Wood cutting equipment used for wood papermaking

A technology of wood and wood, which is applied in the field of wood cutting equipment for wood and papermaking, and can solve problems such as a lot of effort and easy hand injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

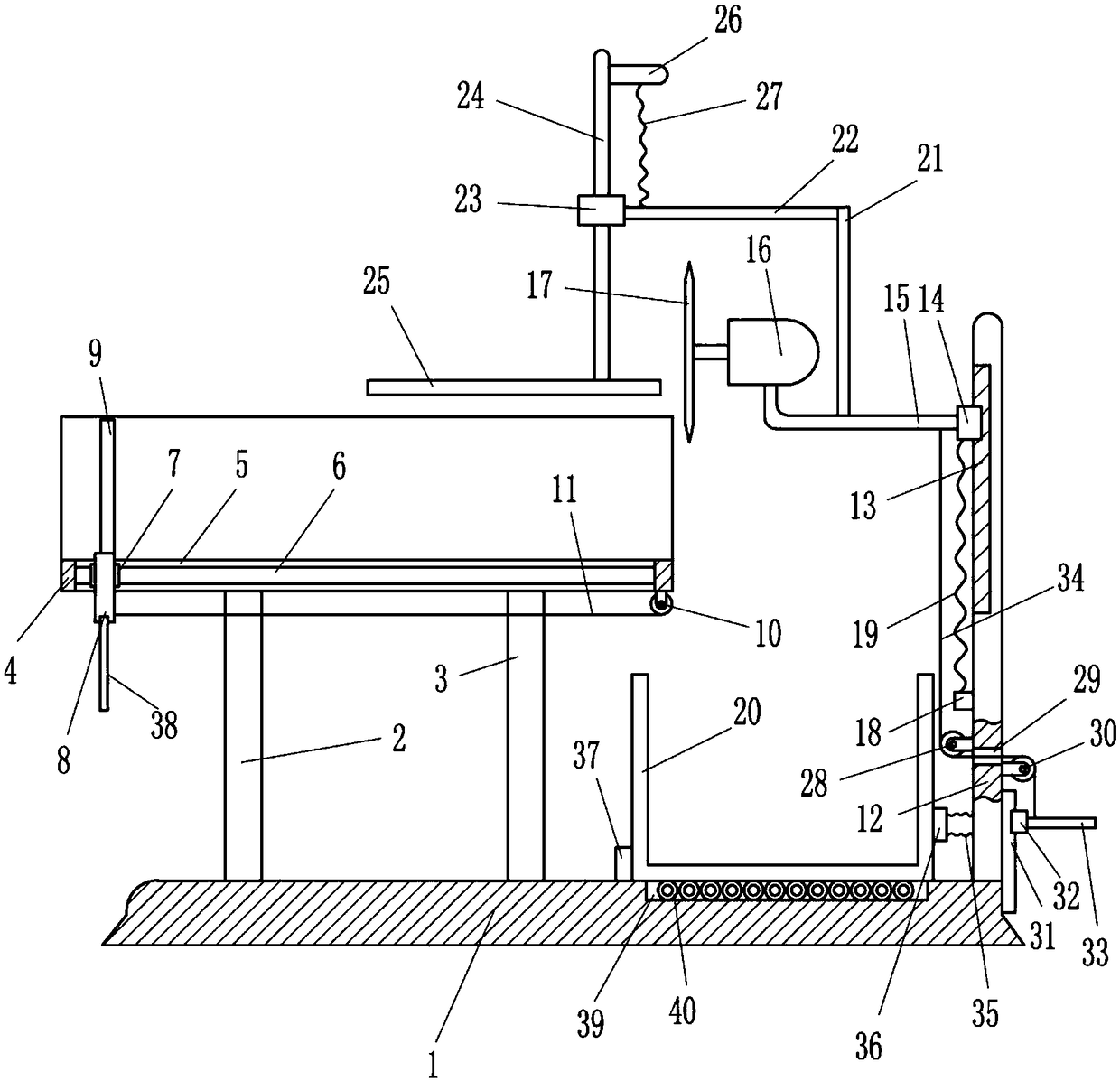

[0020] A wood cutting equipment for wood papermaking, such as figure 1 As shown, it includes a base 1, a first pole 2, a second pole 3, a frame body 4, a first slide rail 6, a first slider 7, a connecting plate 8, a push plate 9, an electric reel 10, The first pull wire 11, the bracket 12, the second slide rail 13, the second slider 14, the L-shaped support rod 15, the motor 16, the cutting wheel 17, the first connecting block 18, the first spring 19 and the collection frame 20, the base 1 The left side of the top is provided with a first pole 2 and a second pole 3, the second pole 3 is on the right side of the first pole 2, the top of the first pole 2 and the second pole 3 is connected with a frame body 4, and the frame There is a word hole 5 in the middle part of the lower wall of the body 4, the first slide rail 6 is installed on the back side of the word hole 5, the first slide block 7 is slidably connected to the first slide rail 6, and the front side of the first slide b...

Embodiment 2

[0022] A wood cutting equipment for wood papermaking, such as figure 1 As shown, it includes a base 1, a first pole 2, a second pole 3, a frame body 4, a first slide rail 6, a first slider 7, a connecting plate 8, a push plate 9, an electric reel 10, The first pull wire 11, the bracket 12, the second slide rail 13, the second slider 14, the L-shaped support rod 15, the motor 16, the cutting wheel 17, the first connecting block 18, the first spring 19 and the collection frame 20, the base 1 The left side of the top is provided with a first pole 2 and a second pole 3, the second pole 3 is on the right side of the first pole 2, the top of the first pole 2 and the second pole 3 is connected with a frame body 4, and the frame There is a word hole 5 in the middle part of the lower wall of the body 4, the first slide rail 6 is installed on the back side of the word hole 5, the first slide block 7 is slidably connected to the first slide rail 6, and the front side of the first slide b...

Embodiment 3

[0025] A wood cutting equipment for wood papermaking, such as figure 1 As shown, it includes a base 1, a first pole 2, a second pole 3, a frame body 4, a first slide rail 6, a first slider 7, a connecting plate 8, a push plate 9, an electric reel 10, The first pull wire 11, the bracket 12, the second slide rail 13, the second slider 14, the L-shaped support rod 15, the motor 16, the cutting wheel 17, the first connecting block 18, the first spring 19 and the collection frame 20, the base 1 The left side of the top is provided with a first pole 2 and a second pole 3, the second pole 3 is on the right side of the first pole 2, the top of the first pole 2 and the second pole 3 is connected with a frame body 4, and the frame There is a word hole 5 in the middle part of the lower wall of the body 4, the first slide rail 6 is installed on the back side of the word hole 5, the first slide block 7 is slidably connected to the first slide rail 6, and the front side of the first slide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com