An active suspension using an air spring assembly

An air spring, active suspension technology, applied in elastic suspension, suspension, vehicle spring, etc., can solve the problem of amplifying the ideal control force of the suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

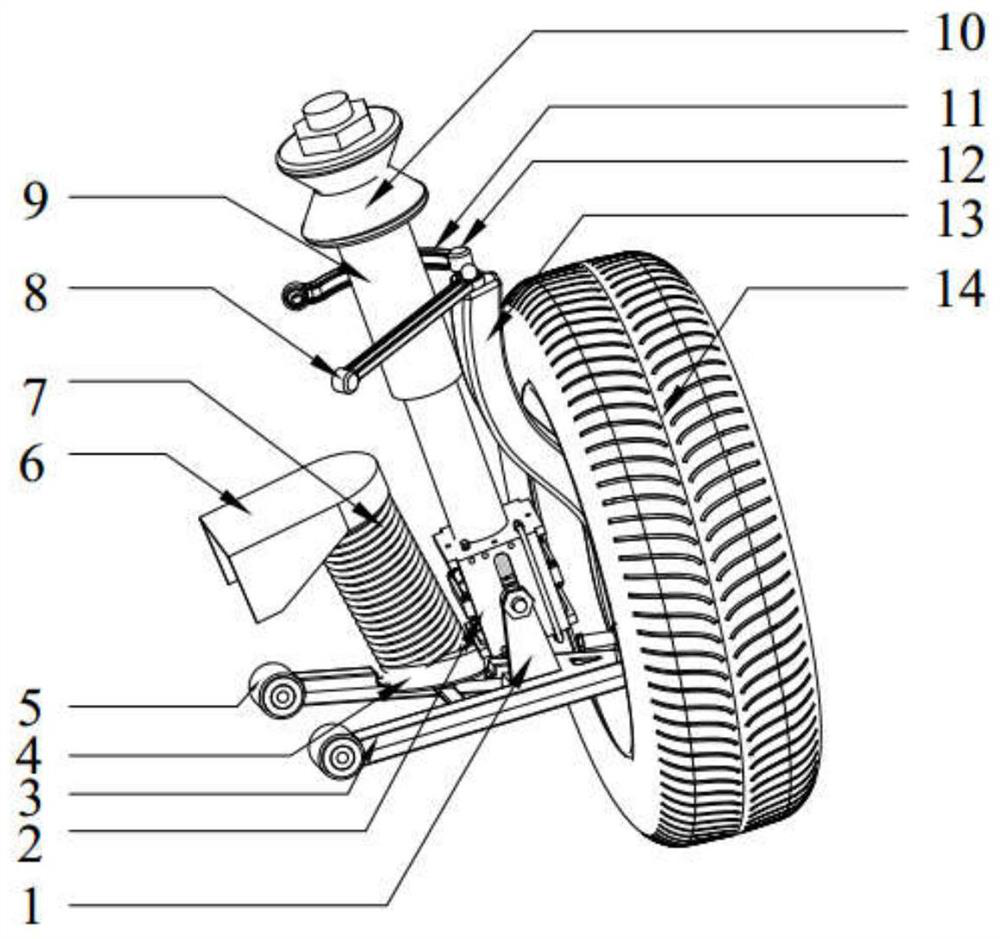

[0020] Such as figure 1 As shown, the orientation of the present invention is stipulated as follows: take the ground as "down", take the coupling assembly 10 as "up"; 14 is "outside", with bushing 5 as "inside".

