Microfluidic substrate, driving method thereof and miniaturized total analysis system

A microfluidic and substrate technology, applied in the field of micro-total analysis systems, can solve the problems of large size occupied area and limitation of switching transistors, and achieve the effect of high resolution and resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

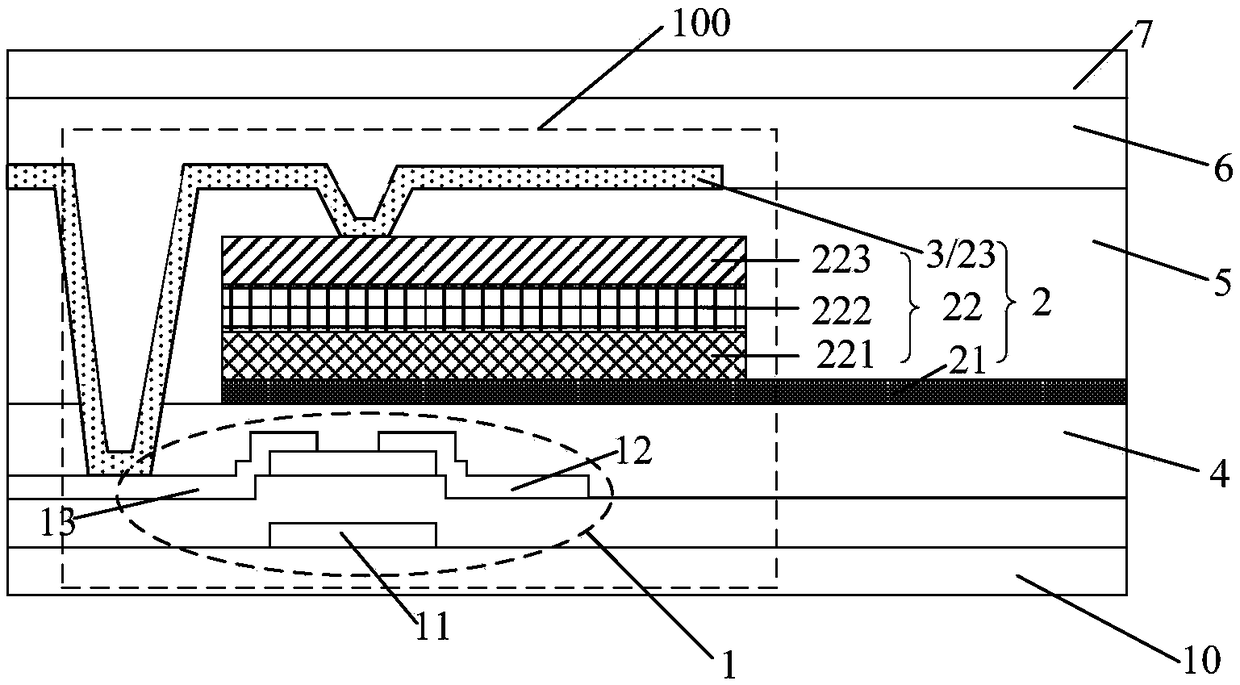

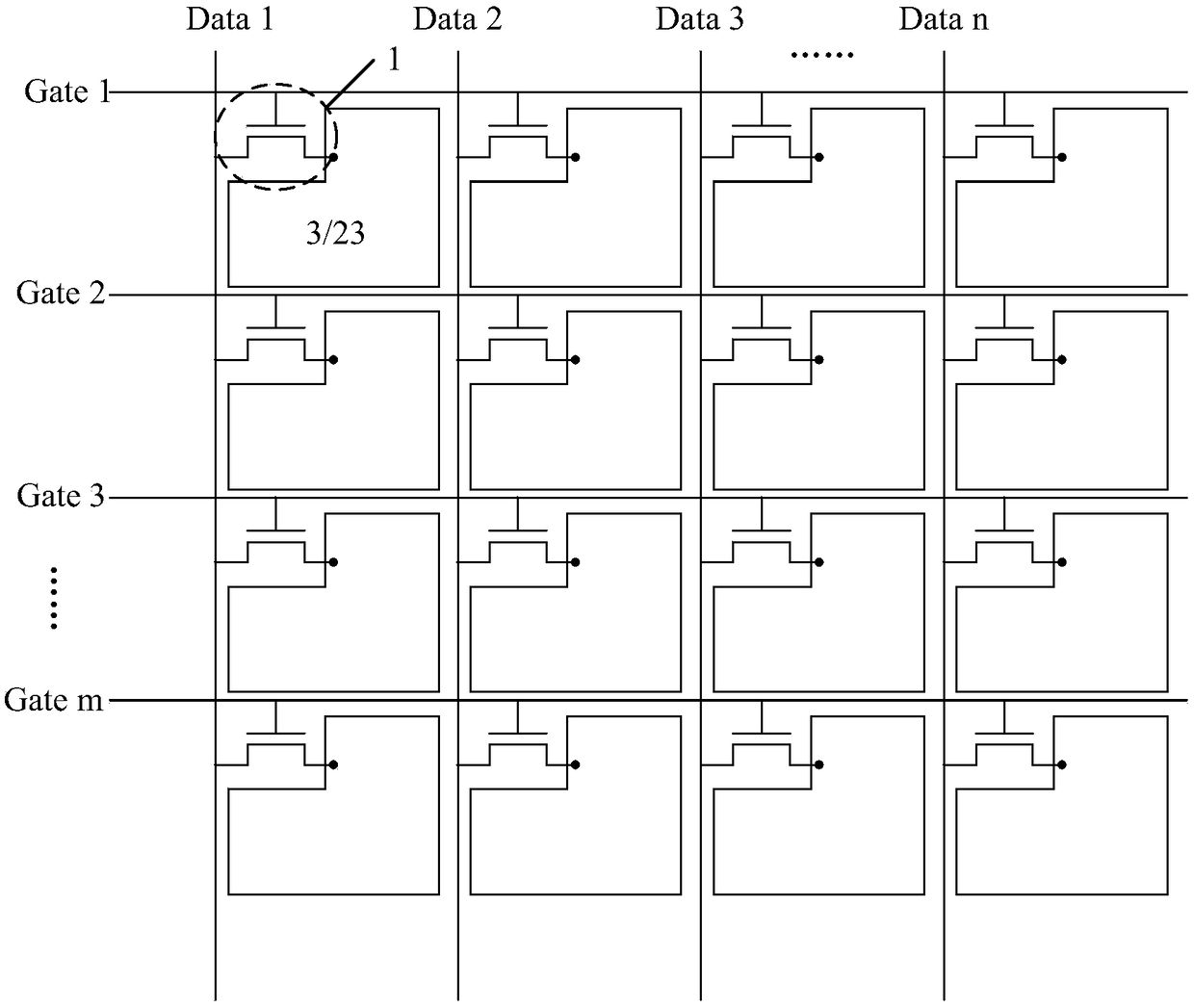

[0051] This embodiment provides a microfluidic substrate, including: a base, a plurality of detection modules located on the base; each detection module includes: a switch unit, a drive electrode, and a photosensitive unit located on the base; wherein, the drive electrodes are connected to the switch unit The signal output end of the photosensitive unit, and one of the first pole and the second pole of the photosensitive unit is also connected to the signal output end of the switch unit.

