Diesel vehicle low emission control device and method

A control method and technology of a control device, which are applied to exhaust devices, electronic control of exhaust treatment devices, and diagnostic devices of exhaust treatment devices, etc., can solve problems such as high requirements for chassis layout, high fuel consumption, and deterioration of emissions. , to achieve the effect of reducing the workload of calibration and development, reducing fuel consumption and increasing exhaust temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

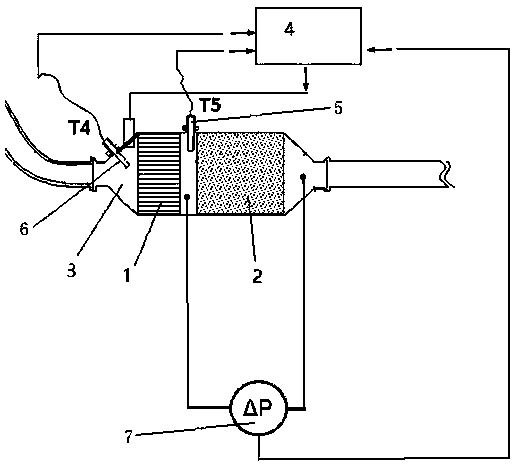

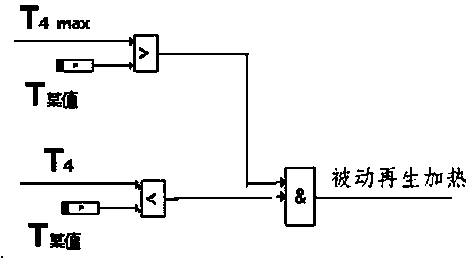

[0058] According to the signals of the exhaust temperature sensors 5, 6 and the differential pressure sensor 7, etc., the electronic control unit 4 (DCU) is input, and the DCU judges whether the engine is in a cold start, whether the selective reduction (SCR) needs auxiliary heating, and whether the PM particles need to be passive. Regeneration, whether the PM particles need to be actively regenerated, so that the DCU controls the electric heating device 3 to conduct electric heating on the exhaust gas.

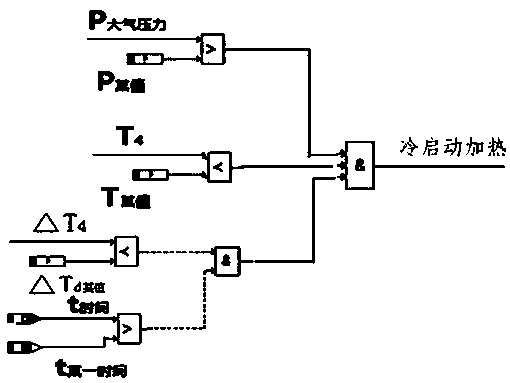

[0059] When the diesel engine is in a cold start state, that is:

[0060] i) The pressure P of the atmosphere 大气 Greater than 0.76 P 大气 ;

[0061] ii) The current temperature T of the oxidation catalyst 1 4 Less than 180°C;

[0062] iii) Over a period of time T 时间 less than 5 seconds, T 4 The change value of △T 4 less than 1°C;

[0063] The electronic control device 4 controls the electric heating device 3 to perform cold start heating according to its own logic or th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com