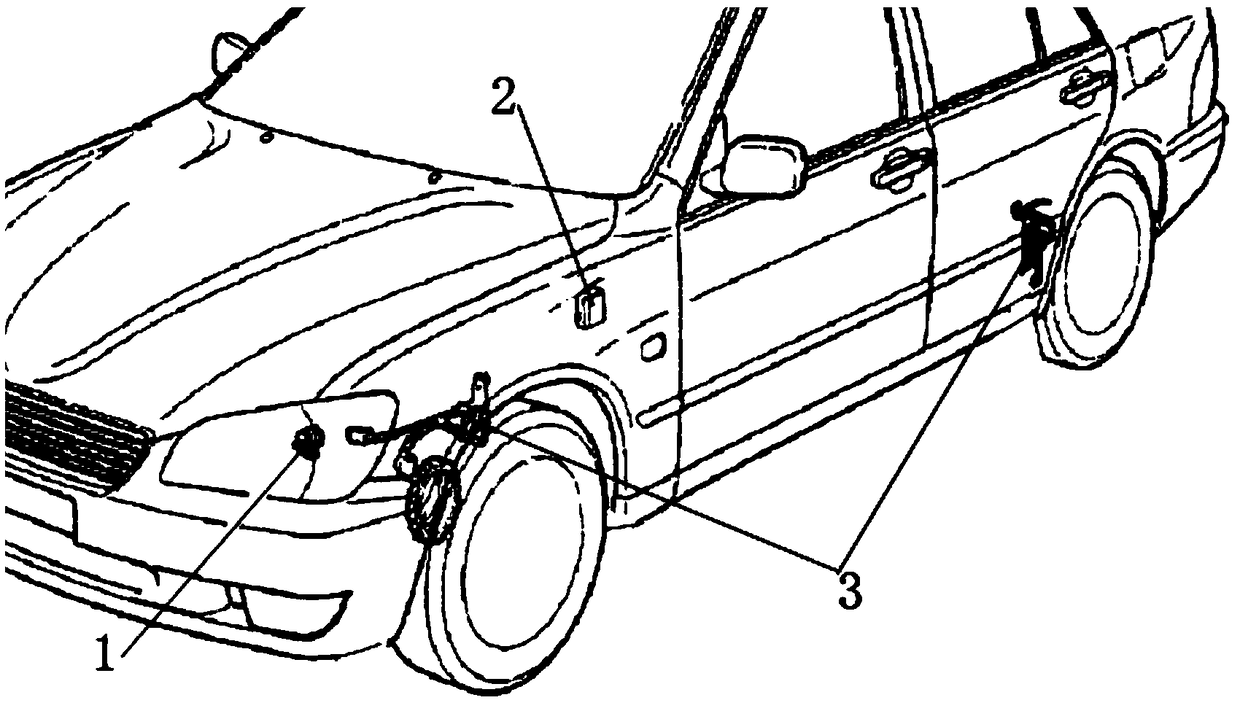

Automobile lamplight automatic adjusting method and system

An automatic adjustment and lighting technology, applied in the direction of headlights, optical signals, vehicle parts, etc., can solve the problems of increasing the whole vehicle process, high cost, and inconvenient after-sales maintenance, so as to save installation brackets, reduce processes, and help reduce heavy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, and not to limit the present invention.

