High-strength Fe-Cr-Ni-Al multiplex stainless steel and manufacturing method therefor

A fe-cr-ni-al, stainless steel technology, applied in the field of high-strength Fe-Cr-Ni-Al multi-phase stainless steel, can solve the unsuitable manufacturing and application of thin nuclear fuel cladding, limited processability and bonding properties , degradation of mechanical properties, etc., to achieve excellent accident tolerance, excellent integrity, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

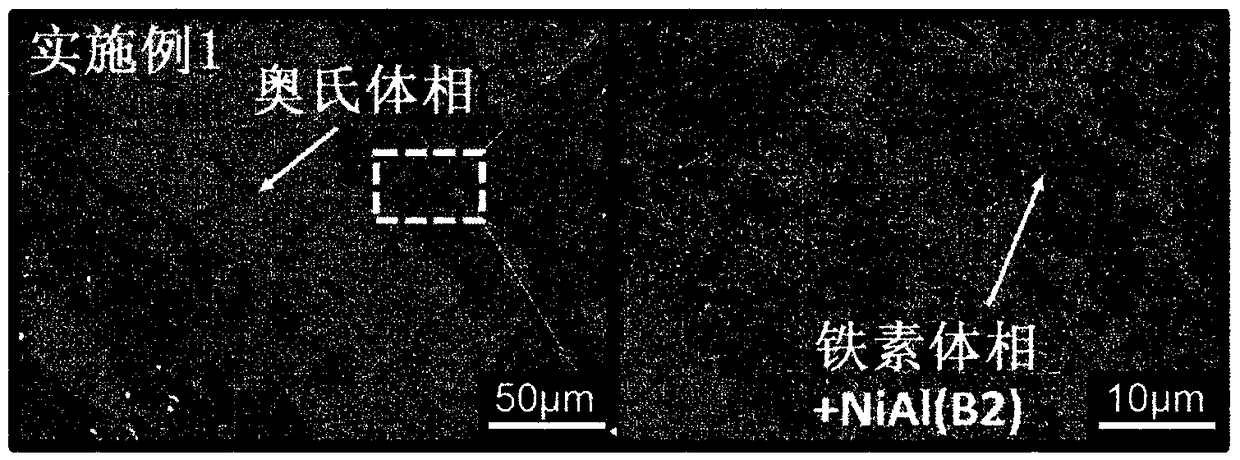

[0062] Embodiment 1.Fe-Cr-Ni-Al alloy

[0063]First, 46.67% by weight of iron (Fe), 23.64% by weight of chromium (Cr), and 24.15% by weight of nickel were melted at a melting temperature of 1300°C under an argon atmosphere of 450 Torr using a vacuum induction melting reactor. (Ni), 5.54% by weight of aluminum (Al), and based on 100 parts by weight of a combination of iron (Fe), chromium (Cr), nickel (Ni) and aluminum (Al), 0.48 parts by weight of Nb, 1.01 parts by weight Mn, 0.12 parts by weight of C, 0.31 parts by weight of Si and 0.0080 parts by weight of Ti for 2 hours. Then, a steel ingot of 42 kg was subjected to homogenization and solution annealing heat treatment at 1200° C. for 3 hours in an air furnace, and then subjected to cooling in the furnace to obtain a block having a thickness of 30 mm. Thereafter, hot rolling was performed at 1150° C. 8 times to obtain an alloy having a thickness of 3 mm.

[0064] The rolled alloy was subjected to a preliminary heat treatmen...

Embodiment 2

[0065] Embodiment 2.Fe-Cr-Ni-Al alloy

[0066] In addition to using 52.11% by weight of iron (Fe), 20.96% by weight of chromium (Cr), 21.48% by weight of nickel (Ni), 5.50% by weight of aluminum (Al), and based on 100 parts by weight of iron (Fe), chromium (Cr), nickel (Ni) and aluminum (Al) combination of 0.52 parts by weight of Nb, 1.04 parts by weight of Mn, 0.12 parts by weight of C, 0.32 parts by weight of Si and 0.0056 parts by weight of Ti, repeating Example 1 to obtain stainless steel.

