Spray coating robot nozzle for high-viscosity ink

A spraying robot and high-viscosity technology, which is applied in coating devices, additive processing, etc., can solve problems such as insufficient nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The content of the present invention will be further described below in conjunction with the accompanying drawings and preferred specific embodiments of the present invention. The examples given are only for explaining the present invention, not for limiting the scope of the present invention.

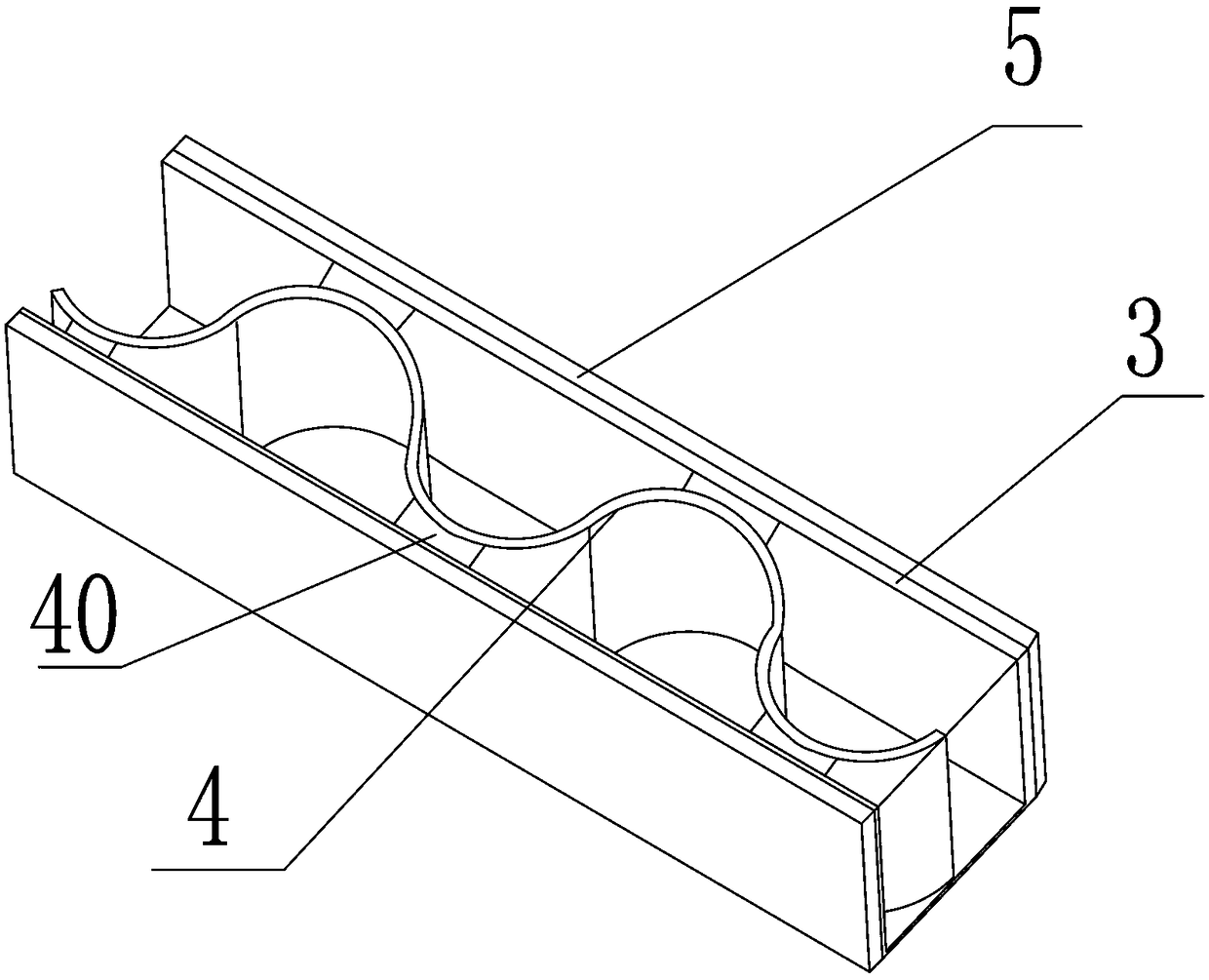

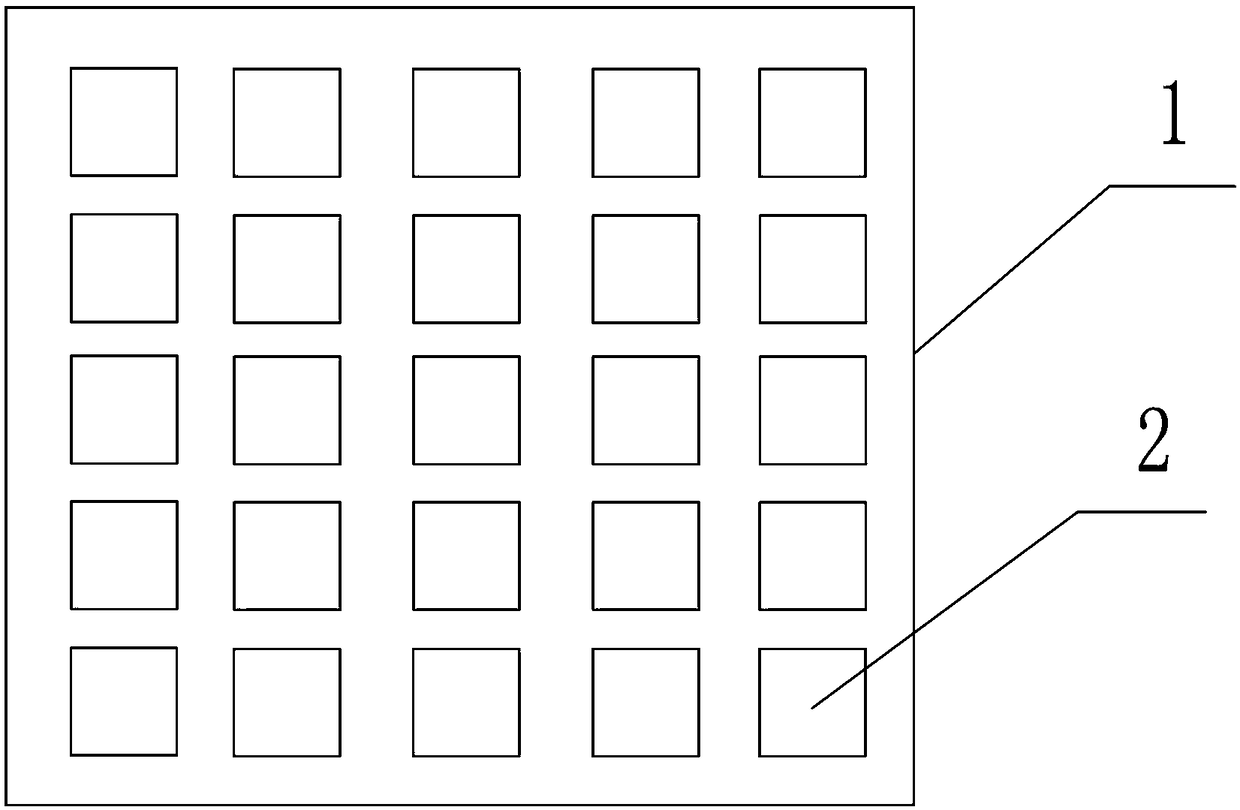

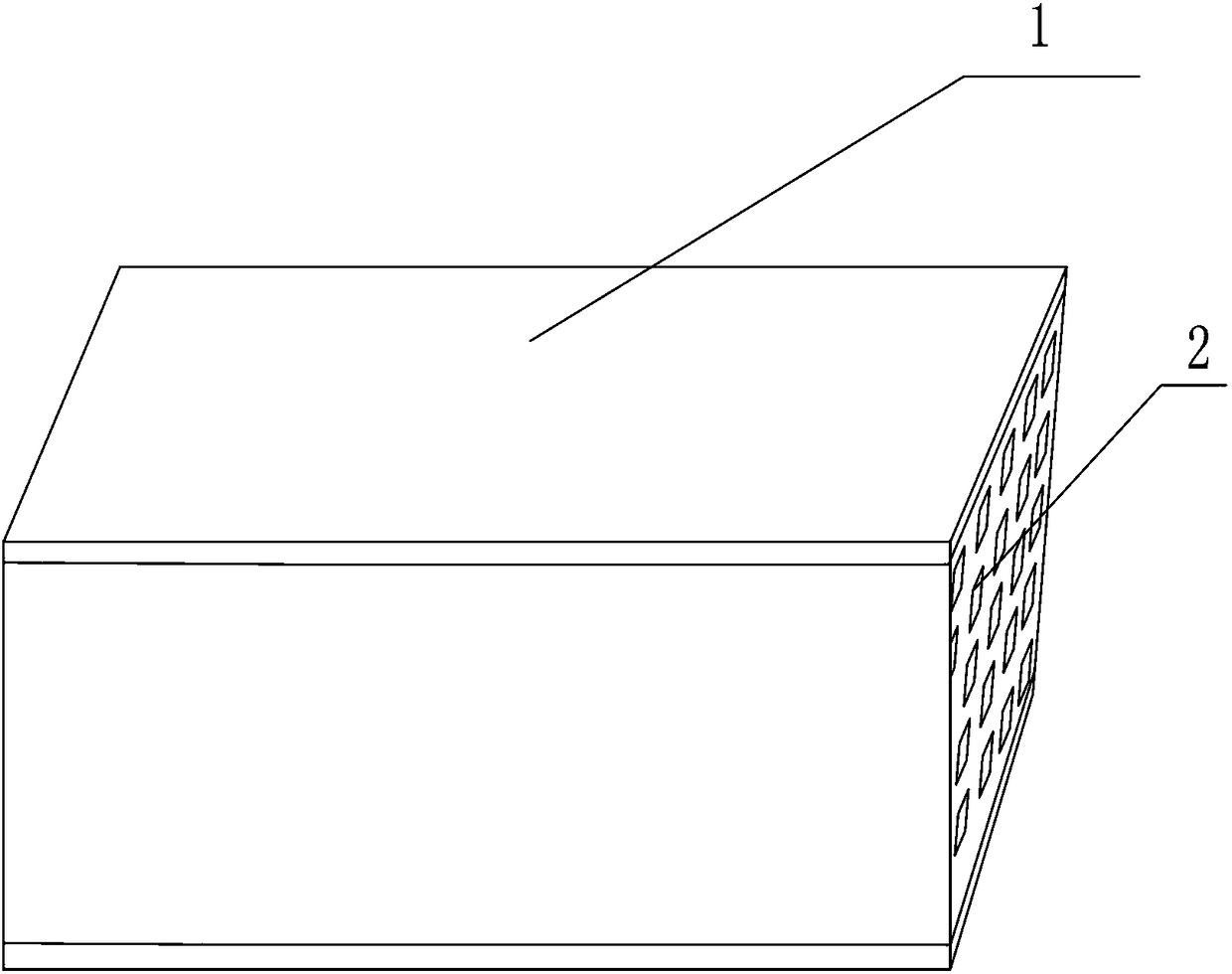

[0016] Such as Figures 1 to 2 As shown in the above, a nozzle for high-viscosity ink described in this solution, the nozzle 1 is provided with more than one nozzle unit 2, and the nozzle unit 2 includes a housing 3 and a nozzle located in the housing Shrapnel 4, the outer wall of the housing 3 is provided with a magnetic layer 5 for absorbing the shrapnel, and both sides of the shrapnel 4 are equidistantly provided with bumps 40, and the bumps 40 on both sides of the shrapnel 4 are under the action of the magnetic layer 5 They are respectively magnetically bonded to the inner wall of the housing 3, and the elastic sheet 4 is deformed into a wave shape after the bump 40 is magn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap