Automatic protection carrier for cargoes

A technology for handling vehicles and goods, applied in the field of automatic protection of goods handling vehicles, can solve the problems of easy shaking of goods, affecting the working efficiency of forklifts, inconvenient use of protective mechanisms, etc., and achieves protection guarantee, simple and ingenious structure, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

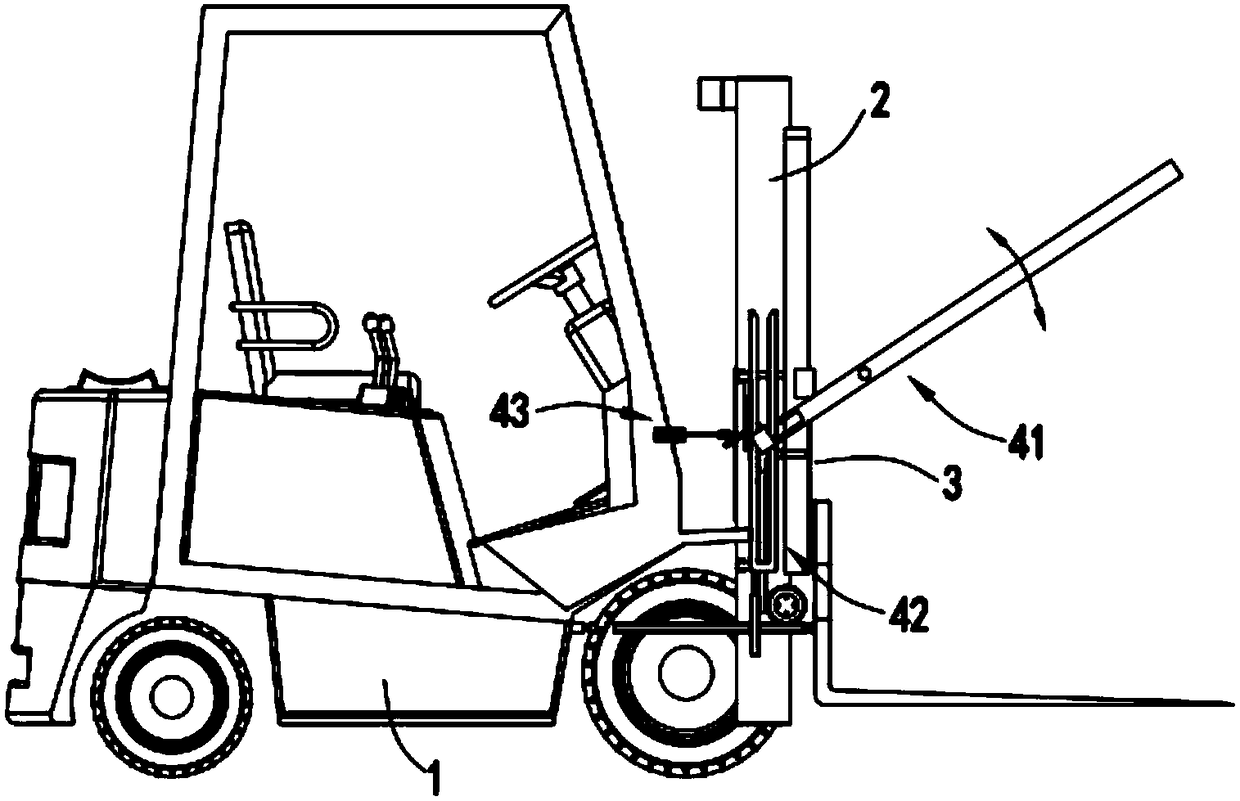

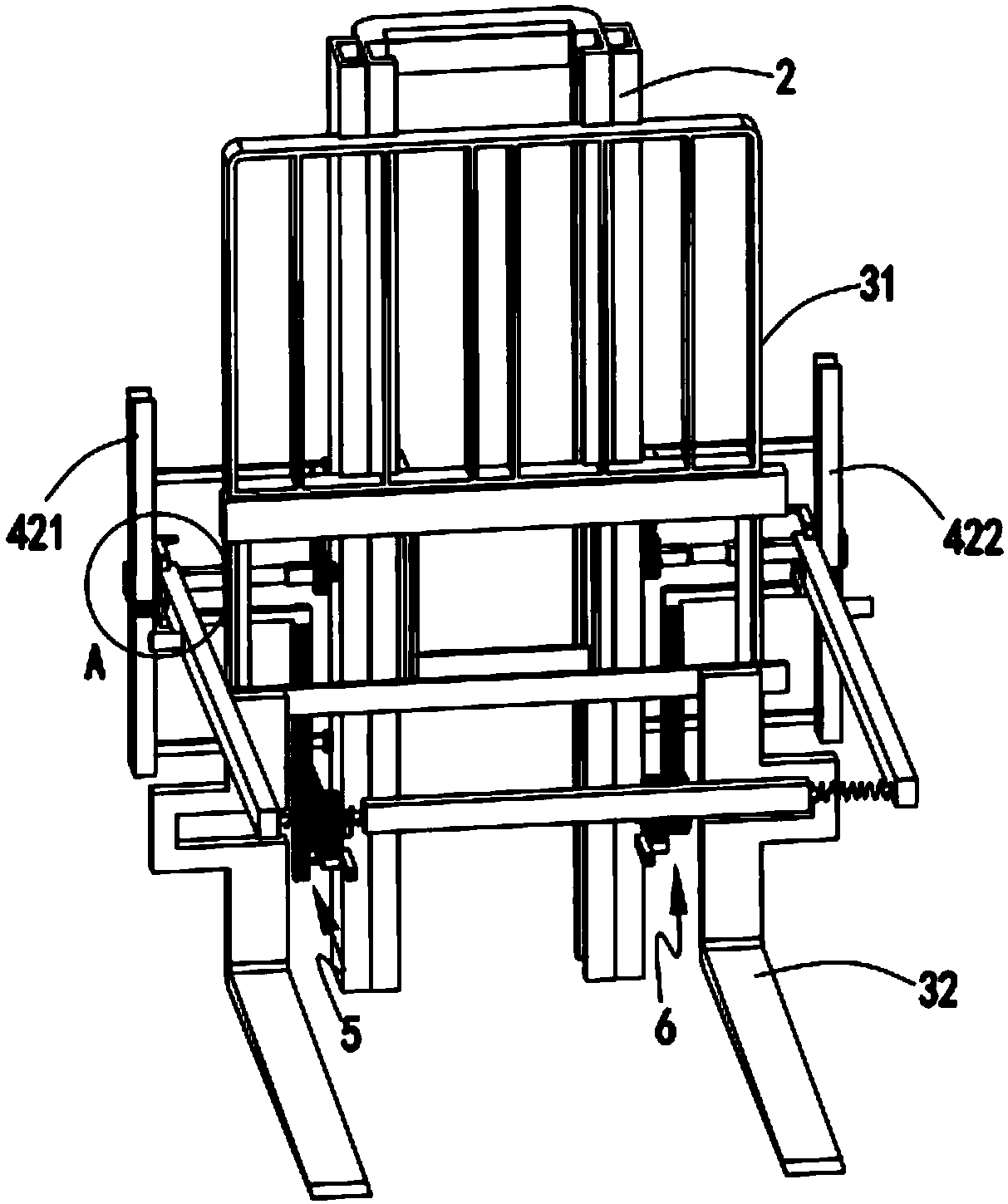

[0043] like Figure 1 to Figure 10 As shown, a kind of cargo automatic protection transporter includes a forklift main body 1, a mast 2 arranged at the front of the forklift main body 1, a shelf 3 that moves up and down along the mast 2, and also includes a protective device 4 and a first retractable device 5 And the second retractable device 6, the protective device 4 includes a protective mechanism 41 for protecting the goods on the shelf 3, a guiding mechanism 42 for guiding and limiting the protective mechanism 41, and a guiding mechanism 42 for driving the protective mechanism 41 to retract tight tightening mechanism 43;

