Joint for torque transmission, and electric power steering device

A technology for torque and transmission components, applied in the field of torque transmission joints and electric power steering devices, can solve problems such as abnormal noise, and achieve the effect of suppressing abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0117] [the first example of embodiment]

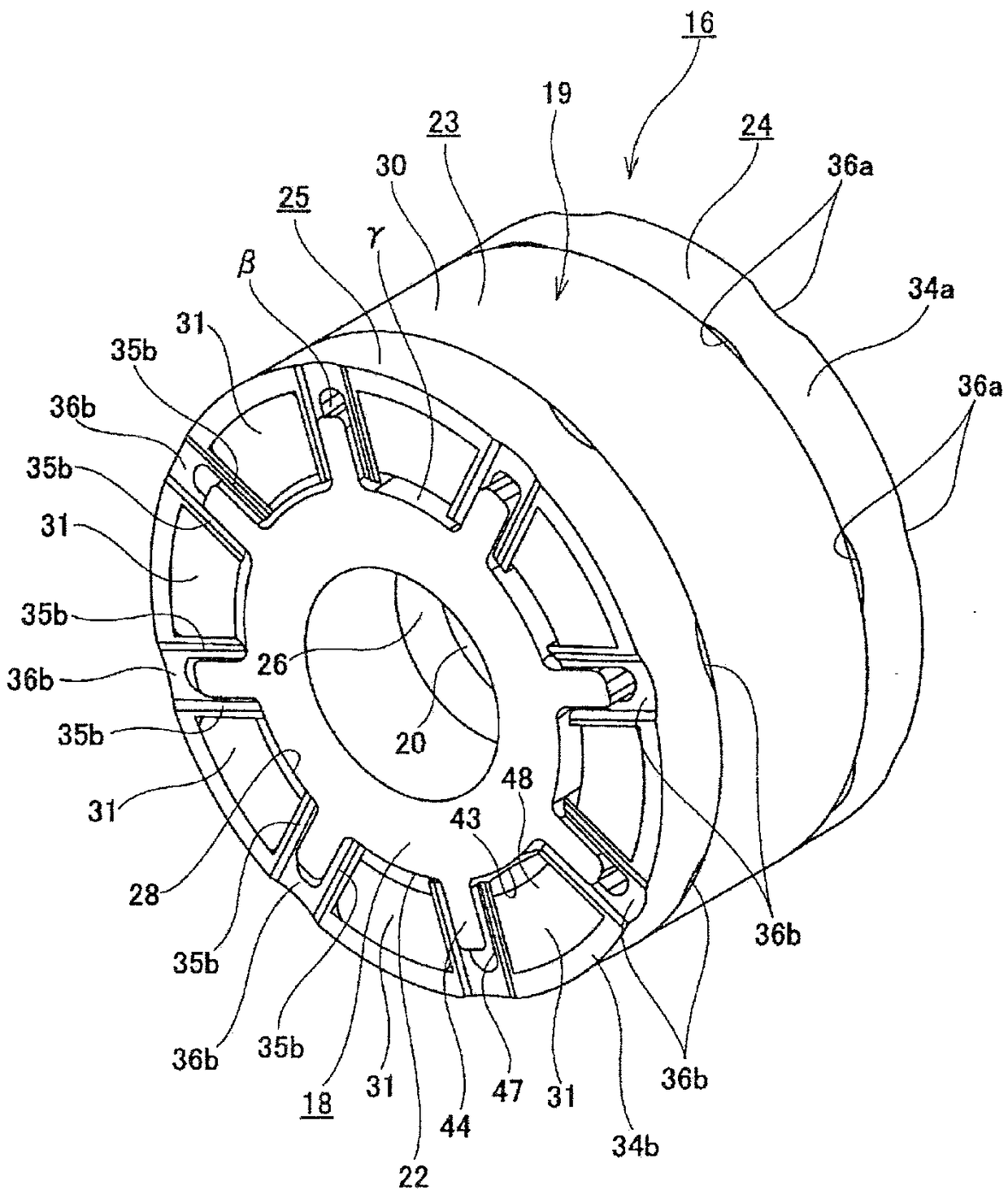

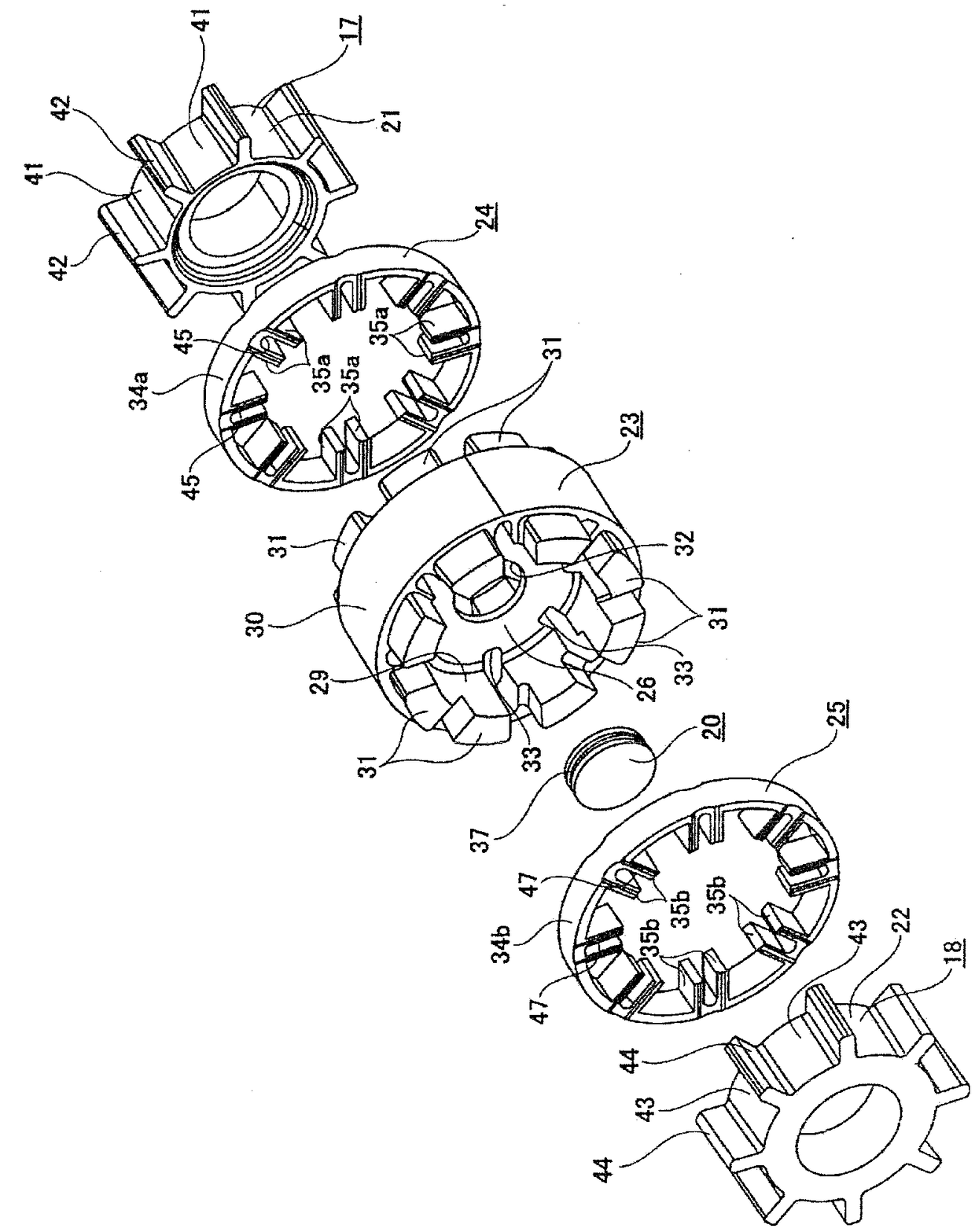

[0118] pass Figure 1-14 A first example of an embodiment of the present invention will be described.

