A Method for Determining the Instantaneous Position of Holding Roller in Special-shaped Ring Rolling

A technology of instantaneous position and special-shaped rings, applied in metal rolling, complex mathematical operations, etc., can solve problems such as complex motion control of rolling rolls and inapplicability of rolling rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

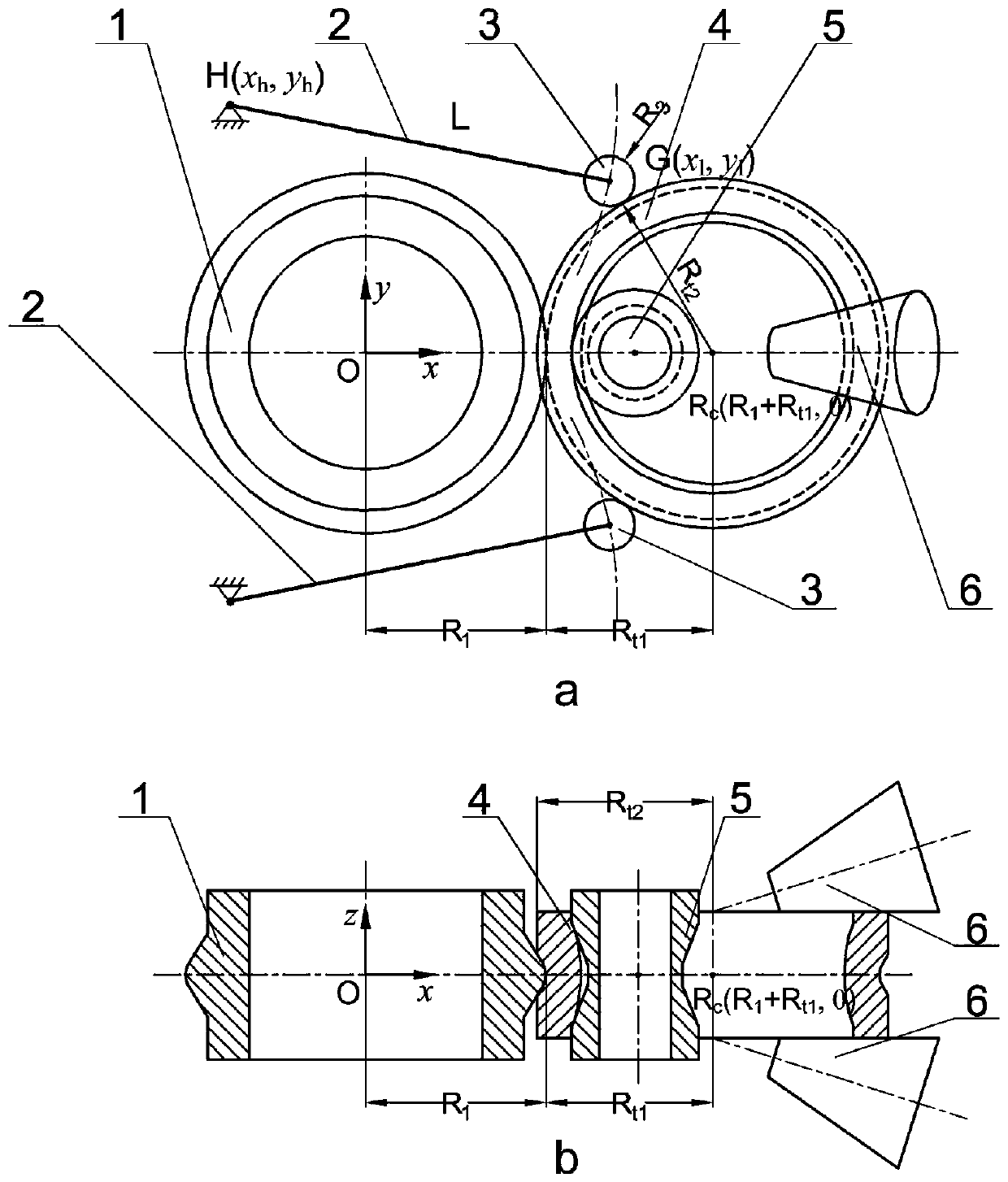

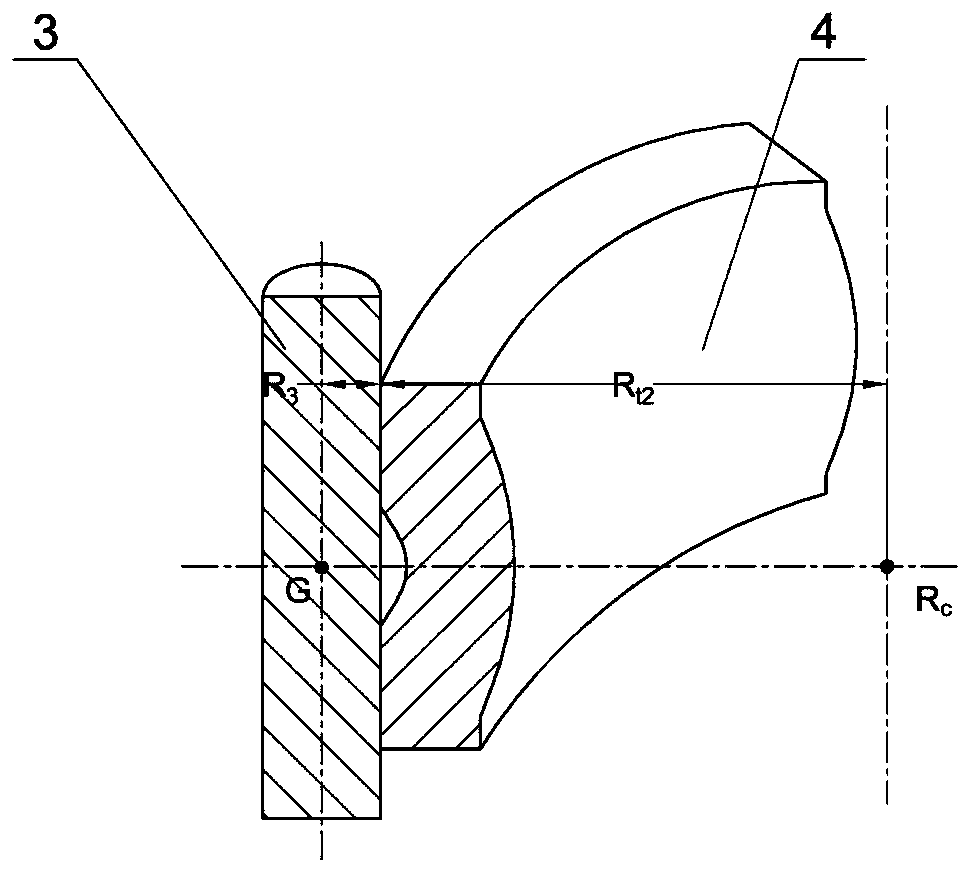

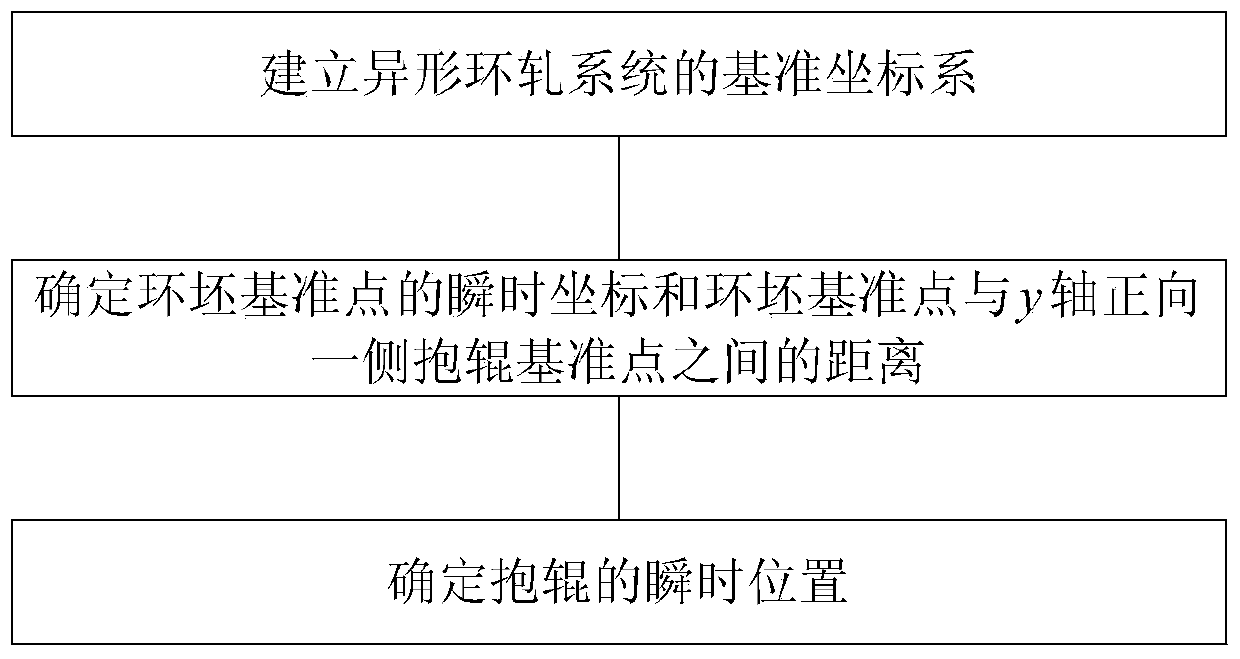

[0047] This embodiment is a method for determining the instantaneous position of the holding rolls in special-shaped ring rolling. By establishing the reference coordinate system of the special-shaped ring rolling system, the relative positional relationship between the components of the entire ring rolling system can be determined. Then determine the radii (R 1 and R 3 ) and the instantaneous radius of the ring blank at the corresponding contact (R t1 and R t2 ), to obtain the instantaneous coordinate R of the reference point of the ring blank c (R 1 +R t1 ,0) and the distance between the reference point of the ring blank and the reference point of the roll on the positive side of the y-axis (R 3 +R t2 ). Then, according to the determined relative positional relationship, list the equations about the instantaneous coordinates of the roll reference point on the positive side of the y-axis, and solve to obtain the instantaneous coordinate formula of the roll reference po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com