[0044]The first retractable device 5 and the second retractable device 6 are symmetrically arranged on both sides of the protective device 4, and the first retractable device 5 and the second retractable device 6 are used to jointly control the opening or retraction of the protective mechanism 41 The first retracting device 5 and the second retracting ...

Embodiment 2

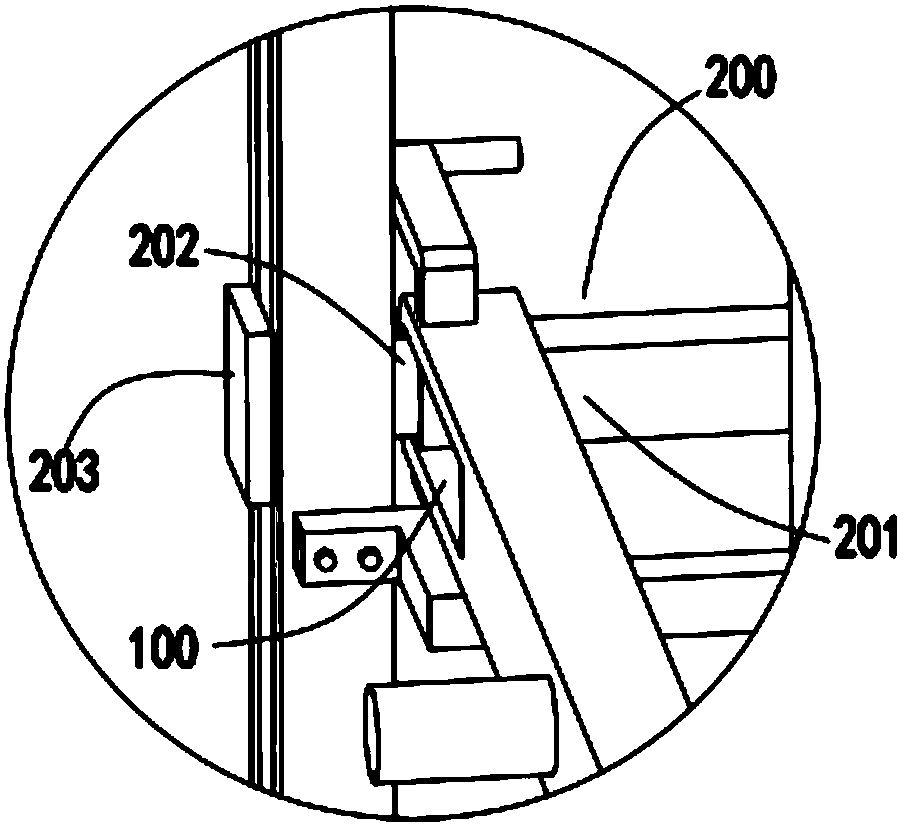

[0062] like Figure 4 and Figure 5 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is: further, the limit assembly 521 can rotate the third gear 5211 arranged on the side of the door frame 2 and the third gear 5211 fixed on the outer end surface of the third gear 5211. A limiter 5212, the limiter 5212 is provided with a card slot 5213, and correspondingly, at one end of the sliding part 201 of the connector 200 opposite to the limiter 202, a limiter that matches the card slot 5213 is provided. Position block a5214, when the limit block a5214 is completely engaged in the slot 5213, the limit part 202 and the third gear 5211 are coaxial;

[0063] The turning assembly 522 includes a thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com