Concrete quality monitoring system

A quality monitoring and concrete technology, applied in the general control system, control/regulation system, closed-circuit television system, etc., can solve the problems of unable to judge the concrete state in real time, unable to feedback the concrete state, unable to timely and accurately monitor the discharge time of the concrete state, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following describes several preferred embodiments of the present invention with reference to the accompanying drawings, so as to make the technical content clearer and easier to understand. The present invention can be embodied in many different forms of embodiments, and the protection scope of the present invention is not limited to the embodiments mentioned herein.

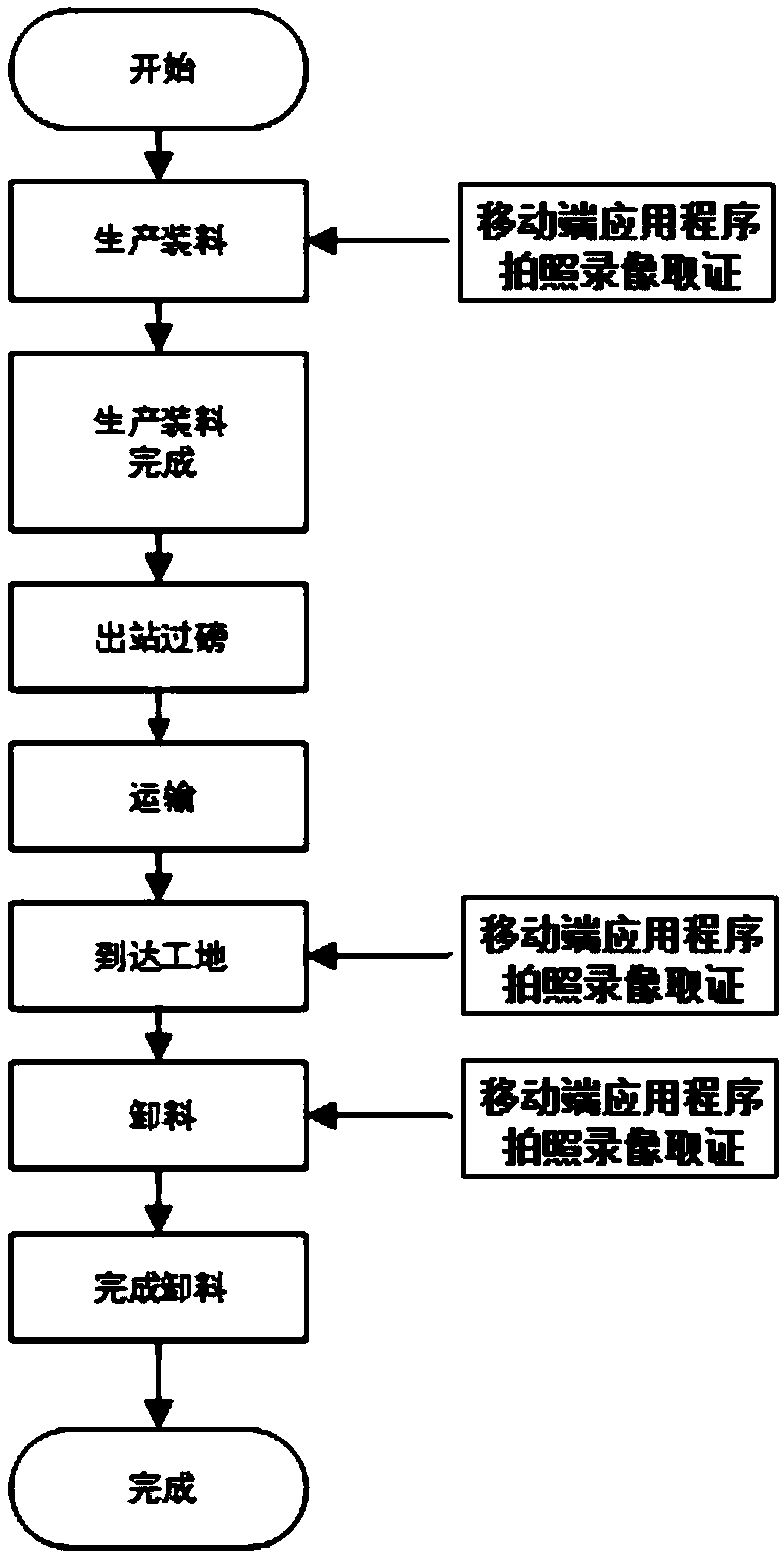

[0017] like figure 1 As shown, in the present invention, when concrete is loaded, arrived at the construction site, and unloaded, the driver takes pictures or takes videos and uploads them through the mobile terminal application.

