Power transmission mechanism and multi-shaft drive device

A technology of power transmission mechanism and connecting mechanism, which is applied in the direction of transmission, mechanical drive clutch, special position of the vehicle, etc., can solve the problem of a large number of motors, and achieve the effect of suppressing the occurrence of abnormal noise and reducing the amount of wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

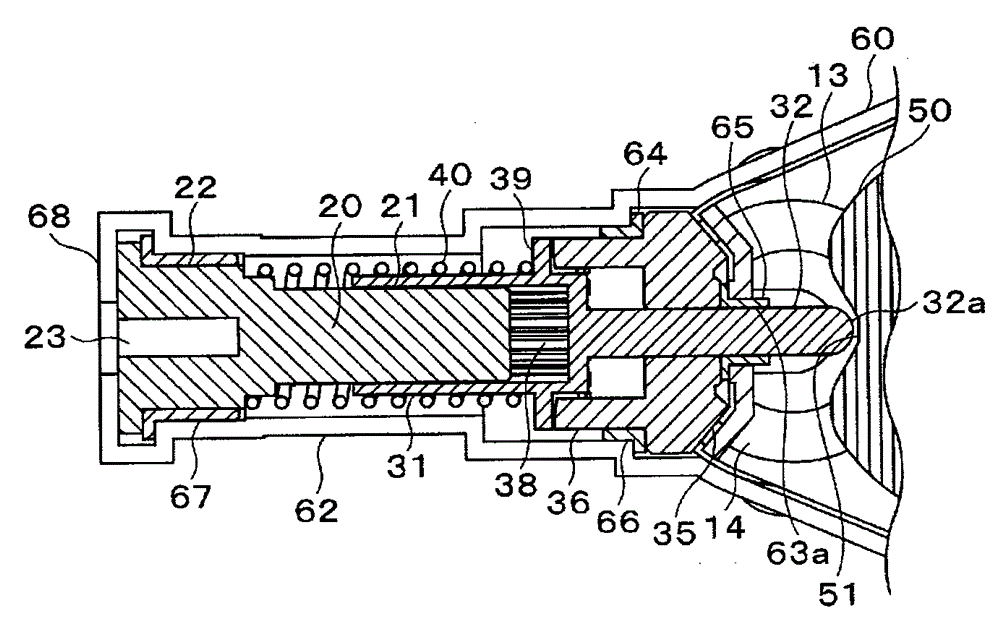

[0088] Next, pass Figure 10 and Figure 11 A second embodiment of the present invention will be described.

[0089] The multi-axis driving device of the second embodiment differs in that a slide cam (selector member) 70 is used instead of the dial cam 50 of the first embodiment, and the shape of the box is also different corresponding to the slide cam 70 .

[0090] Figure 10 and Figure 11 It is a perspective view and a plan view of the multi-axis drive device concerning 2nd Embodiment. In these figures, reference numeral 80 is a case fixed to the upper portion of the motor 10, and the opening of the case 80 is covered with a cover not shown. On the side of box 80 (in Figure 11 A plurality of half-cut cylindrical gear holder parts 62 are formed on the side surfaces on both sides in the X direction in the middle. In this case, the gear holder portion 62 is Figure 11 Among them, two are formed on the right side, and one is formed on the left side. In these gear holder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com