Stereoscopic warehouse automatic stocktaking device

A three-dimensional warehouse, automatic technology, applied in the field of three-dimensional warehouse, can solve the problems of low work efficiency, inaccurate inventory, large-scale storage area, etc., to improve the accuracy and achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

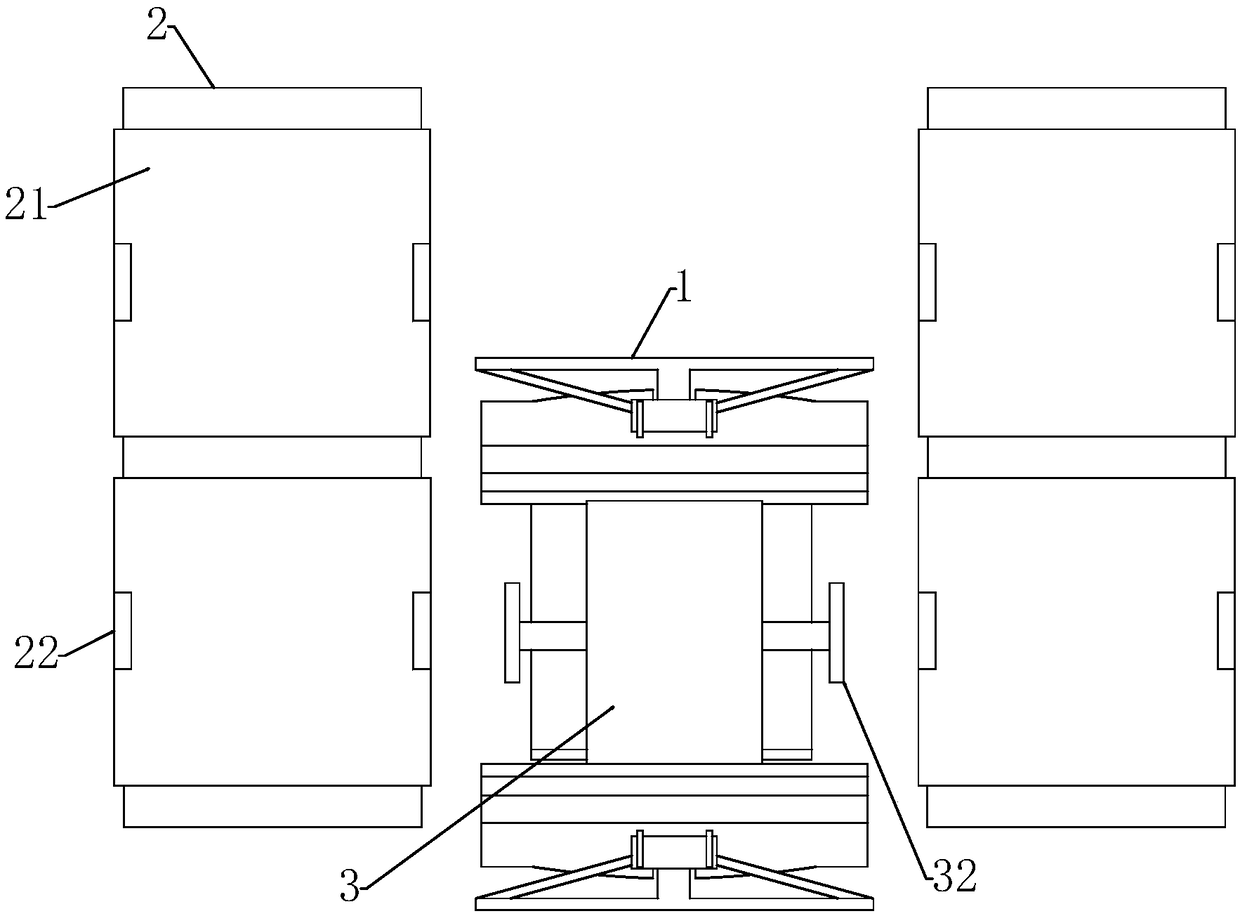

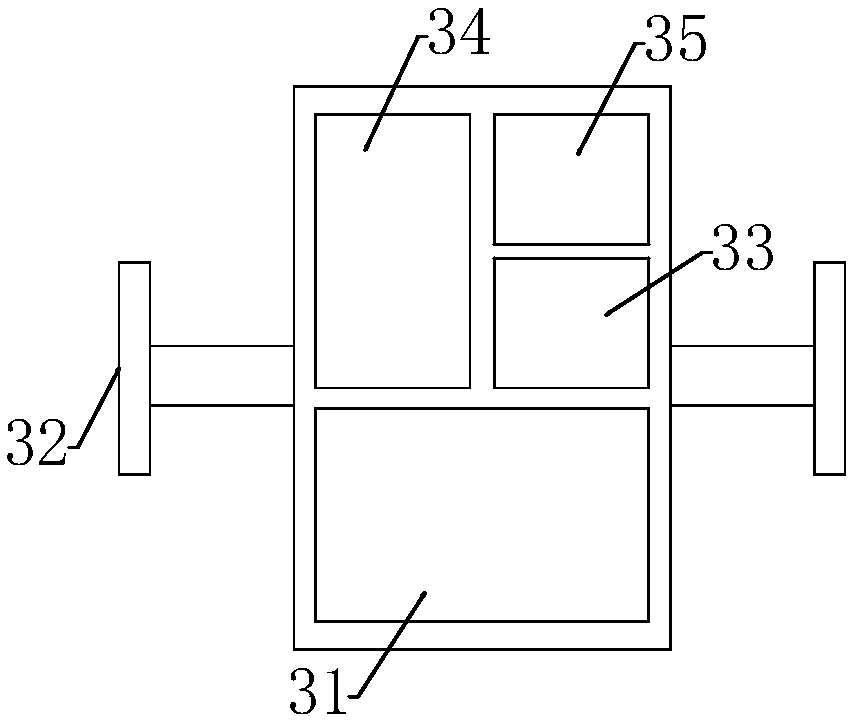

[0016] Such as Figure 1 to Figure 2 As shown, a three-dimensional warehouse automatic inventory device includes a stacker 1, a warehouse management server and a shelf 2, and the stacker 1 is connected to the warehouse management server for signals. As an improvement of the present invention, the side wall of the stacker 1 is detachable An inventory device 3 is connected, and the inventory device 3 includes a fixed RFID reader-writer 31, an RFID antenna 32, a wireless AP33 and a power supply 34. The fixed RFID reader-writer 31 is connected to the warehouse management server through a wireless AP33 signal, and the shelf 2 is equipped with The tray 21 is symmetrically provided with tray labels 22 on both sides of the tray 21 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com