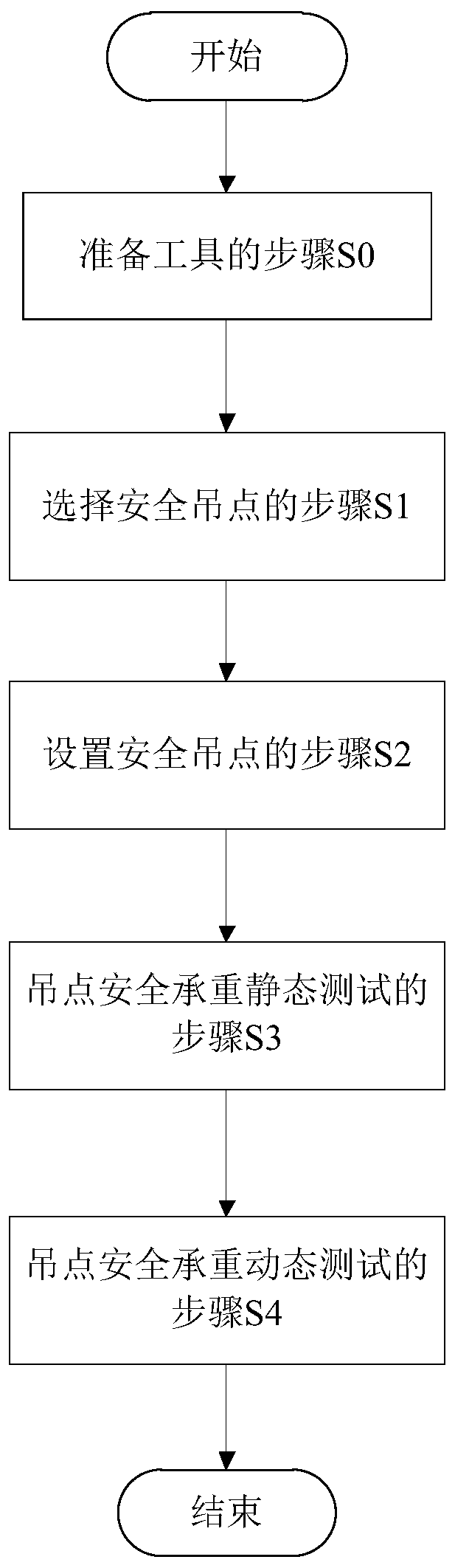

A method for setting the hanging point of a boiler maintenance platform

A technology for overhauling platforms and boilers, applied in the direction of hoisting devices, etc., can solve the problems that the boiler overhaul platform cannot effectively cover the working face, the load-bearing capacity of the lifting point is not up to standard, and the working face overhaul cannot be achieved, so as to eliminate adverse effects and avoid high altitudes. The effect of falling and avoiding secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

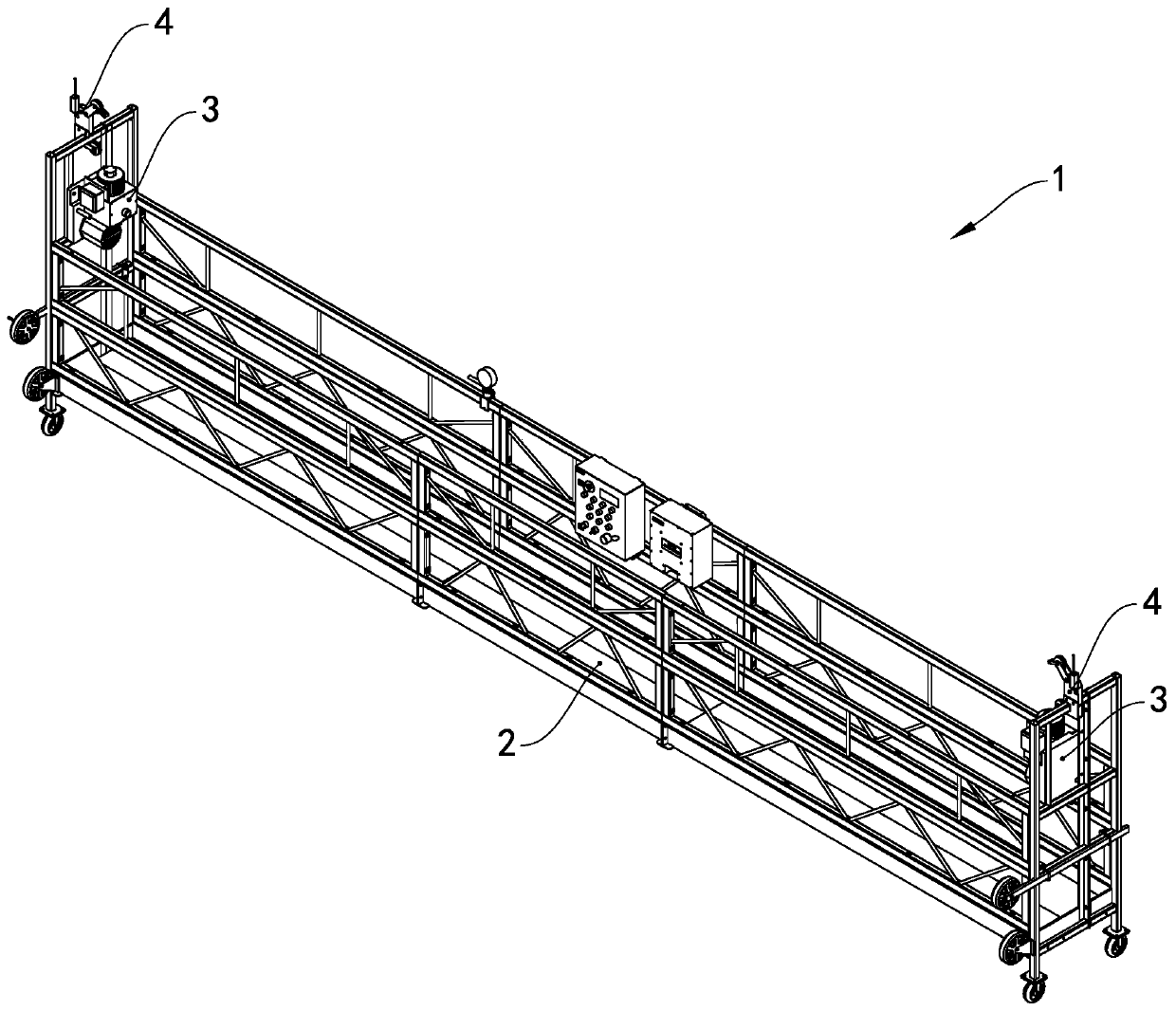

[0023] see figure 1 , the boiler maintenance platform 1 of this embodiment is suspended on the load-bearing beam by a steel wire rope and a sling. Two hoists 3 and two safety locks 4 on the 2. Two hoists 3 are arranged on the left and right sides of the lifting platform 2 respectively, and two safety locks 4 are respectively arranged on the tops of the left and right sides of the lifting platform 2 .

[0024] The hoisting points of the boiler maintenance platform 1 include wire rope hoisting points and personal safety rope hoisting points. The wire rope hoisting points include hoist working wire rope hoisting points and safety lock wire rope hoisting points. Boiler maintenance platform 1 also includes personal safety protection rope, safety belt and anti-fall buckle. The anti-fall buckle is connected with personal safety protection rope and safety belt respectively. Staff can wear safety belt, and personal safety protection rope is connected with personal safety rope lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com