Material surface test sample table with accuracy improvement function

A technology for surface testing and accuracy, which is applied in the direction of material analysis, surface tension analysis, surface/boundary effects, etc. It can solve problems such as sample movement, affecting test accuracy, and affecting liquid droplets, so as to improve accuracy, good fixation, Easy to drip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

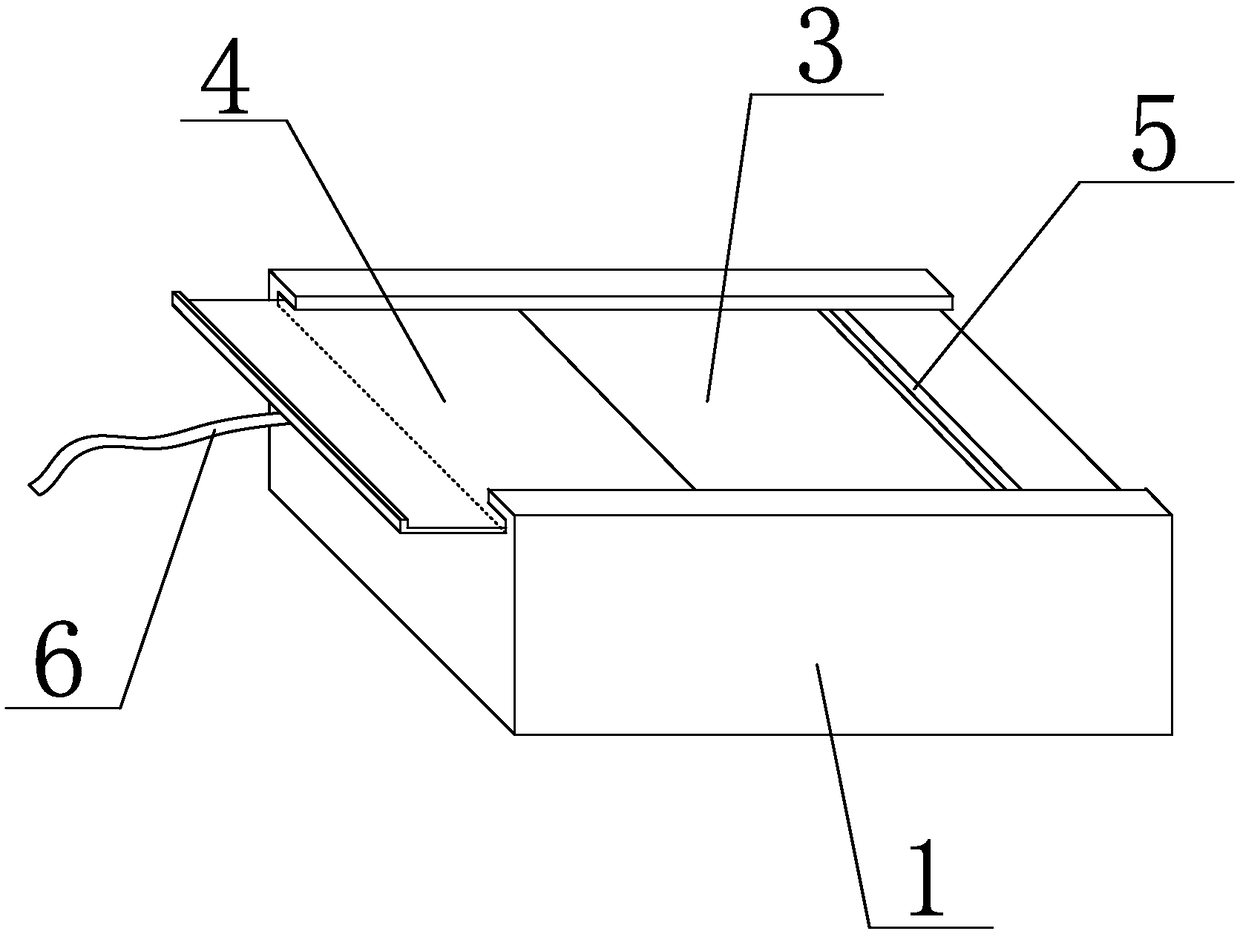

[0021] Such as figure 1 As shown, the material surface testing sample table with improved accuracy of the present invention includes a sample placement table 1, and the surface of the sample placement table 1 is provided with a sample holding slot 3 that runs through the two ends of the sample placement table 1, and the sample holding slot 3 is an inverted T-shaped, the size of the notch of the sample card slot 3 is smaller than the size of the bottom of the slot, the bottom of the sample card slot 3 is provided with a mobile support plate 4, the bottom surface of the mobile support plate 4 and the bottom of the slot are connected with the slider through a chute, The mobile support plate 4 can move back and forth in the horizontal direction along the sample card slot 3, and the bottom of the sample card slot 3 next to the mobile support plate 4 is provided with a limit bar 5 in parallel, and the height of the limit bar 5 matches the height of the bottom of the slot. There is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com