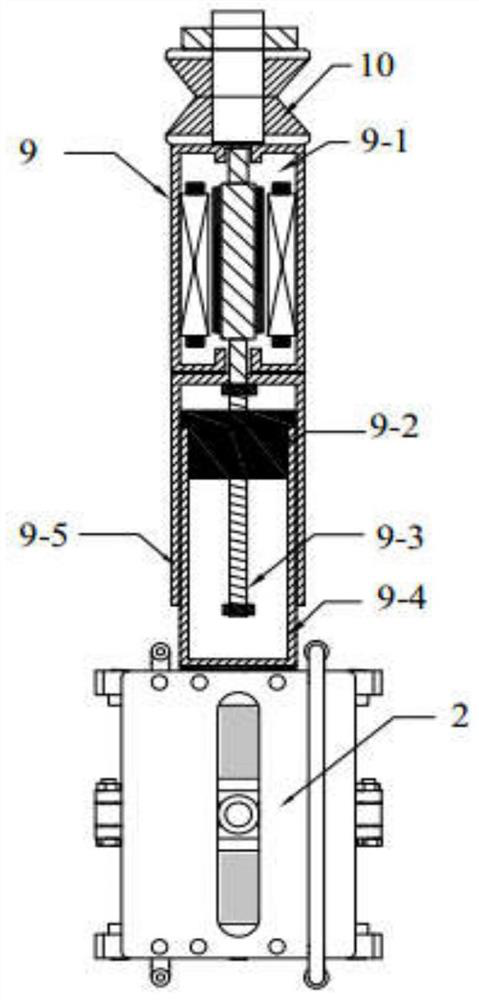

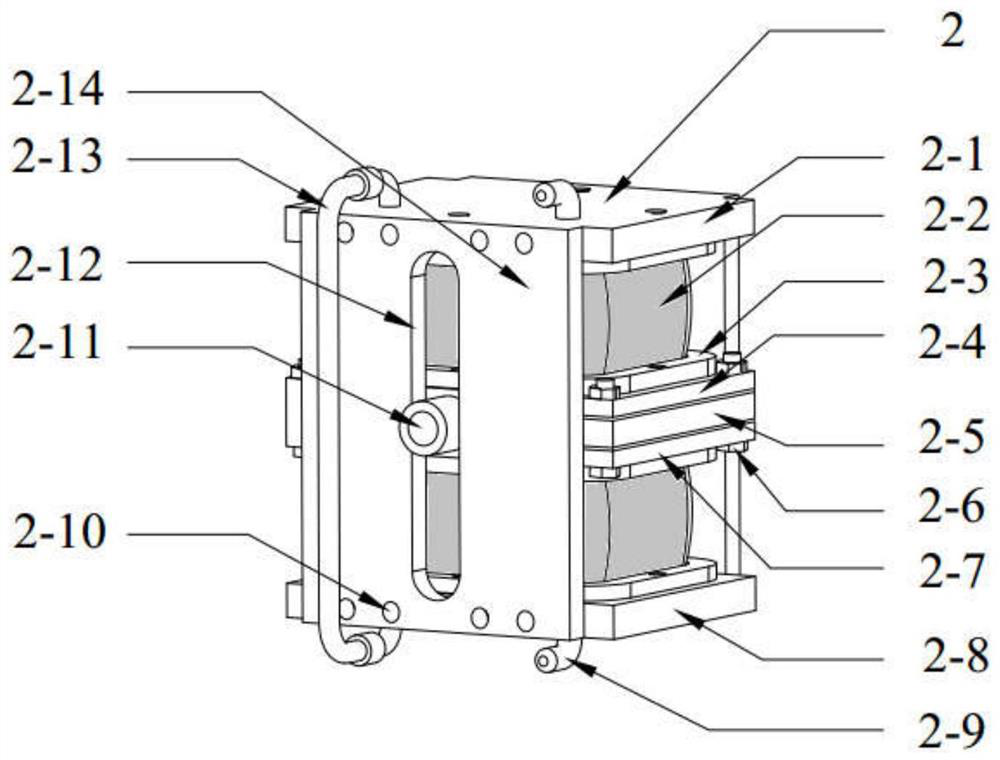

[0021] The present invention has a main force actuator 9, and the main force actuator 9 is installed between the vehicle body and the wheel 13, and the vehicle body is on the inner side of the wheel 13. The upper end of the active force actuator 9 is fixedly connected to the coupling assembly 10, and the coupling assembly 10 is fixedly connected to the vehicle body.

[0022] A helical spring 7 is installed on the side of the active force actuator 9, and the helical spring 7 and the active force actuator 9 are installed at different axes. The lower end of the coil spring 7 is supported on the spring mounting seat 4, the upper end of the coil spring 7 is fixedly connected to the connecting plate 6, and the connecting plate 6 is fixedly connected to the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com