Embodiment 3

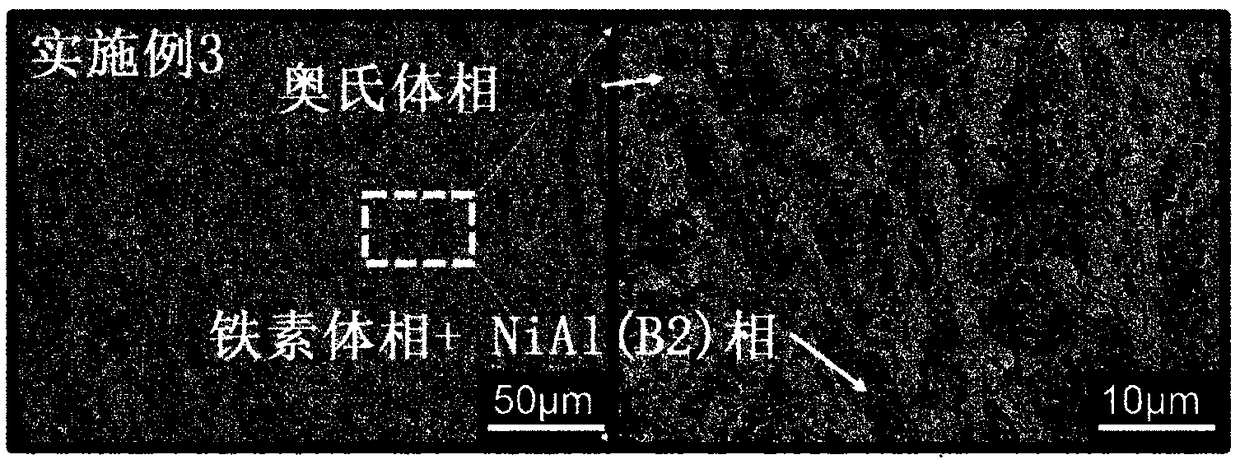

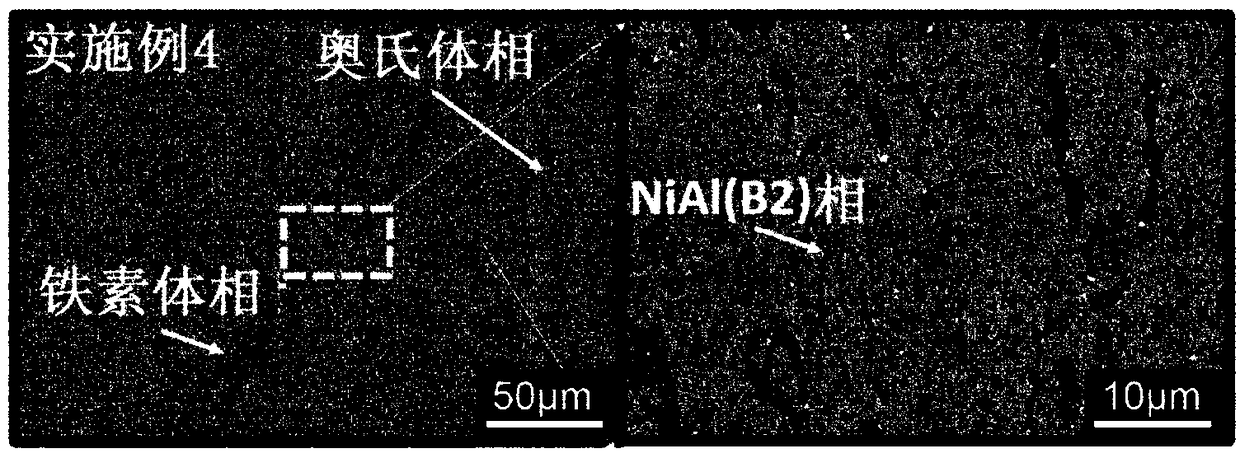

[0067] Embodiment 3.Fe-Cr-Ni-Al alloy

[0068] In addition to using 58.76% by weight of iron (Fe), 16.33% by weight of chromium (Cr), 18.77% by weight of nickel (Ni), 6.14% by weight of aluminum (Al), and based on 100 parts by weight of iron (Fe), chromium (Cr), nickel (Ni) and aluminum (Al) combination of 0.53 parts by weight of Nb, 1.04 parts by weight of Mn, 0.11 parts by weight of C and 0.31 parts by weight of Si, Example 1 was repeated to obtain stainless steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com