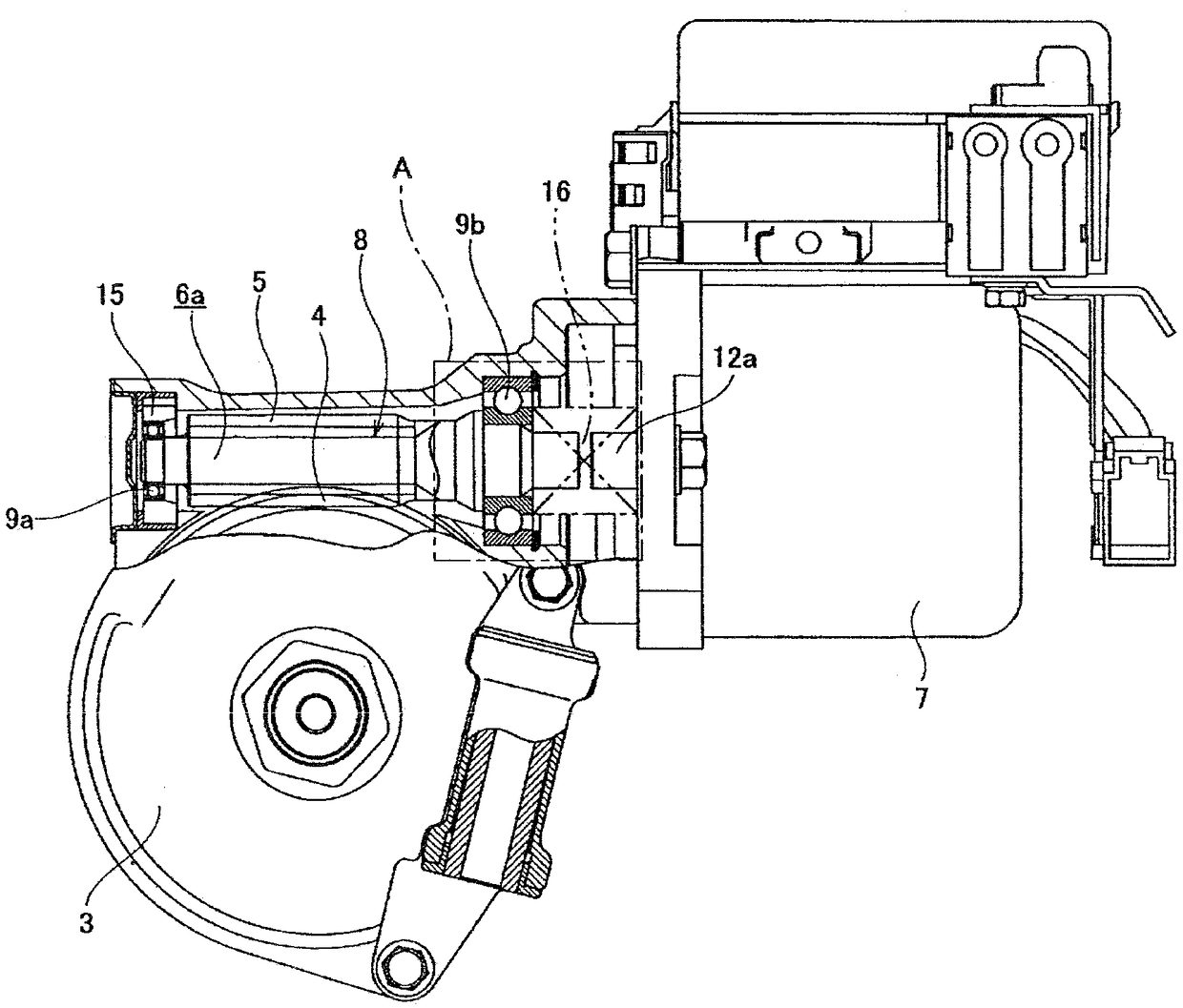

[0119] The electric power steering device of this example is the same as the above-mentioned Figure 23-24 In the conventional structure shown, the steering wheel 1 is attached to the rear end of the steering shaft 2 , the front end of the steering shaft 2 is rotatably supported in the housing 3 , and the worm wheel 4 is fixed to the part driven by the steering shaft 2 . A worm tooth 5 meshing with the worm wheel 4 is provided at an axially intermediate portion of the worm shaft 6a. Both ends in the axial direction of the worm 8 rotationally driven by the electric motor 7 are rotatably supported in the housing 3 by a pair of rolling bearings (ball bearings in the illustrated example) 9a, 9b. Further, the worm gear 5 provided on the worm shaft 6a is pressed against the worm wheel 4 by providing the preload imparting mechanism 15 be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com