Ball valve with valve body self-sealing mechanism

A self-sealing, valve body technology, applied in the valve shell structure, valve operation/release device, valve details, etc., to achieve the effect of expanding the scope of use scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

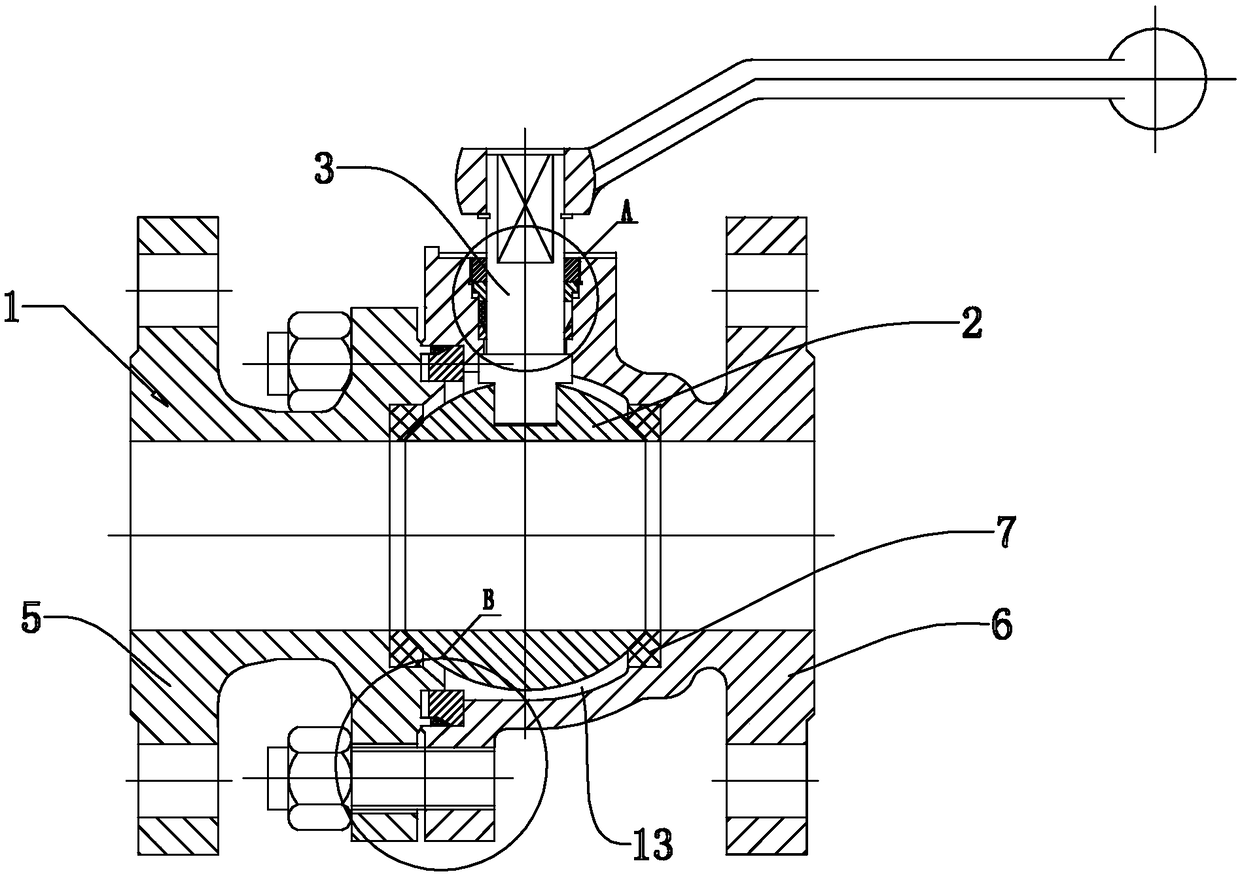

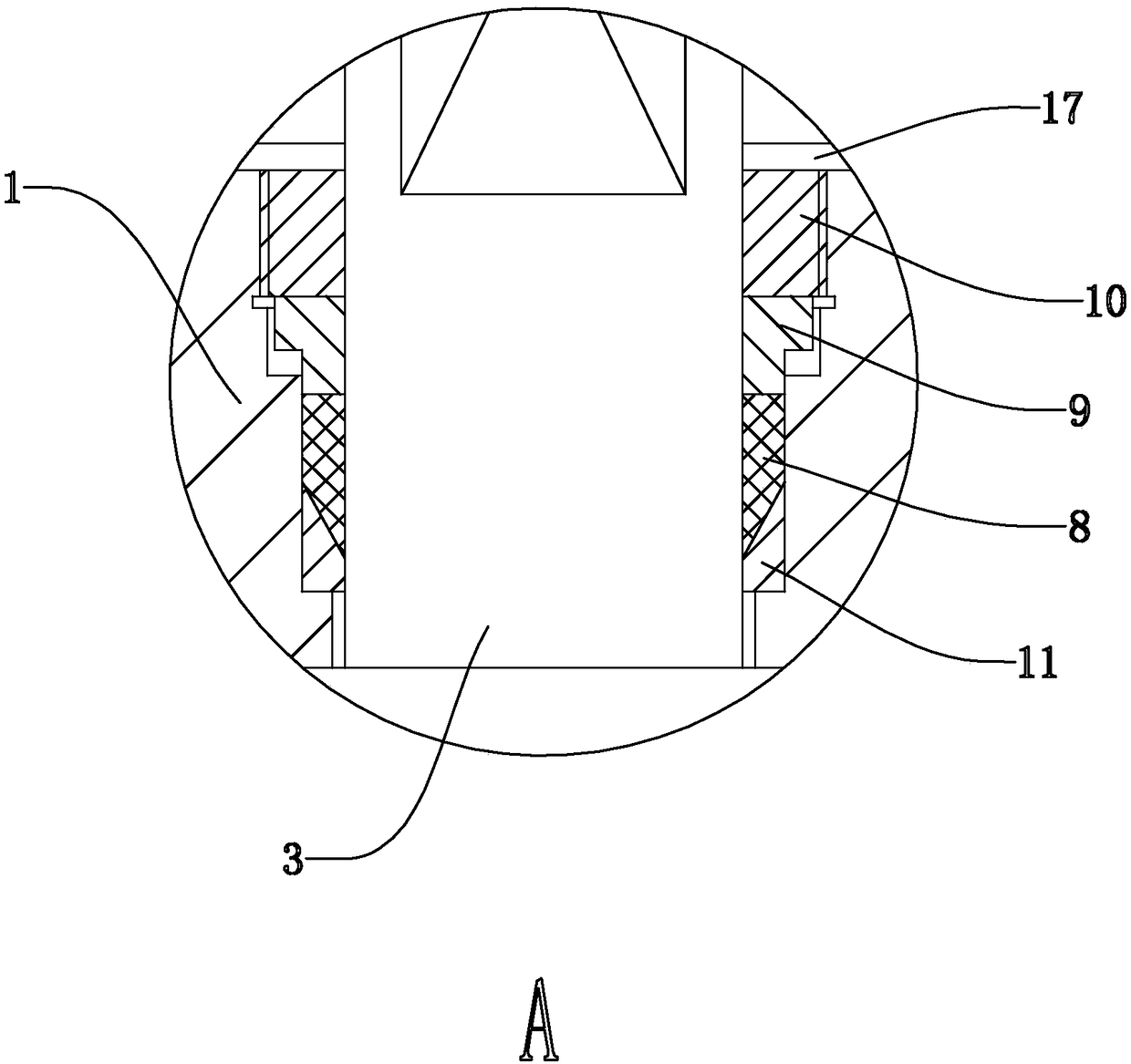

[0027] Such as figure 1 with figure 2 As shown, a ball valve with a valve body self-sealing mechanism includes a valve body 1, a ball 2, a valve stem 3 and a drive unit for driving the valve stem 3, and the valve body 1 is fixedly connected by a left valve body 5 and a right valve body 6 Formed, the valve body 1 is provided with a valve seat 7 . The valve body 1 is provided with an accommodating cavity 13 , and the ball 2 is placed in the accommodating cavity 13 . A first molding packing 8 is arranged between the valve body 1 and the valve stem 3, and a packing gland 9 for pressing the first molding packing 8 is arranged above the first molding packing 8, and the packing gland 9 is far away from the first molding packing 8. One side is provided with an adjusting nut 10 that drives the packing gland 9 to perform the operation of compressing the first molding packing 8; for the slope.

[0028] When the pressure in the accommodating chamber 13 is low pressure, the gland move...