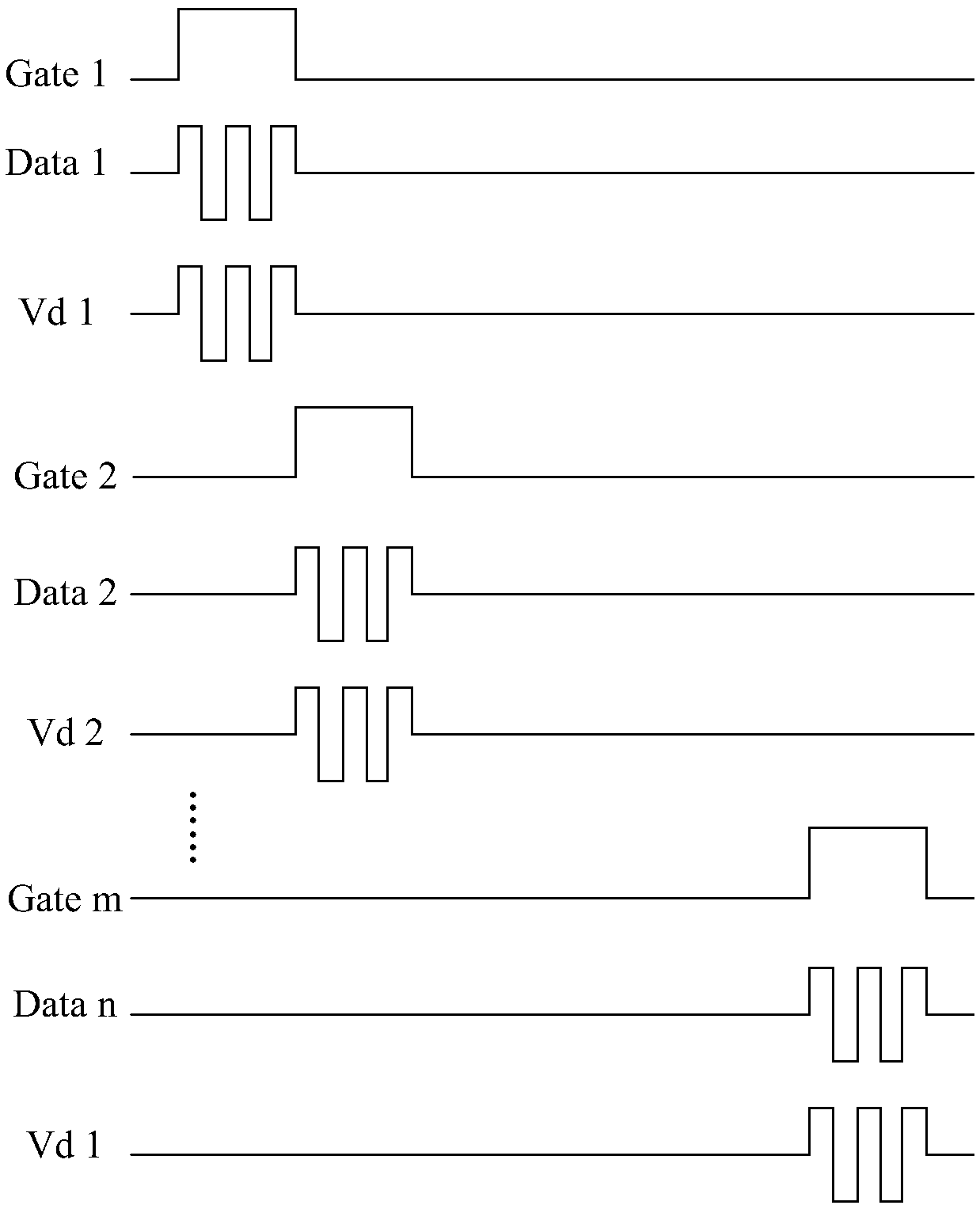

[0052]Since in the microfluidic substrate of this embodiment, the driving electrodes and photosensitive units in each detection module are connected to the same switch unit, therefore, applying the microfluidic substrate to the micro-total analysis system can be performed in the droplet driving stage. , control the switch unit to open, and input the first voltage to the signal receiving end of the switch unit, and transmit it to the driving electrode, then control the switch unit to close, an...

Embodiment 2

[0069] combine Figure 5 As shown, this embodiment provides a micro-total analysis system, which includes the microfluidic substrate in Example 1. Therefore, the micro-total analysis system in this embodiment can achieve high-resolution design.

[0070] Of course, the micro-total analysis system in this embodiment also includes an optical unit 8 configured to form light irradiated to the driving electrodes 3 . Wherein, the optical unit 8 includes: a light source 81 and an optical waveguide layer 82; specifically, the light source 81 is arranged on the side of the optical waveguide layer 92, and can output multiple paths of light with different wavelengths; the optical waveguide layer 82 and the microfluidic The control board is relatively set.

[0071] Wherein, during droplet driving and droplet detection, the droplet is located between the microfluidic substrate and the optical unit 8, as Figure 5 shown. Specifically, the movement of the driven droplet is realized by cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com