Extractor hood

A range hood and fan technology, applied in the field of kitchen appliances, can solve the problems of being stuck on the back of the main box, the decoration cover is not fixed firmly, the decoration cover is not completely fixed with the hood box, etc., and it is easy to install and disassemble, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

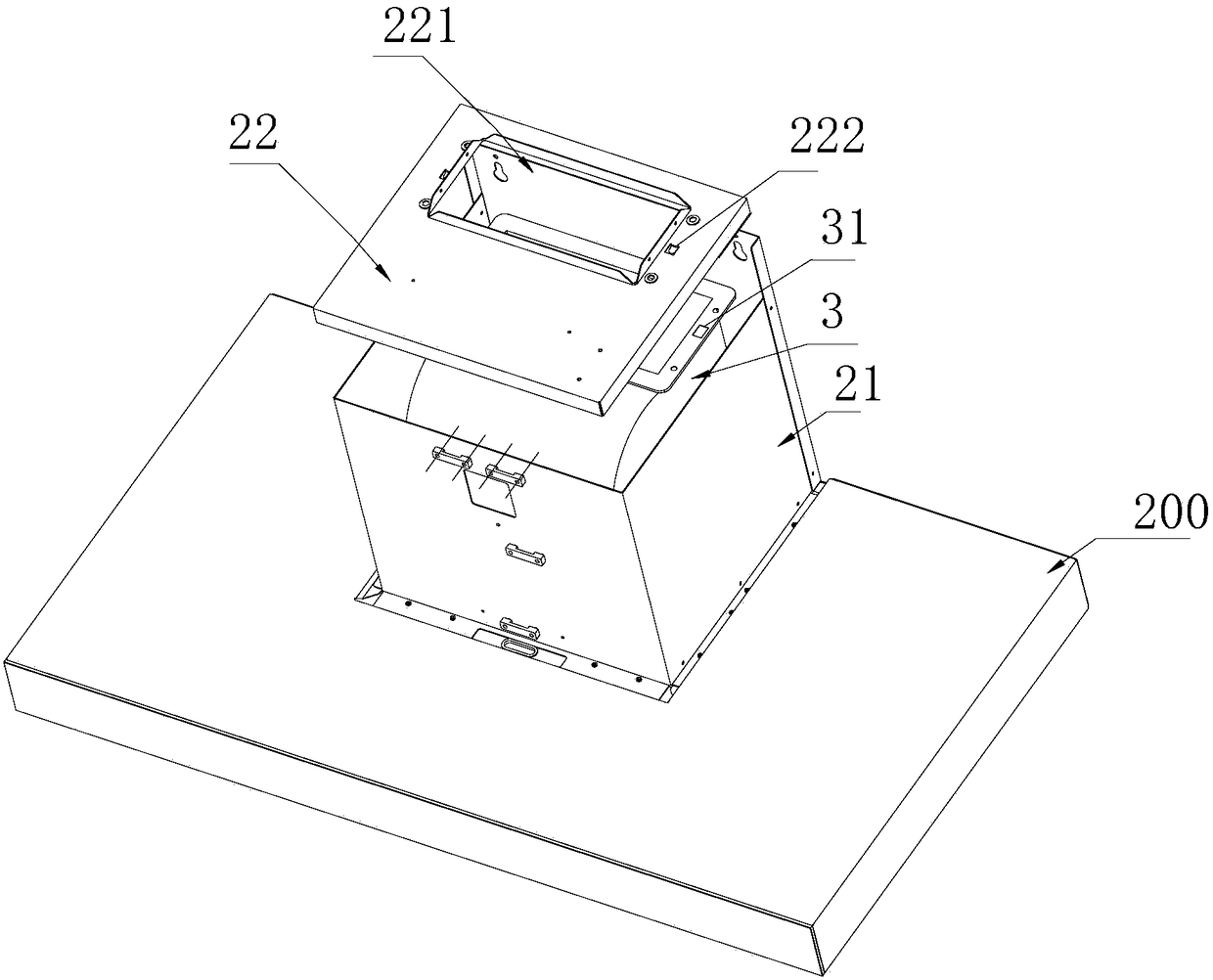

[0048] Such as Figure 1-6As shown, a range hood includes a main box 400 and a fan 3. The fan 3 extends into the inside of the main box 400 from the bottom of the main box 400, and is first positioned with the main box 400 through a pre-positioning structure, and then It is fixed with the main box body 400 by fasteners.

