Automatically-controlled feeding device

A technology for automatic control and breeding areas, applied in the poultry industry, application, poultry cages or houses, etc., can solve the problems of difficult access to scientific feeding, time-consuming, labor-intensive, etc., to prevent the breeding and spread of germs, reduce The link of feeding to ensure the effect of healthy growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

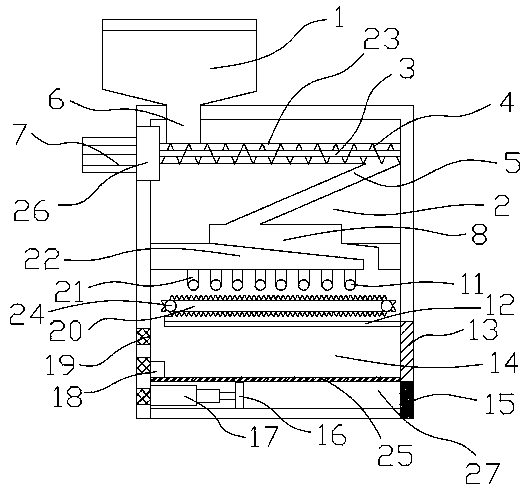

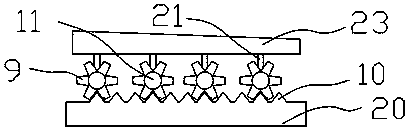

[0018] Such as Figure 1-2 As shown, the feeding device for automatic control includes a box body 2, a feed hopper 1 is arranged on the upper left side of the box body 2, one end of the feed pipe 6 is connected to the bottom of the feed hopper 1, and the other end of the feed pipe 6 is connected to a quantitative device 23. The metering device 23 is located inside the box body 2. The lower right side of the metering device 23 is connected to the feeding inclined pipe 5, and the discharge end of the feeding inclined pipe 5 is connected to the milling device. There is a breeding area 14 below the milling device. The breeding area 14 below is provided with defecation area 27. This device has a simple structure and is very practical. It reduces the link of feeding and feeding, reduces the labor intensity of laborers, and realizes scientific feeding. It is suitable for most poultry breeding, collecting and storing materials, grinding, feeding, breeding, and defecation. The integra...

Embodiment 2

[0027] Such as Figure 1-2As shown, the automatic control feeding device works as follows: put the feed into the feed hopper 1, the feed falls from the feed hopper 1 into the metering device 23, and the dropped feed will follow the rotation of the rotating shaft 3 to Push forward until the end of the metering device 23 is pushed down to the grinding device for grinding, the conveyor belt 20 pushes the feed forward while grinding, and pours the ground feed into the collection tank 19 Among them, poultry can be stocked in the breeding area 14, and the feces discharged by the poultry will fall to the lower floor through the filter screen 25, and the cylinder 17 of the lower floor will push the push plate 16 forward, and the feces can be discharged from the defecation port 15, ensuring the hygiene of the breeding area situation.

[0028] The conventional technologies in the foregoing embodiments 1 and 2 are prior art known to those skilled in the art, so details will not be repea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com