High-voltage incoming cabinet with self-locking function and working method of high-voltage incoming cabinet

A technology for high-voltage incoming lines and incoming cabinets, which is applied in the direction of pull-out switchgear, switchgear, electrical components, etc., which can solve problems such as personal injury and easy accidental touch by operators, so as to prevent loss of position, improve safety, Guaranteed coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

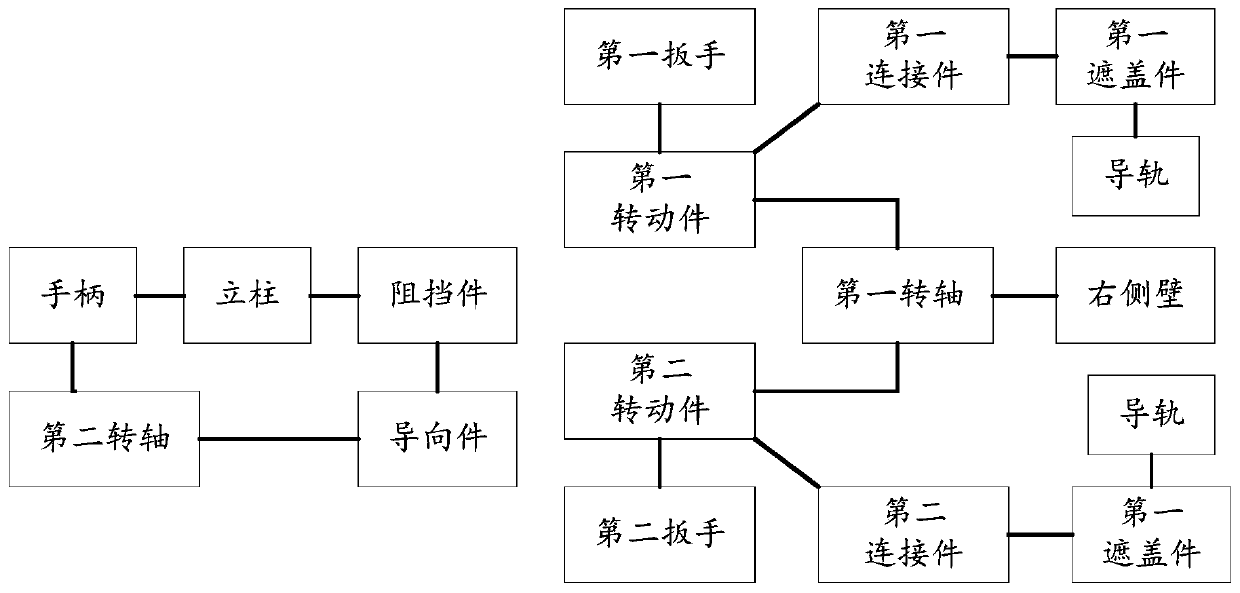

[0036] figure 1 Schematically gives a simplified structural diagram of the high-voltage incoming line cabinet with self-locking function according to the embodiment of the present invention, as shown in figure 1 As shown, the high-voltage incoming line cabinet includes:

[0037] a circuit breaker chamber having a rear side wall, a left side wall, and a right side wall;

[0038] a first contact group and a second contact group, the second contact group and the first contact group are arranged on the rear side wall from top to bottom;

[0039] The first cover and the second cover are rectangular sheet structures, the first cover is used to cover the first contact group, and the left and right sides of the first cover are respectively arranged on the guide rail; The second cover is used to cover the second contact group, and the left and right sides of the second cover are respectively arranged on the guide rail; the first cover and the second cover move up and down on the guid...

Embodiment 2

[0068] An application example of a high-voltage incoming cabinet with a self-locking function according to an embodiment of the present invention.

[0069] In this application example, in the vertical direction, the first wrench, the handle and the second wrench are set up and down in sequence; a guide is set to convert the rotation of the handle into the back and forth movement of the blocking piece. When the handle is pushed by an external force such as a handcart, The stopper is out of position to realize the automatic opening function; under the action of the withdrawal of the handcart and the spring, the stopper returns to the position to realize the automatic locking function; the left and right sides of the first cover and the second cover have connecting parts , the cylindrical guide rail passes through the connecting part to realize the up and down movement of the covering part, and the section of the connecting part on the horizontal plane is "]" shaped; the first rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com