An online maintenance method for the feed adjustment device of a seamless steel pipe cold rolling mill

A technology for adjusting devices and seamless steel pipes, which is applied in the direction of metal rolling, metal rolling, and keeping roll equipment in an effective state. It can solve the problems of large maintenance resource consumption, reduce operating hours, compact station layout, The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

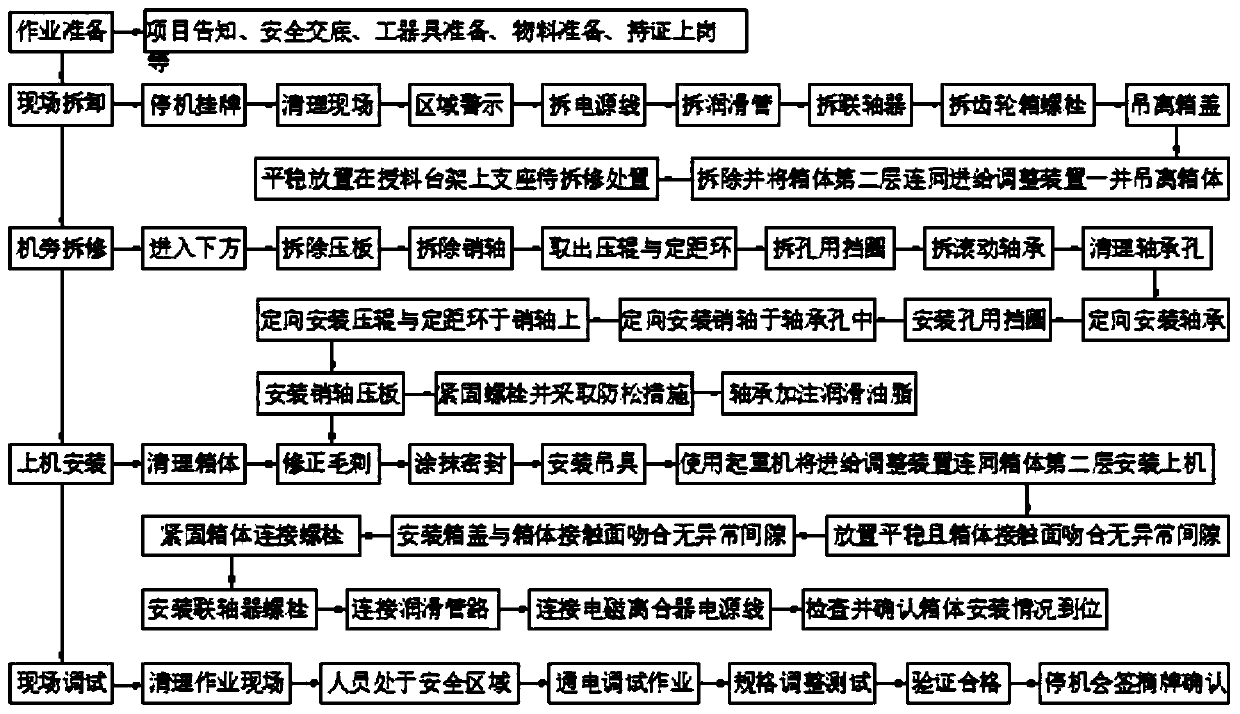

[0037] Taking the LG-220H cold rolling mill as an example, the online maintenance process of the feed adjustment device is:

[0038] S1. Operation preparation: including notification of on-site operation content (operation order form for maintenance project), disclosure of safety technology and implementation of risk prevention measures (on-site tripartite confirmation form, maintenance ticket, power failure sign, maintenance sign, etc.), tools (including slings) , routine maintenance tools, etc.) preparations, qualification certificates for special operations personnel (electricians, finger lifters, etc.), related parts (22313 rolling bearings, pins, pressure rollers, spacer rings) and cleaning and correction of burrs , pre-assembled, etc.

[0039] S2. On-site overhaul: shutdown, positioning, power off, listing → preparation for entering the site (cleaning up the work site) → setting warning lines → removing the fast feed motor and its power cord → removing the side (lateral)...

Embodiment ( 2

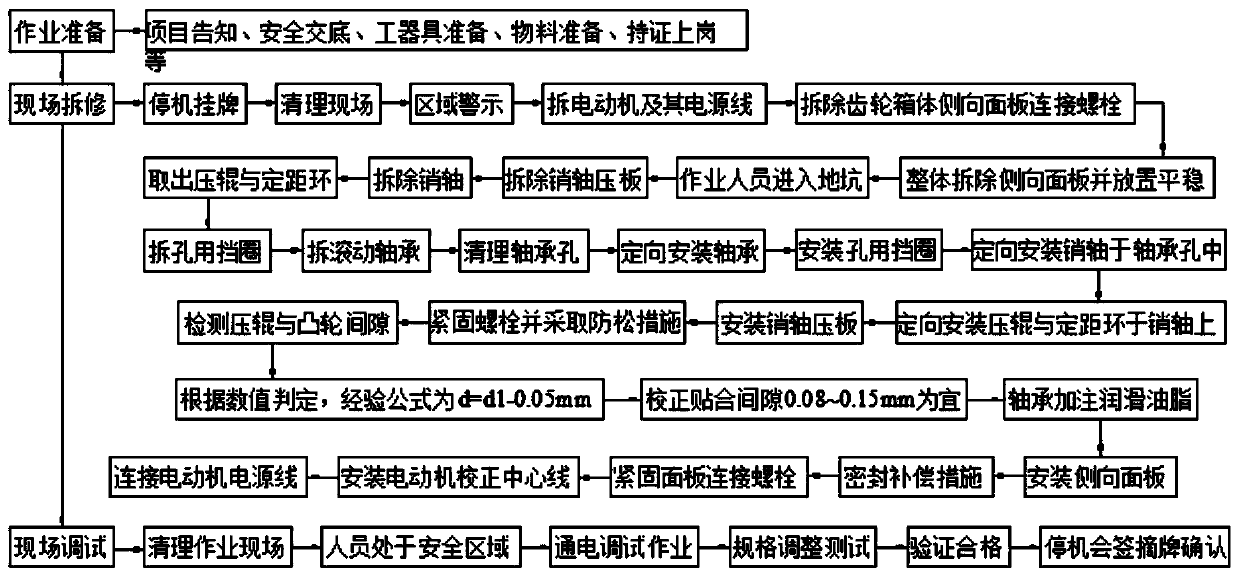

[0042] Taking the LG-150H cold rolling mill as an example, the online maintenance process of the feed adjustment device is as follows:

[0043] S1. Operation preparation: including notification of on-site operation content (operation order form for maintenance project), disclosure of safety technology and implementation of risk prevention measures (on-site tripartite confirmation form, maintenance ticket, power failure sign, maintenance sign, etc.), tools (including slings) , routine maintenance tools, etc.) preparations, qualification certificates for special operations personnel (electricians, finger lifters, etc.), related parts (22312 rolling bearings, pins, pressure rollers, spacer rings) and cleaning and correction of burrs , pre-assembled, etc.

[0044] S2. On-site overhaul: shutdown, positioning, power off, listing → preparation for entering the site (cleaning up the work site) → setting warning lines → removing the fast feed motor and its power cord → removing the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com