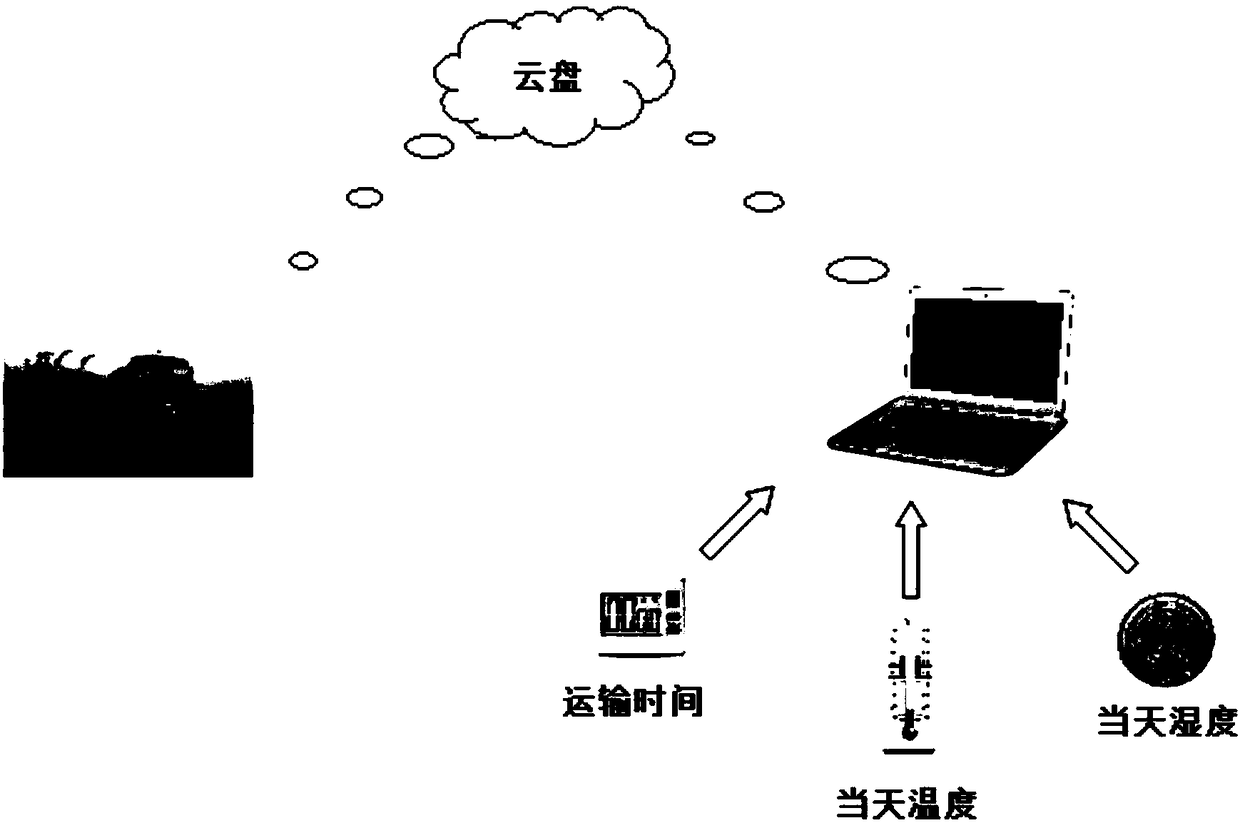

[0018] When loading concrete, the driver uses the mobile app to take photos or take videos and upload them to the cloud disk. The laboratory personnel view the photos or videos through the computer program to monitor the state of the concrete during discharge to ensure the quality of the discharge.

[0019] When the concrete arrives at the construction site after being tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com