Method for high flux melting sintering device developed based on idea of movable type printing

A technology of movable type printing and sintering device, applied in the field of high-flux melting and sintering device, can solve the problems of few samples and low efficiency, and achieve the effect of improving efficiency and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below by means of specific embodiments:

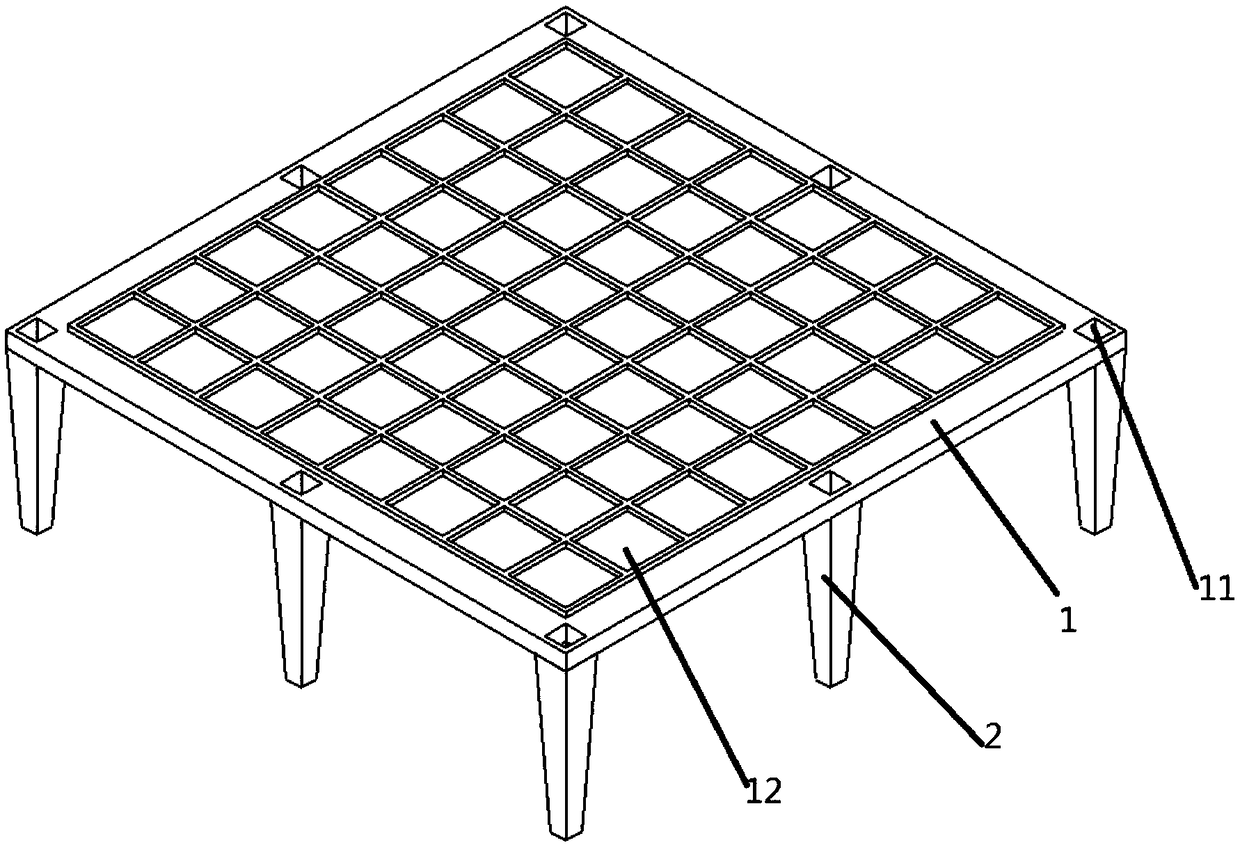

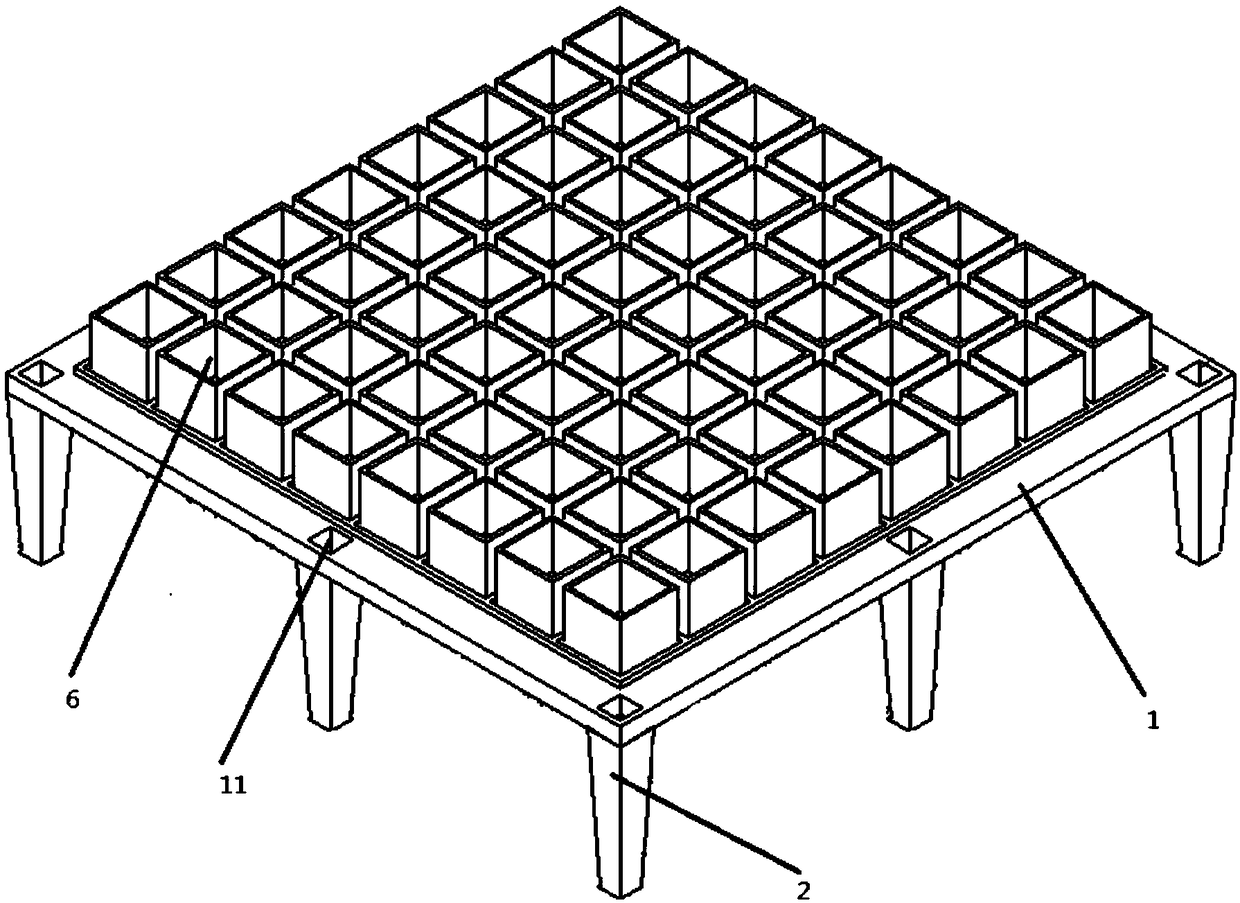