[0049] Preferably, the pre-positioning structure includes a first positioning part 222 provided on the main box 400 and a second positioning part 31 provided on the fan 3, and the second positioning part 31 is fixed on the On the first positioning part 222, the first positioning part 222 restricts the movement of the fan 3 on the horizontal plane.

[0050] Preferably, the main box 400 includes a shroud 21 and a top plate 22 covering the top opening end of the shroud 21, the first positioning part 222 is arranged on the top plate 22, and the fan 3 includes a volute, The second positioning portion 31 is arranged on the end surface of the air outlet of the vol...

Embodiment 2

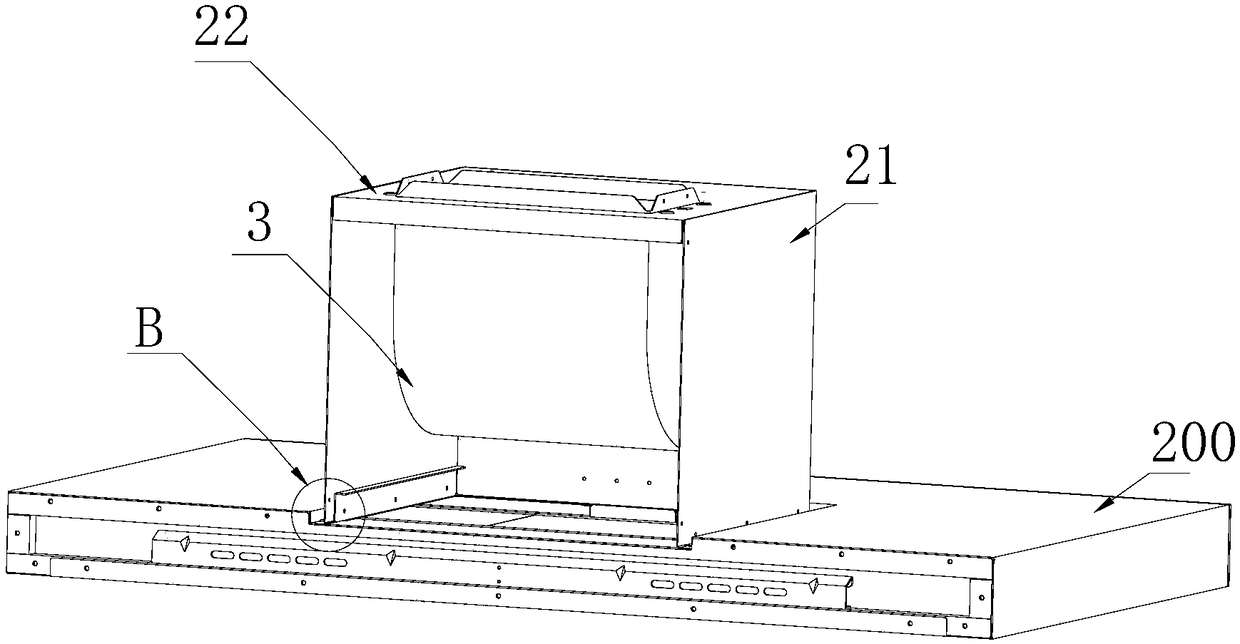

[0059] Such as Figure 1-6 As shown, this embodiment defines the fixing structure of the bottom of the main box 400 on the basis of the first embodiment.

[0060] The range hood also includes a fume collecting hood 200, and the fume collecting hood 200 is provided with a smoke exhaust port for discharging the smoke in the fume collecting hood 200 out of the fume collecting hood 200. The main box 400 It is arranged on the upper part of the smoke collecting hood 200, and its bottom opening communicates with the smoke exhaust port;

