Waste gate valve control method and control device

一种废气旁通阀、控制方法的技术,应用在电气控制、电动发动机控制自动控制、燃气轮机装置等方向,能够解决易产生异常噪音、阀体振动等问题,达到抑制异常噪音的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, an embodiment of the present invention will be described in detail based on the drawings.

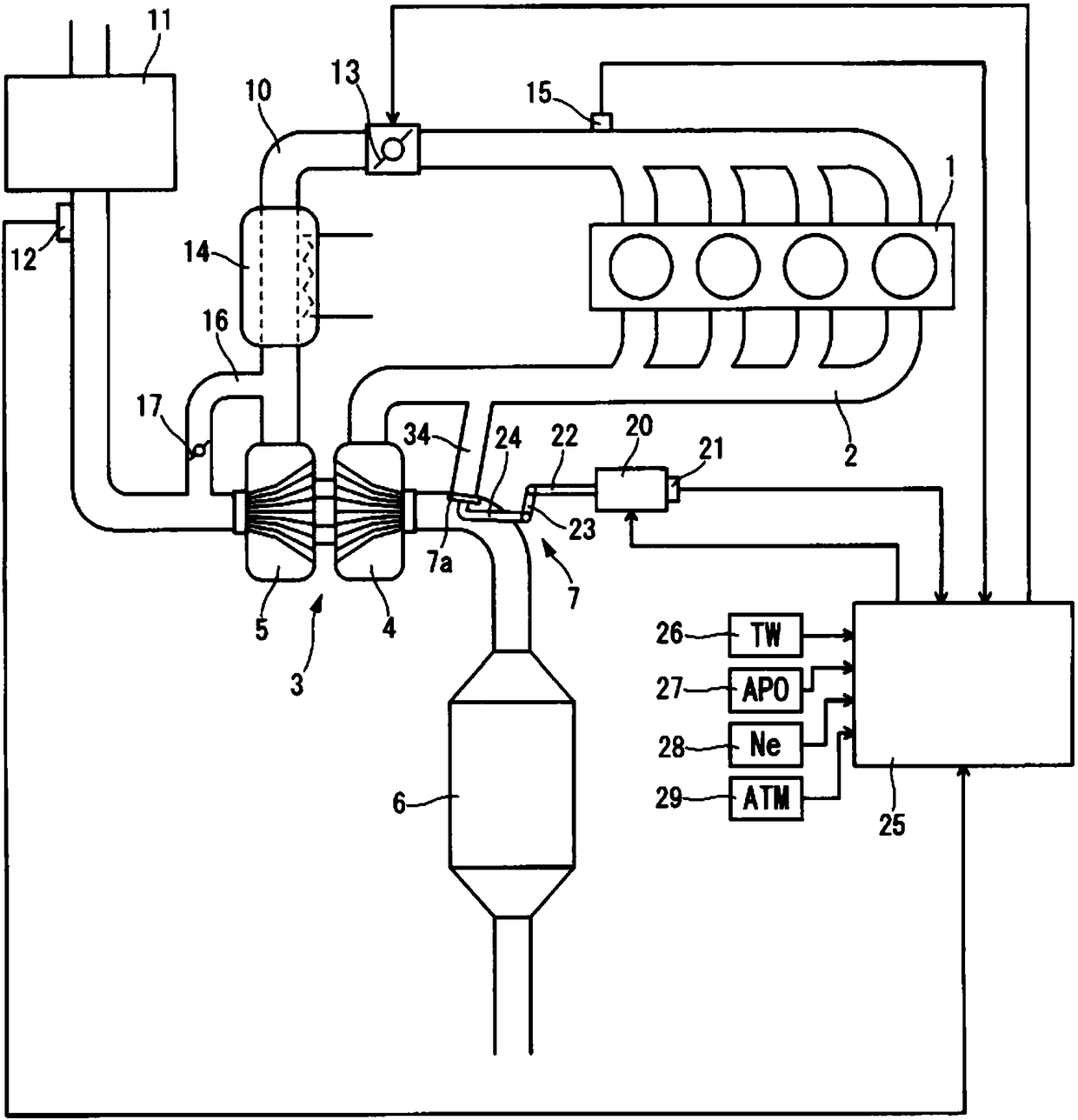

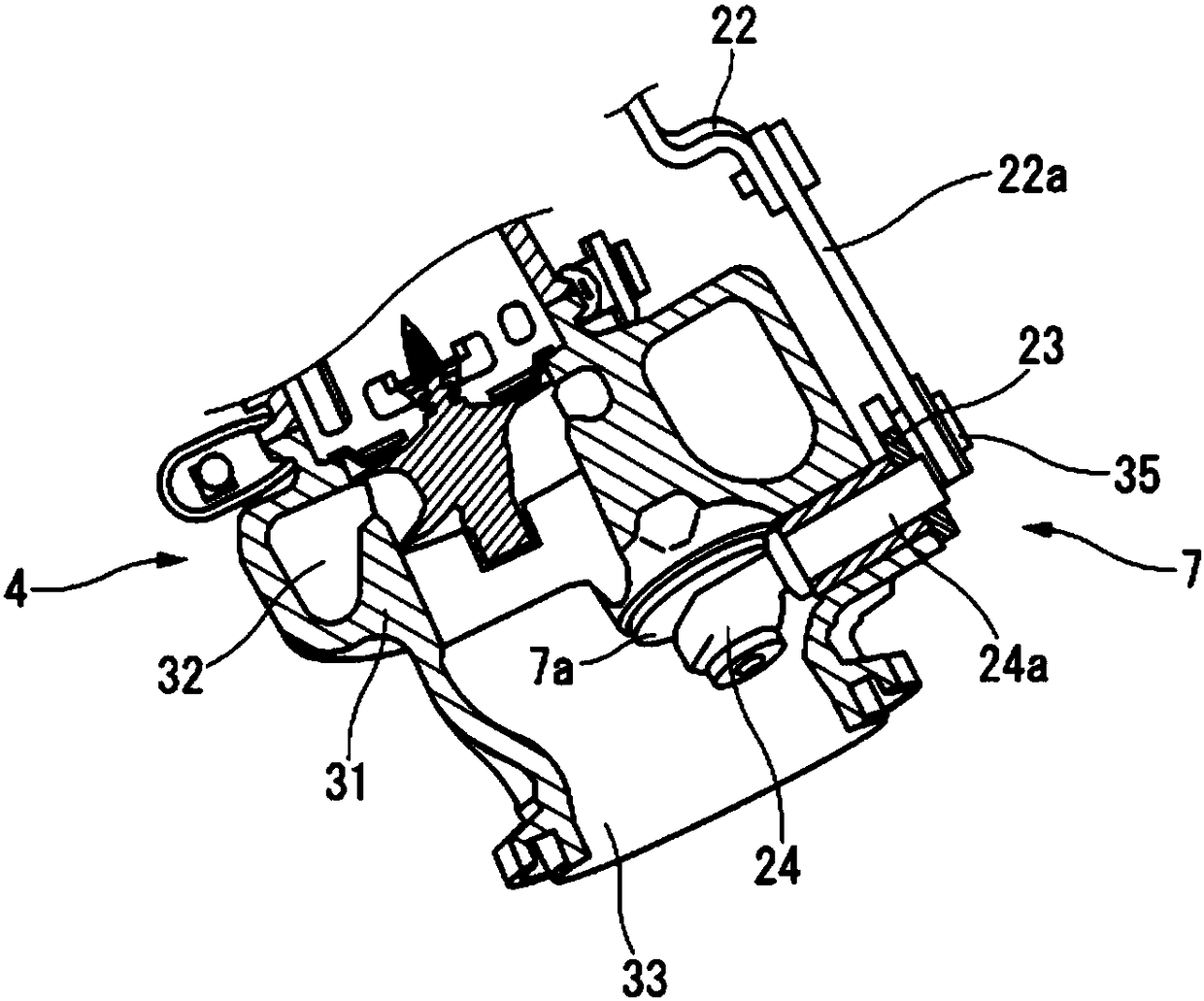

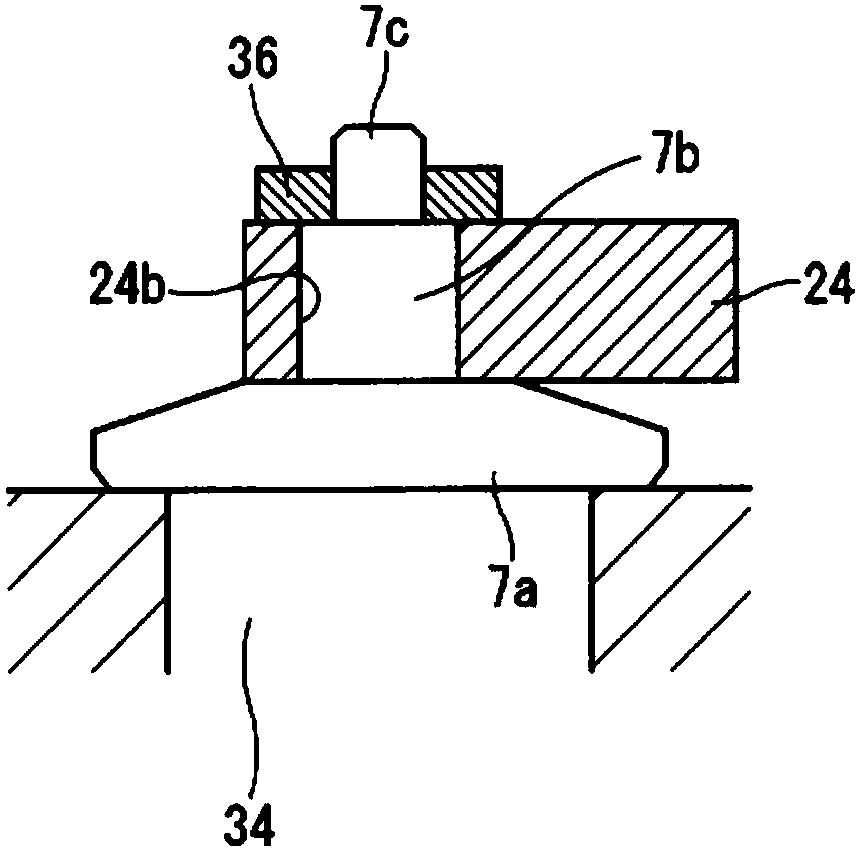

[0017] figure 1 It is a configuration explanatory diagram showing a system configuration of an embodiment of the present invention, in which an exhaust turbine 4 of a turbocharger 3 is arranged in an exhaust passage 2 of an internal combustion engine 1 which is a spark ignition type gasoline internal combustion engine, and an exhaust turbine 4 of a turbocharger 3 is arranged on the downstream side thereof. For example, the catalytic converter 6 using a three-way catalyst. An exhaust muffler (not shown) is provided further downstream of the exhaust passage 2, and the exhaust passage 2 is opened to the outside through the exhaust muffler. The exhaust turbine 4 is provided with a wastegate 7 for supercharging pressure control. In addition, the internal combustion engine 1 is, for example, of a direct-injection type, and has a fuel injection valve (not shown) for injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com