Orthotic insole capable of being transformed into custom insole rapidly and transformation method

An insole and fast technology, applied in insoles, footwear, clothing and other directions, can solve the problems of high labor cost and inconvenience, and achieve the effects of low cost, fast production speed and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

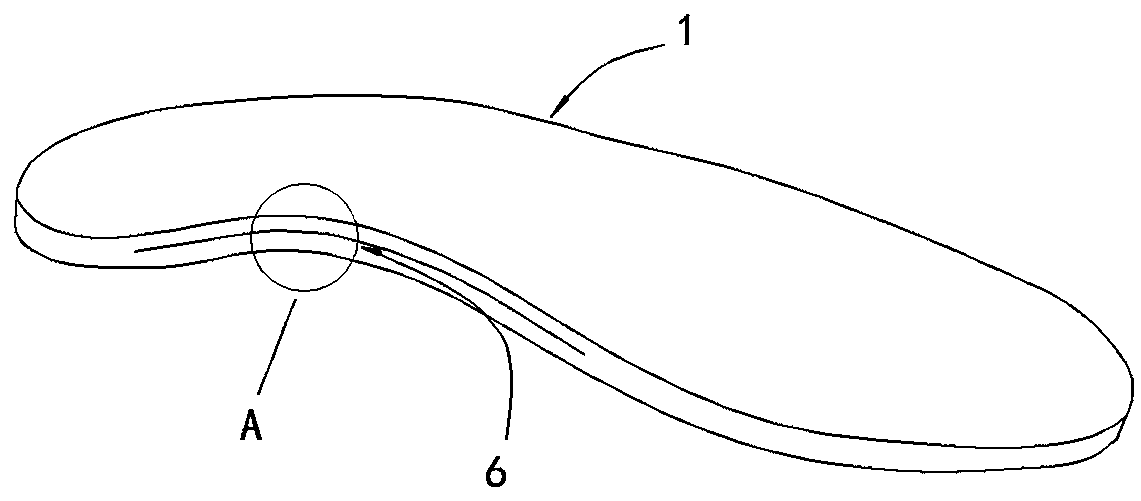

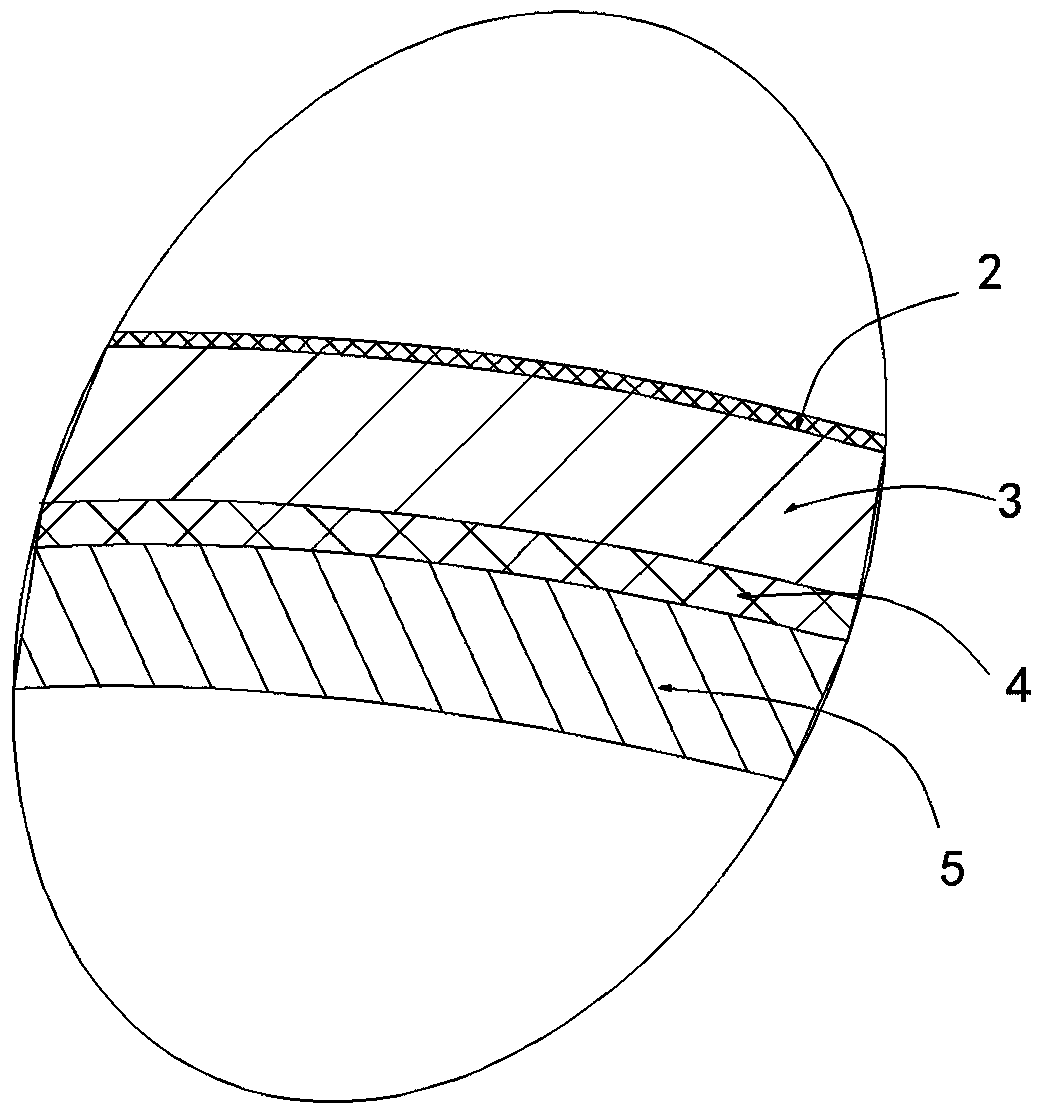

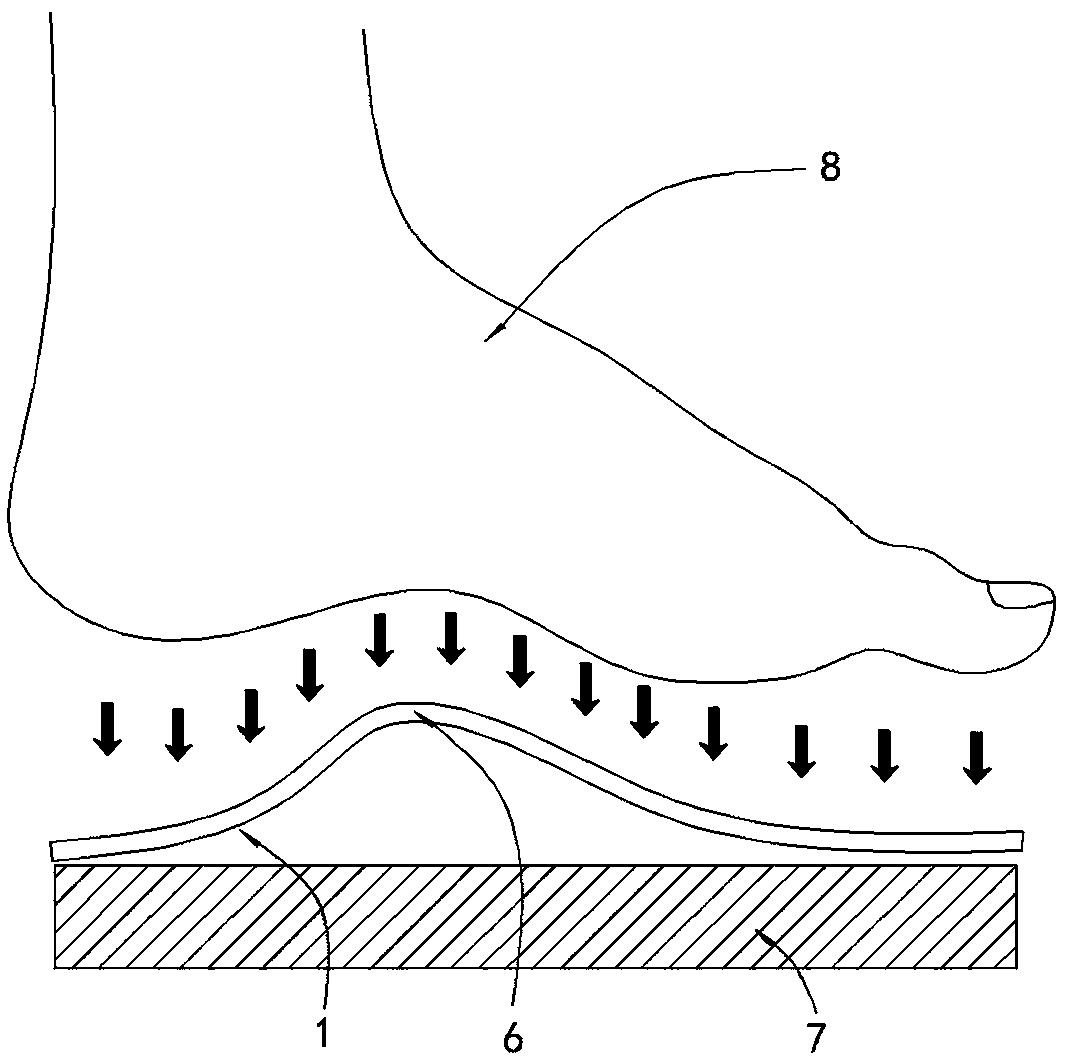

[0026] combined with Figures 1 to 4 , an orthopedic insole 1 that can be quickly transformed into a customized insole, the orthopedic insole 1 includes a contact layer 2, a cushioning layer 3, a thermoplastic layer 4, and a protective layer 5 from top to bottom, and the thermoplastic layer 4 is softened A low-temperature thermoplastic material with a temperature between 50 and 90 degrees Celsius, with peak-shaped undulations in the arch of the foot6.

[0027] The thermoplastic layer 4 is a plastic sheet, and the buffer layer 3 and the protective layer 5 are foamed plastics or other flexible materials commonly used to manufacture insoles, and the softening temperature is greater than 90 degrees Celsius. The contact layer 2 can be selected as a breathable and sweat-permeable textile material. The thermoplastic layer 4 is a plastic sheet, and the buffer layer 3 and the protective layer 5 are foamed plastics or other materials commonly used to manufacture insoles, and the softeni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com