Circulating type cement clinker crushing device

A cement clinker and crushing device technology, applied in the direction of grain processing, etc., can solve the problems of difficult control of dust, large space occupation, complex overall structure, etc., and achieve the effect of avoiding large beating and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

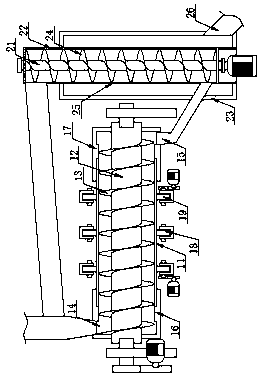

[0015] refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the present invention.

[0016] Such as figure 1 As shown, a circulating cement clinker crushing device includes a block crushing sleeve 11 and a block crushing screw 12 coaxially arranged in the block crushing sleeve 11, and the block crushing screw 12 is provided with There is a spiral crushing blade 13, the outer diameter of the spiral crushing blade 13 is equal to the inner diameter of the block crushing sleeve 11, the axis of the block crushing sleeve 11 is arranged horizontally, and the axial direction of the block crushing sleeve 11 The two ends are respectively provided with an inlet 14 for the block material to be broken and an outlet 15 for the broken block material; it also includes a vertical conveying screw 21 coaxially set from the inside to the outside, an inner sleeve 22 for separating and conveying, and an outer sleeve 23 for separating particles. The axis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com