Preparation method and application of copper-doped CQD (carbon quantum dot)/bismuth tungstate composite photocatalyst

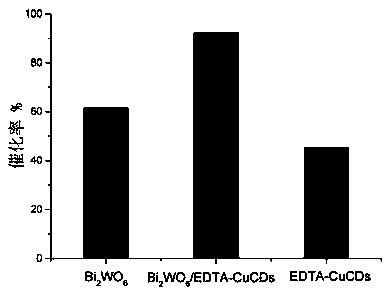

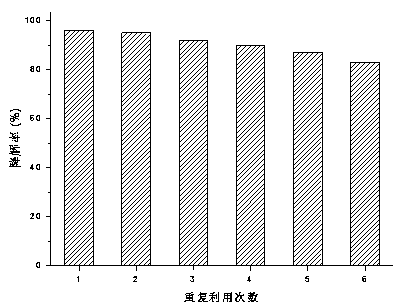

A carbon quantum dot and copper doping technology, applied in the chemical industry, can solve the problems of less research and less research on the photocatalytic performance of carbon quantum dots, and achieve improved degradation rate, good catalytic activity and stability, and electron transfer ability enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The preparation method and application of this copper-doped carbon quantum dot / bismuth tungstate composite photocatalyst are as follows:

[0022] (1) Take 1.6gNa 2 [Cu(EDTA)] and 0.3 g ascorbic acid, mixed evenly, placed in a corundum boat with a lid, and roasted in a high-temperature tube furnace at 300 °C for 2 h, after the roasting was completed, the black product was ground and dissolved in 100 mL of deionized water, and ultrasonicated for 20 min; then the black suspension was centrifuged at 15,000 rpm for 15 min, and the supernatant was passed through a 0.22 μm filter membrane; the filtrate was dried in a vacuum oven at 60 °C for 24 h to obtain copper-doped carbon quantum dots;

[0023] (2) Weigh 7.6g Bi (NO 3 ) 3 ·5H 2 O and 1.0g copper-doped carbon quantum dots were added to 40mL deionized water, stirred and dissolved; then 0.8mmol L -1 Add 5 mL of phosphotungstic acid hydrate to the above solution, and mix ultrasonically for 20 min; after agin...

Embodiment 2

[0027] Embodiment 2: The preparation method and application of this copper-doped carbon quantum dot / bismuth tungstate composite photocatalyst are as follows:

[0028] (1) Take 2.0g Na 2 [Cu(EDTA)] and 0.2g ascorbic acid, mixed evenly, placed in a corundum boat with a lid, and roasted in a high-temperature tube furnace at 300°C for 2h, after the roasting was completed, the black product was ground and dissolved in 100 mL of deionized water, and sonicated for 25 min; then the black suspension was centrifuged at 12,000 rpm for 18 min, and the supernatant was passed through a 0.22 μm filter membrane. The filtrate was taken and dried in a vacuum oven at 65 °C for 24 h to obtain copper-doped carbon quantum dots;

[0029] (2) Weigh 8.0g Bi (NO 3 ) 3 ·5H 2 O and 0.5g copper-doped carbon quantum dots were added to 50mL deionized water, stirred and dissolved; then 0.85mmol L -1 Add 5 mL of phosphotungstic acid hydrate to the above solution, and mix ultrasonically for 25 minutes; af...

Embodiment 3

[0032] Embodiment 3: The preparation method and application of this copper-doped carbon quantum dot / bismuth tungstate composite photocatalyst are as follows:

[0033] (1) Take: 1.8g Na 2 [Cu(EDTA)] and 0.1g ascorbic acid were mixed evenly, placed in a corundum boat with a lid, and roasted in a high-temperature tube furnace at 300°C for 2.5h. After the roasting was completed, the black product was ground and dissolved in 100 mL to Then, the black suspension was centrifuged at 10,000 rpm for 20 min, and the supernatant was passed through a 0.22 μm filter membrane; the filtrate was dried in a vacuum oven at 60 °C for 24 h to obtain copper-doped carbon quantum dots;

[0034] (2) Weigh 7.8g Bi (NO 3 ) 3 ·5H 2 O and 0.8g copper-doped carbon quantum dots were added to 45mL deionized water, stirred and dissolved; then 0.9mmol L -1 Add 5 mL of phosphotungstic acid hydrate to the above solution, and mix ultrasonically for 30 minutes; after aging the solution for 2.5 hours at room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com