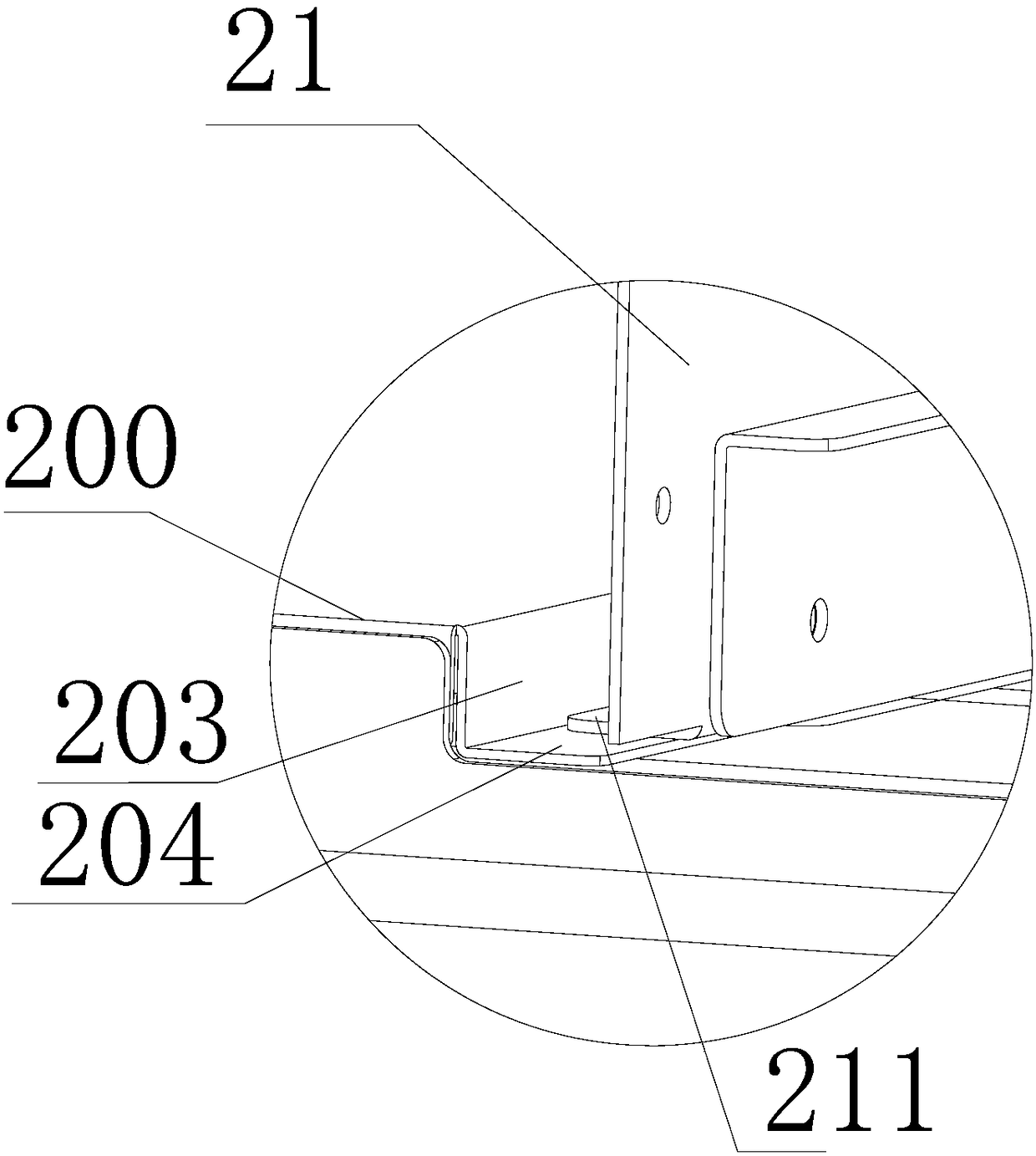

[0061] Preferably, the bottom of the coaming plate 21 is installed on the edge of the smoke outlet through fasteners;

[0062] Preferably, the lower part of the enclosure 21 is provided with a first connection part, the edge of the smoke outlet is provided with a second connection part, and the first connection part and the second connection part are connected by fasteners.

[0063] Preferably, the bottom of the enclosure 21 is provided with a fold...

Embodiment 3

[0075] Such as Figure 7-11 As shown, this embodiment is further limited on the basis of the second embodiment, the range hood includes a fume collecting hood 200, and the fume collecting hood 200 is provided with a smoke collecting hood 200 for discharging the smoke in the fume collecting hood 200 The smoke exhaust port 201, the decorative cover 100 is set on the upper part of the smoke collecting hood 200, and is sleeved on the outside of the main box body 400. The decorative cover 100 is arranged around the smoke exhaust port 201 and is detachably connected to the edge of the smoke exhaust port 201 , The bottom of the smoke outlet 201 is equipped with a filter screen.

[0076] At present, the decorative cover 100 is generally installed on the upper wall of the smoke collecting hood 200, and can be connected with the smoke collecting hood through a buckle structure. During work, the decorative cover 100 is likely to resonate with the smoke collecting hood, which increases t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap