Chain-type manual locking device for blowout preventer and using method thereof

A technology of locking device and well sealing device, which is used in earth-moving drilling, sealing/packing, wellbore/well components, etc. Safe operation and the effect of eliminating personnel fall injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

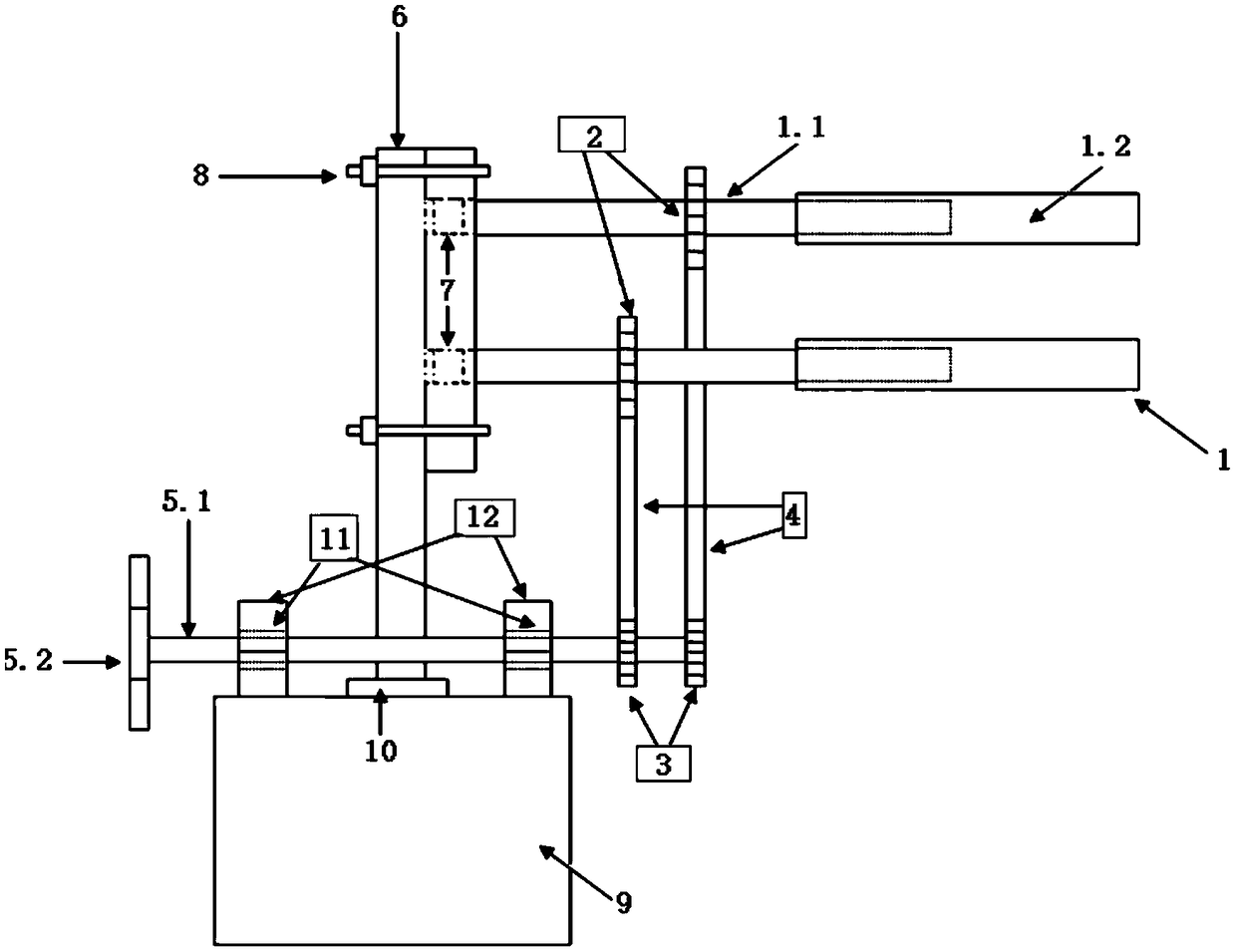

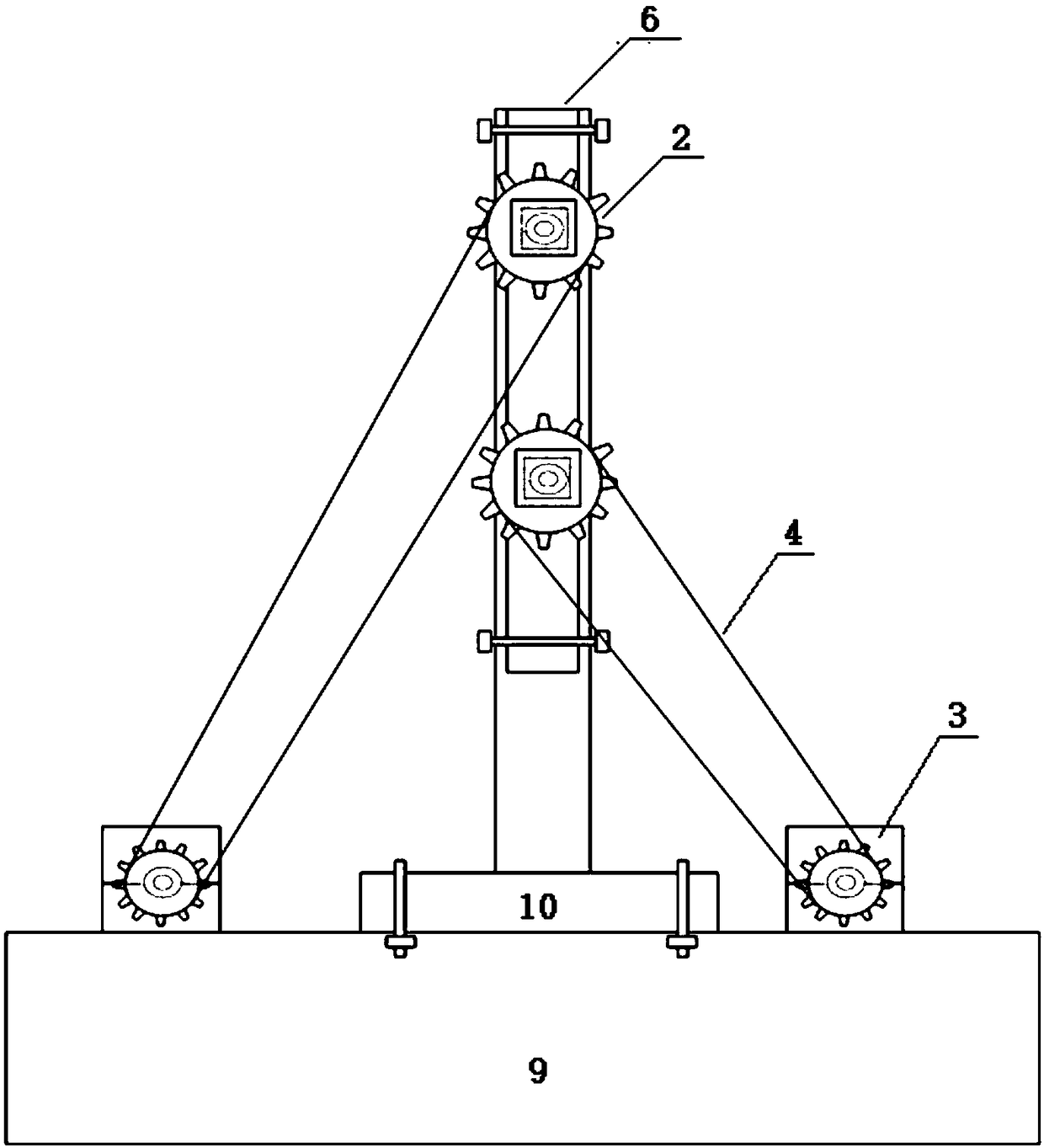

[0030] Such as figure 1 , 2 As shown, a chain type manual locking device of a well plugging device includes at least a drill floor base 9 on which a channel steel 6 is vertically fixed, and a circular manual locking rod is horizontally fixed on the drill floor base 9 5; The upper part of the channel steel 6 is horizontally provided with two square steel manual locking rods 1, the two square steel manual locking rods 1 are arranged in parallel, and the two square steel manual locking rods 1 are both Fixed on the channel steel 6, the other ends of the two square steel manual locking rods 1 are both connected to the locking shaft of the plugging device; a large gear 2 is welded to the two square steel manual locking rods 1 respectively , The circular manual locking lever 5 is welded with two small gears 3, and the two small gears 3 correspond to the large gears 2 on the two square steel manual locking levers 1, and each large gear 2 and the corresponding pinion 3 are connected by ...

Embodiment 2

[0033] On the basis of embodiment 1, the square steel manual locking rod 1 is formed by sleeved connection of a small diameter square steel 1.1 and a large diameter square steel 1.2, and one end of the small diameter square steel 1.1 passes through a fixed bearing 7 and a fixed clip 8 is fixed on the channel