Embodiment 2

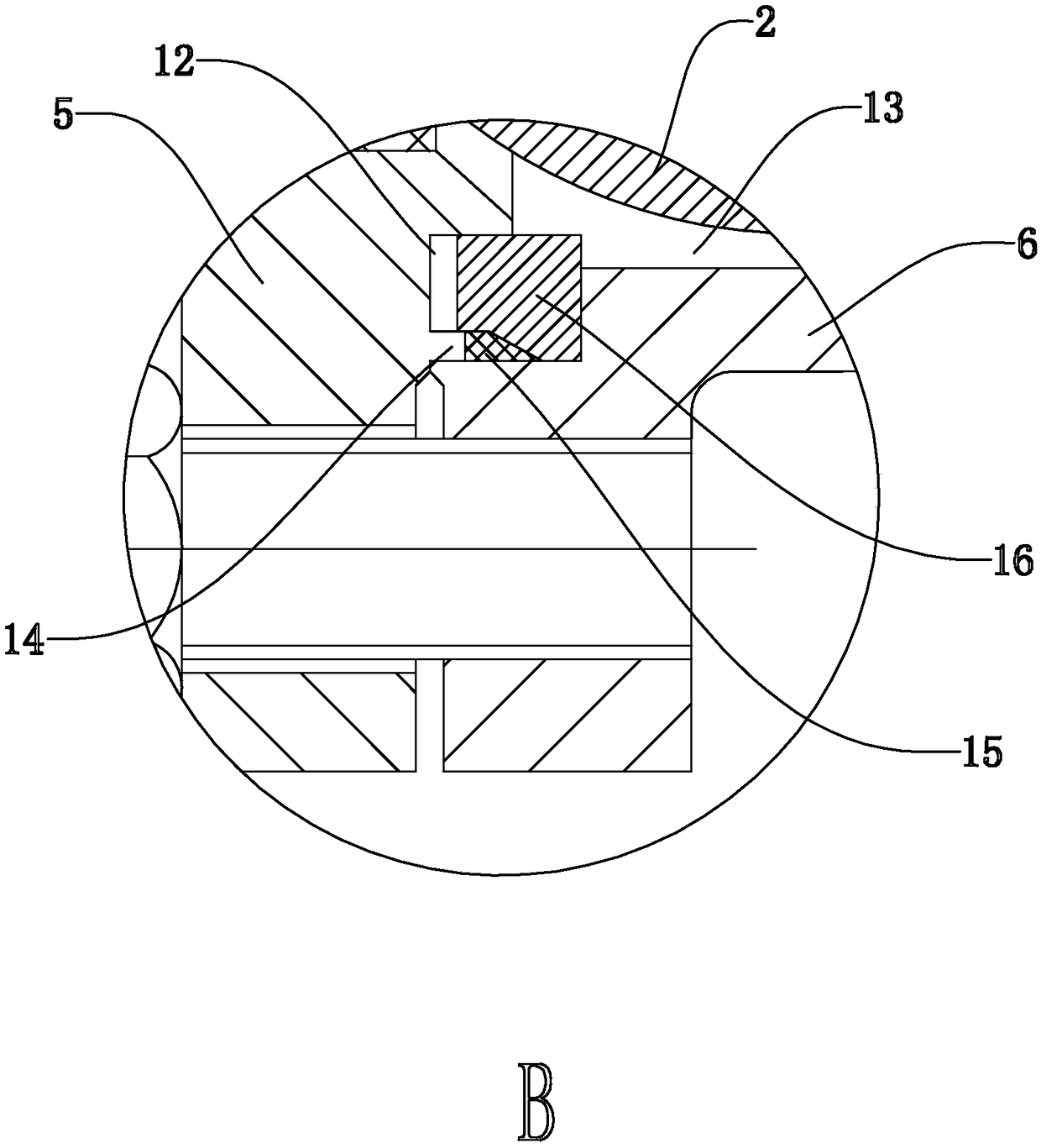

[0036] Such as Figure 4 , Figure 5 with Image 6 As shown, the difference from the first embodiment is that the gasket 16 includes a metal skeleton 18 and a rubber sealing body 19 that can cover the metal skeleton 18 . Both the metal skeleton 18 and the rubber sealing body 19 are ring-shaped, and the metal skeleton 18 can improve the structural strength of the rubber sealing body 19, making the rubber sealing body 19 suitable for different pressure requirements and pressure environments, so as to expand the range of use scenarios.

[0037] The side of the rubber sealing body 19 close to the left valve body 5 is provided with two parallel outer sealing lips 20 , and the two outer sealing lips 20 are respectively aligned with the two end surfaces of the rubber sealing body 19 . A groove 21 is formed between the two outer sealing lips 20, and grease is applied in the groove 21. Since the rubber sealing body 19 will move in the slideway 12 under the high pressure environment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com