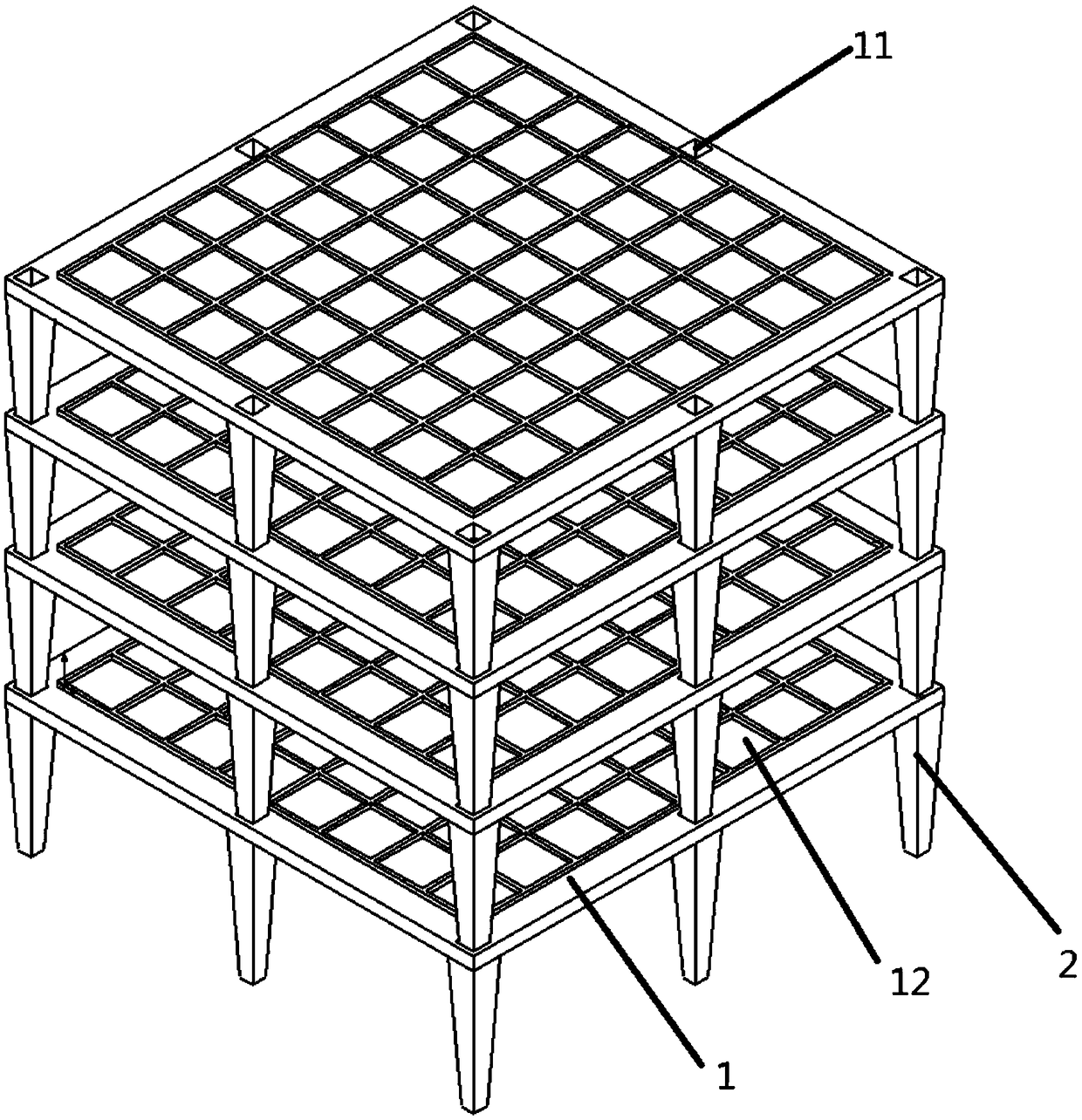

[0035] The reference signs in the drawings of the specification include: crucible frame plate 1, installation hole 11, limit hole 12, gas storage chamber 13, air guide hole 14, exhaust hole 15, support foot 2, cavity 21, air inlet 22 , suction hole 23, air intake hole 24, sleeve 3, through hole 31, piston barrel 4, piston 41, push rod 42, block 5, crucible 6.

[0036] The embodiment is basically as attached figure 1 Shown:

[0037] Such as Figure 5 As shown, a high-throughput melting and sintering device developed based on the idea of movable type printing includes a crucible frame plate 1, and the crucible frame plate 1 is made of alumina or boron nitride among high-temperature resistant materials. This embodiment is made of alumina . The upper surface of the crucible frame plate 1 is provided with grid-shaped limiting holes 12 arranged in a matrix, and the limiti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com