steel 6, the other end of the small diameter square steel 1.1 is inserted into the large diameter square steel 1.2, and the other end of the large diameter square steel 1.2 is connected to the locking shaft of the well sealer. The two large gears 2 are respectively welded to two small diameter square steel 1.1 arranged in parallel up and down. The diameter of the small diameter square steel 1.1 is 40 mm, and the diameter of the large diameter square steel 1.2 is 50 mm.

[0034] The circular manual locking rod 5 is composed of a steel pipe 5.1 and a hand wheel 5.2. The hand wheel 5.2 is fixed to one end of the steel pipe 5.1. Two pinions 3 are welded to the other end of the st...

Embodiment 3

[0038] On the basis of the above-mentioned embodiment, this embodiment provides a method for using the chain type manual locking device of the plugging device, which includes the following steps:

[0039] 1) Install one end of the two square steel manual locking rods 1 on the locking shaft of the well sealer, and fix the other end in the fixed bearing 7, and fix the fixed bearing 7 on the channel steel 6 with a fixing clip 8. Steel 6 is fixed on the base 9 of the drill floor;

[0040] 2) Use the bearing 11 and the bearing seat 12 to fix the circular manual locking rod 5 on the base 9 of the drill floor, and use the chain 4 to connect the corresponding large gear 2 and the small gear 3 together;

[0041] 3) Rotate the handwheel 5.2 of the circular manual locking lever 5 to drive its gear and chain, and make the square steel manual locking lever 1 rotate, thereby driving the locking shaft of the sealer to rotate to achieve the sealer lock Or unlock.

[0042] Workers stand on the flat g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com