Snap-fastener type rotating seal cup lid

A technology of snap buttons and cup lids, which is applied in the field of cup lids, can solve the problems of poor sense of consumers, small bolts, and unsuitability for enterprises with a large amount of use, so as to increase heat preservation and sanitation, facilitate quick installation, The effect of reducing food safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

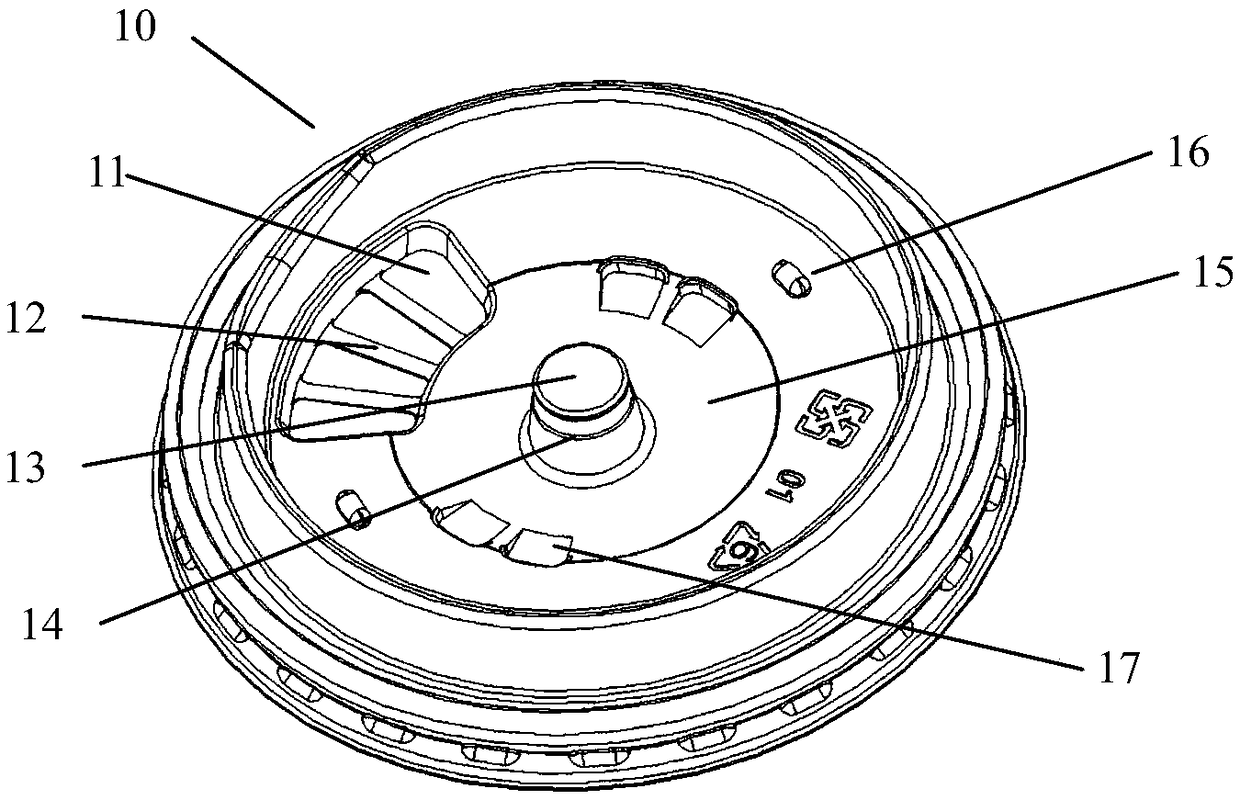

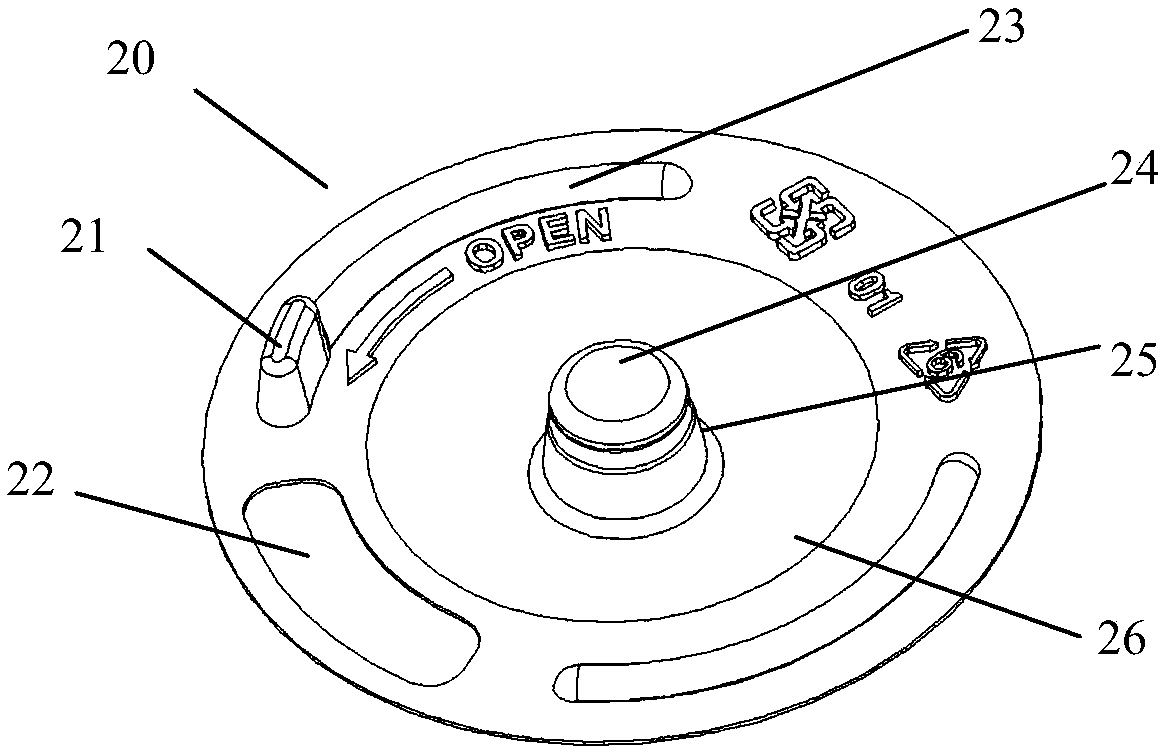

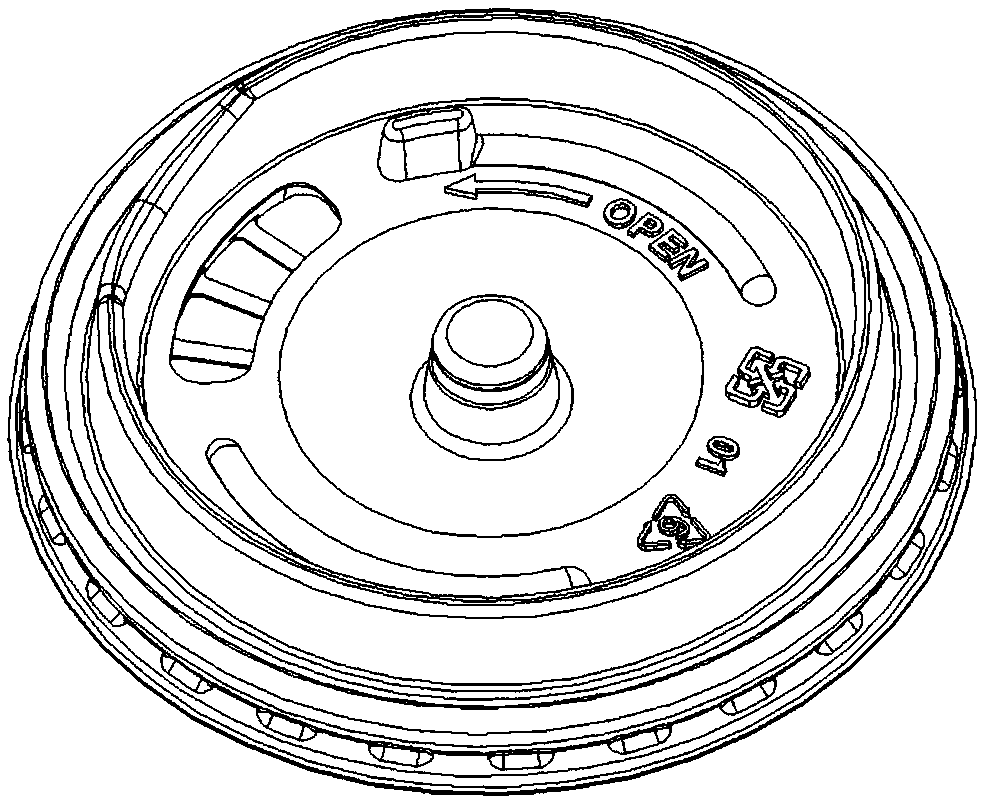

[0031] A snap-type rotary-seal cup lid comprises a lid body 10 and a rotary card 20 . The structure of cover body 10 is as figure 1 As shown, there is at least one drinking port 11, and a fence-shaped tea filter port 12 can be provided at the drinking port 11 to prevent a large piece of tea from flowing into the port and affect the taste of consumers. In the center of the cover body 11, there is a male snap button 13 There is a matching groove 14 on it, which is used to cooperate with the protrusion 25 on the female snap button 24 on the rotating card 20, and is used to fix the rotating card 20 like a snap button. The top of the cover body 15 is a concave spherical top, which is convenient for cups In the beverage condensed water return cup, one or several position-limiting protrusions 16 are provided on the cover body to limit and guide the rotation chute 23 on the rotating card 20, and the cover body is provided with a reinforcing block 17 for Enhance the strength of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com