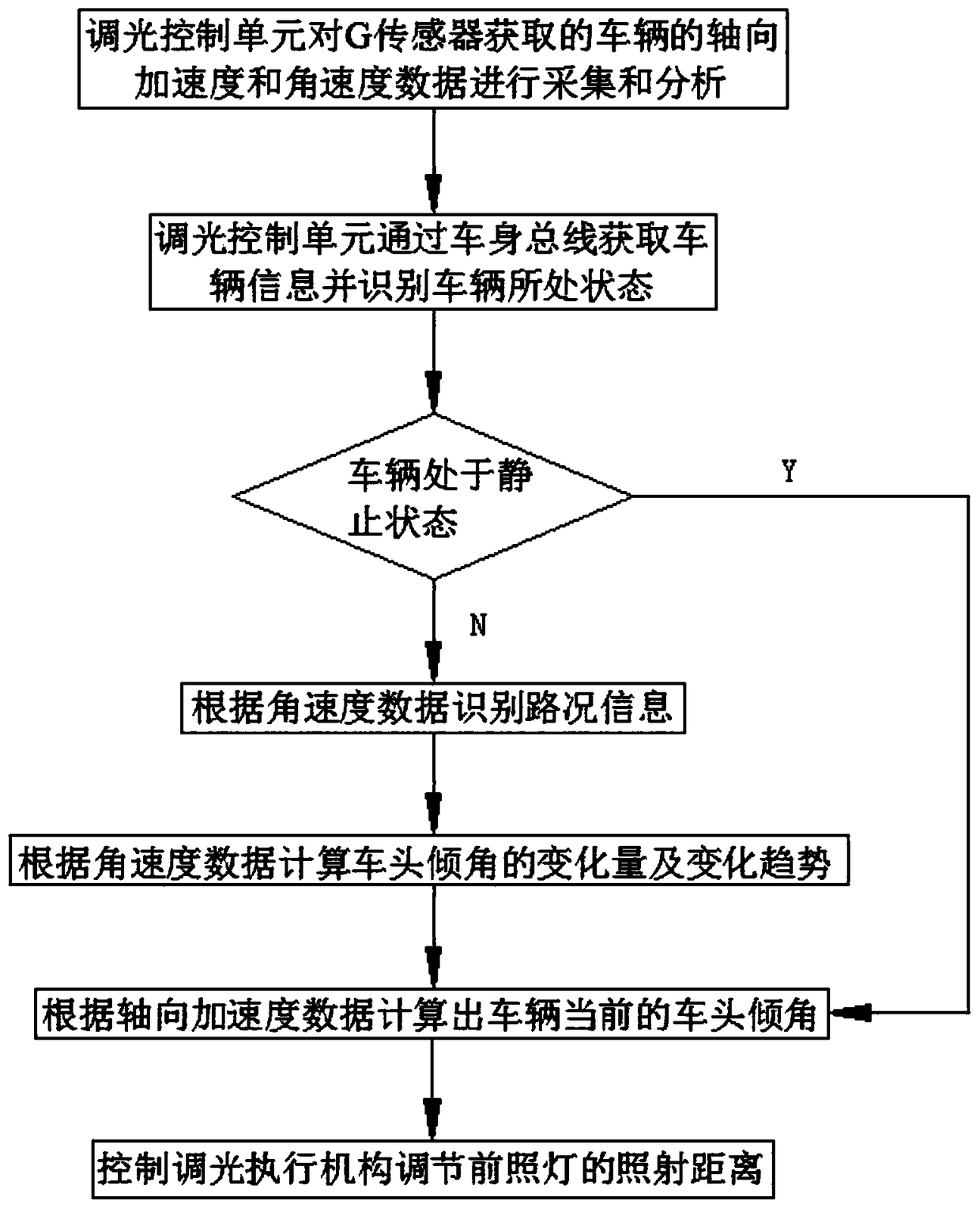

[0030] Such as figure 2 As shown, the present invention provides a method for automatically adjusting car lights, including the following steps:

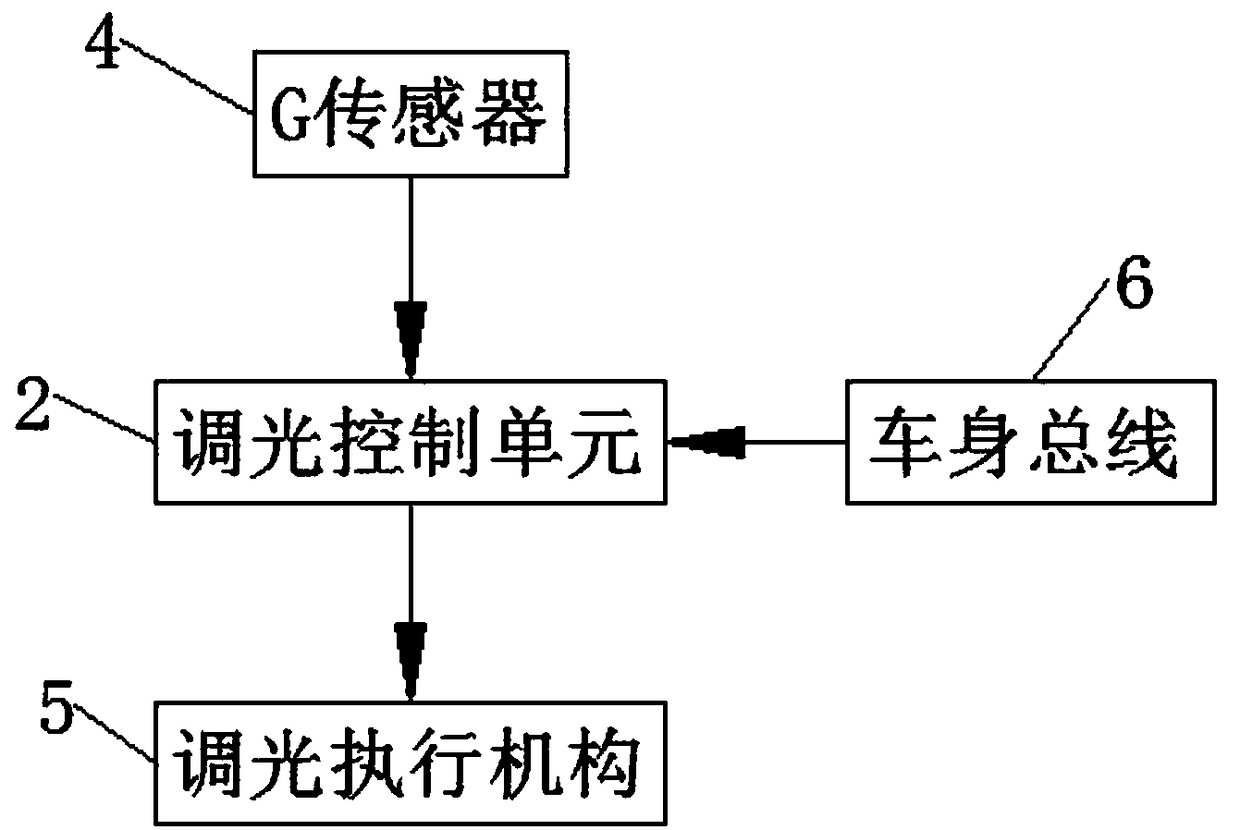

[0031] (1) A G sensor is installed inside the dimming control unit, and the dimming control unit collects and analyzes the axial acceleration and angular velocity data of the vehicle obtained by the G sensor;

[0032] (2) The dimming control unit obtains vehicle information through the body bus, that is, the vehicle speed, gear, accelerator pedal position, and brake pedal position, and identifies the state of the vehicle according to the vehicle information;

[0033] (3) The dimming control unit calculates the current head angle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com