Baffle device achieving automatic locking

A baffle device, automatic technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of leg injury, difficulty in wearing exoskeleton products, etc., and achieve the effect of simple switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

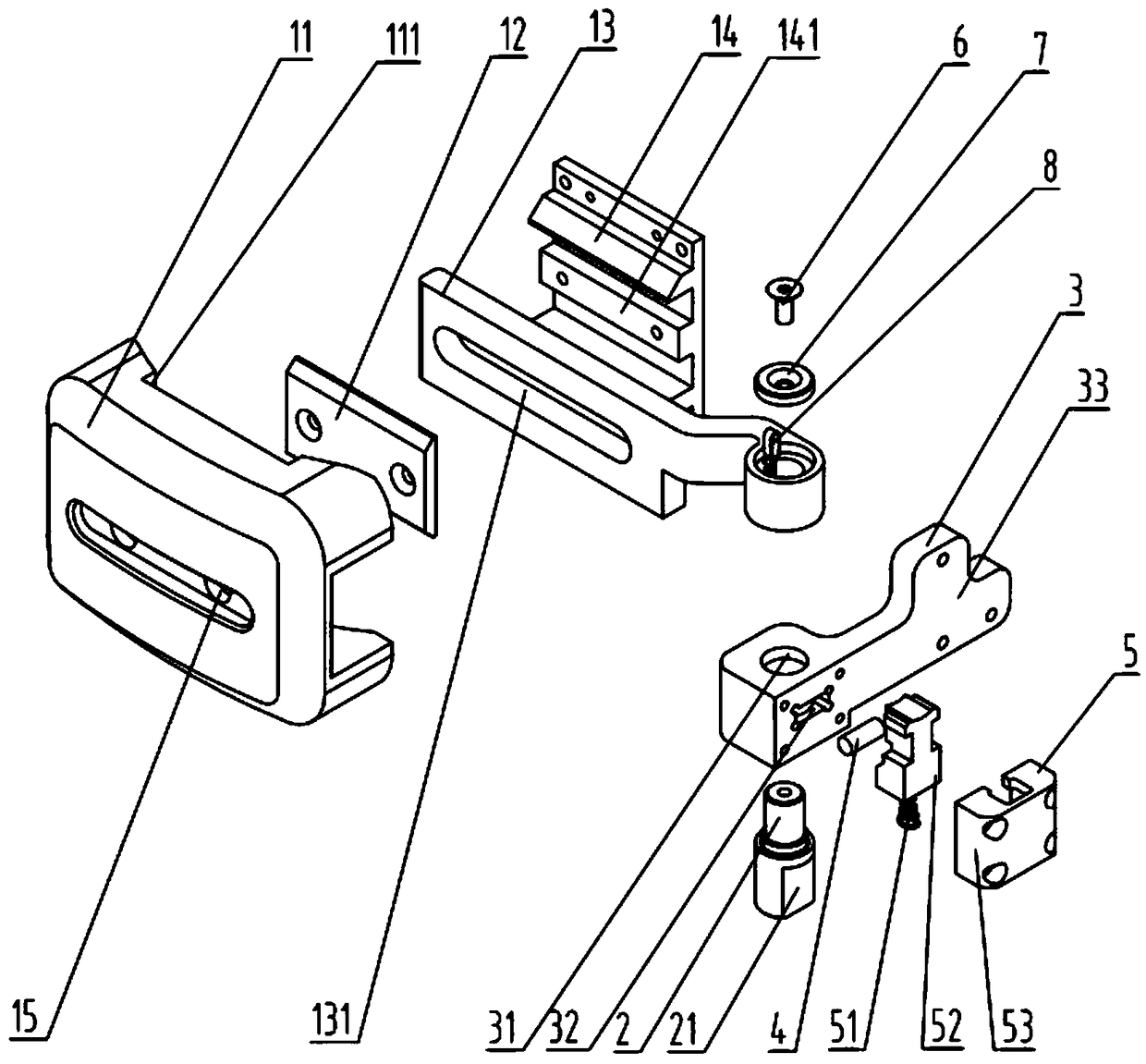

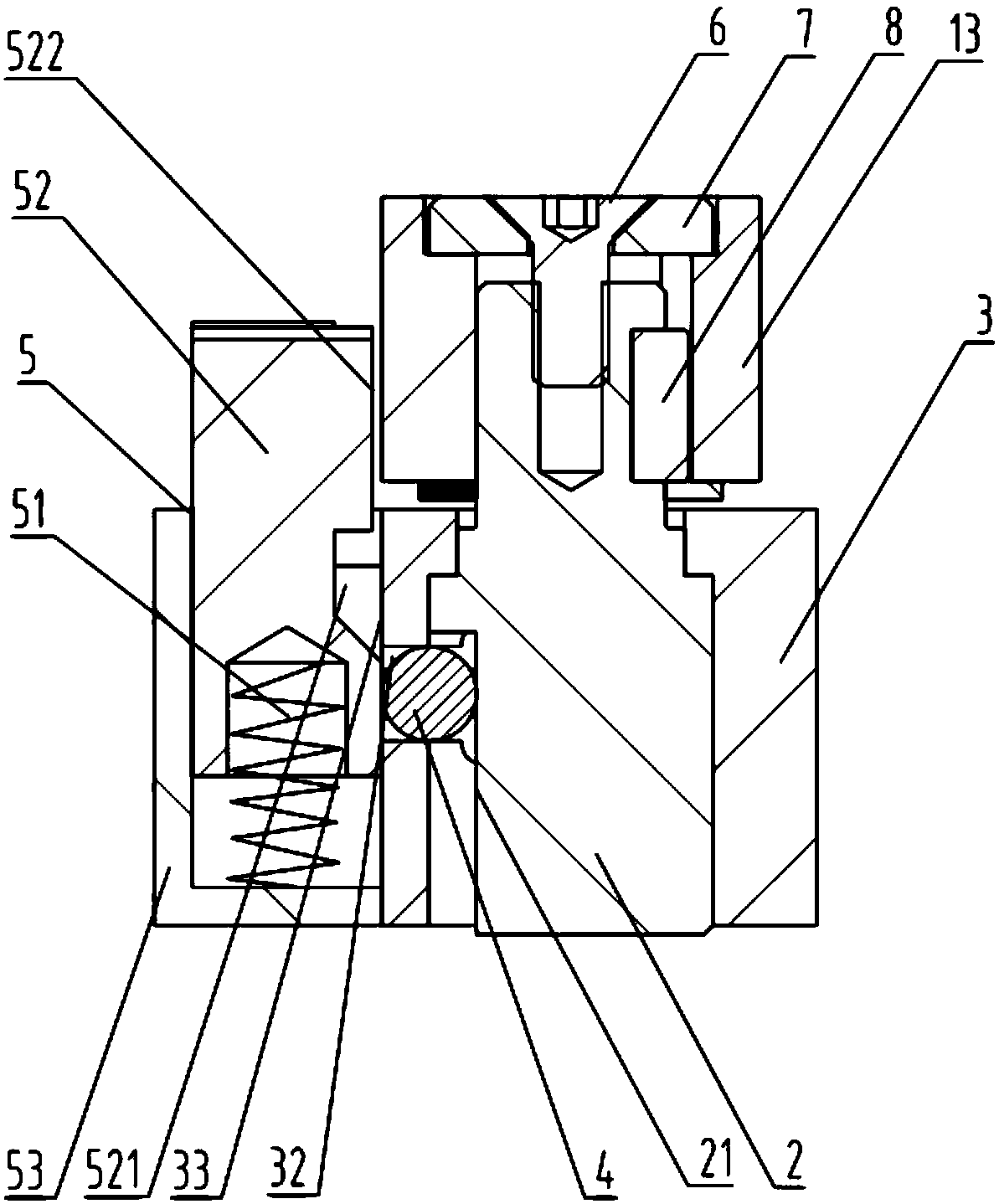

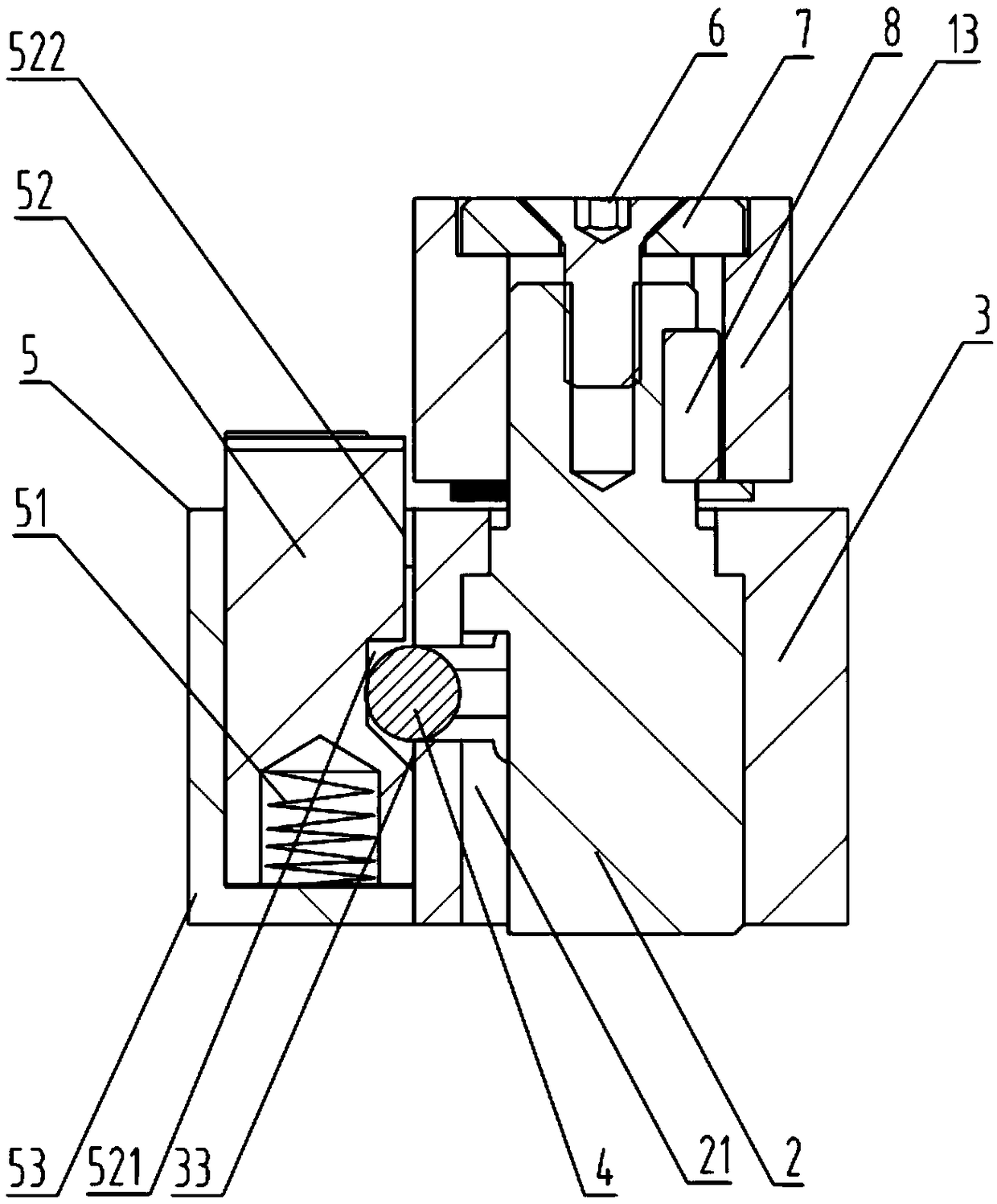

[0031] Such as Figure 1-5 As shown, it is an embodiment of a self-locking baffle device of the present invention, including a baffle 1, a rotating shaft 2, a fixing frame 3, a locking member 4 and a manipulation part 5; the fixing frame 3 is fixed on the exoskeleton robot At a designated position, a shaft hole 31 corresponding to the shaft 2 is opened on the fixed frame 3, and the shaft 2 passes through the shaft hole 31 and is fixedly connected with the baffle plate 1; There is a locking hole 32 vertically intersecting the shaft hole 31, corresponding to the position of the locking hole 32, a locking groove 21 is opened on the shaft 2; the operating part 5 includes an elastic part 51 and a The pressing block 52 at the free end of the elastic member 51; corresponding to the position of the locking hole 32, the pressing block 52 is provided with a groove 521 or a protrusion, the locking hole 32, the locking groove 21, The shape of the groove 521 matches the shape of the locki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com