material costs. , Installation convenience and convenience, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

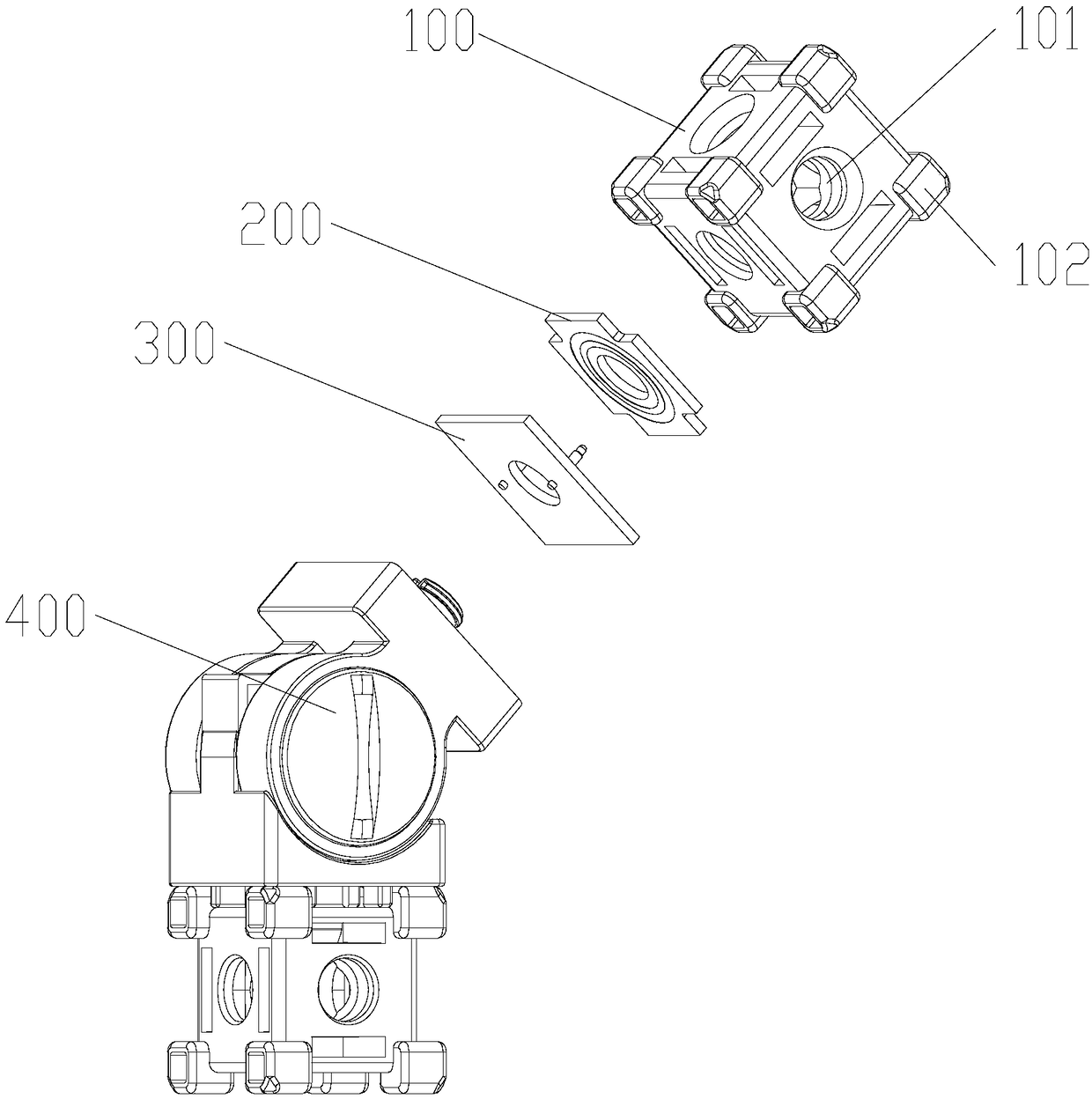

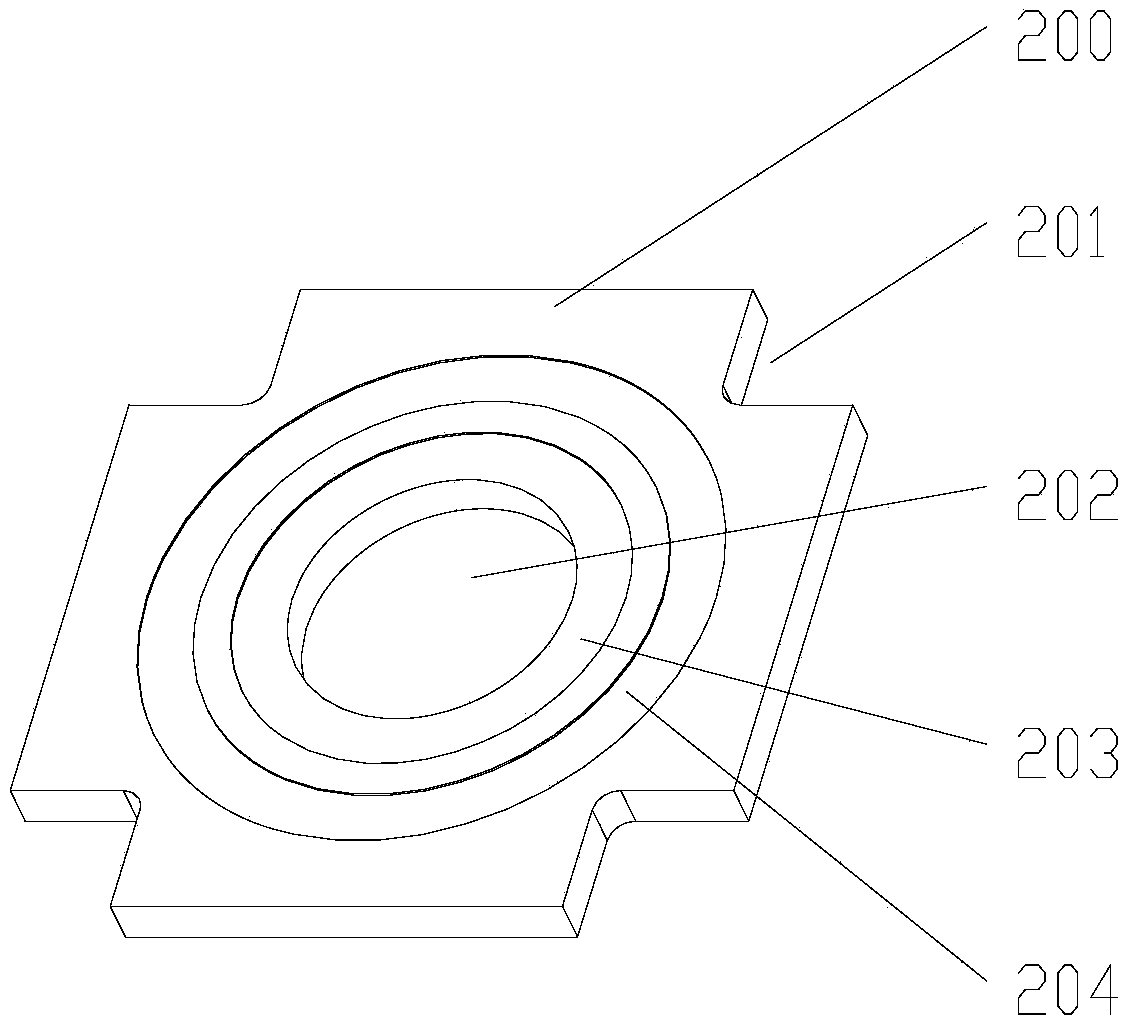

[0030] This embodiment provides an assembled rotating conductive module, including a structural module 100, a first PCB200, a second PCB300, and a hinge assembly 400. The structural module 100 is in the shape of a regular hexahedron, and six surfaces of the structural module 100 are respectively provided with circular cards. Button holes 101, eight corners of the structural module 100 are respectively provided with a protruding hexahedron, so that a protrusion 102 is formed at the four corners of each surface of the structural module 100; the first PCB200 is rectangular, and the four corners of the first PCB200 The corners are respectively provided with a notch 201 adapted to the raised portion 102; the first PCB200 is provided with a through hole a202; the surface of the first PCB200 is provided with an annular first conductive groove 203 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com