Method of dynamic and variable parameter well-killing technology

A process method and variable parameter technology, applied in drilling equipment and methods, drilling equipment, earthwork drilling, etc., can solve the problems of inability to meet the requirements of safe killing of deep and ultra-deep wells, high risk of loss of control, and high formation pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Below in conjunction with accompanying drawing, the present invention is described in further detail:

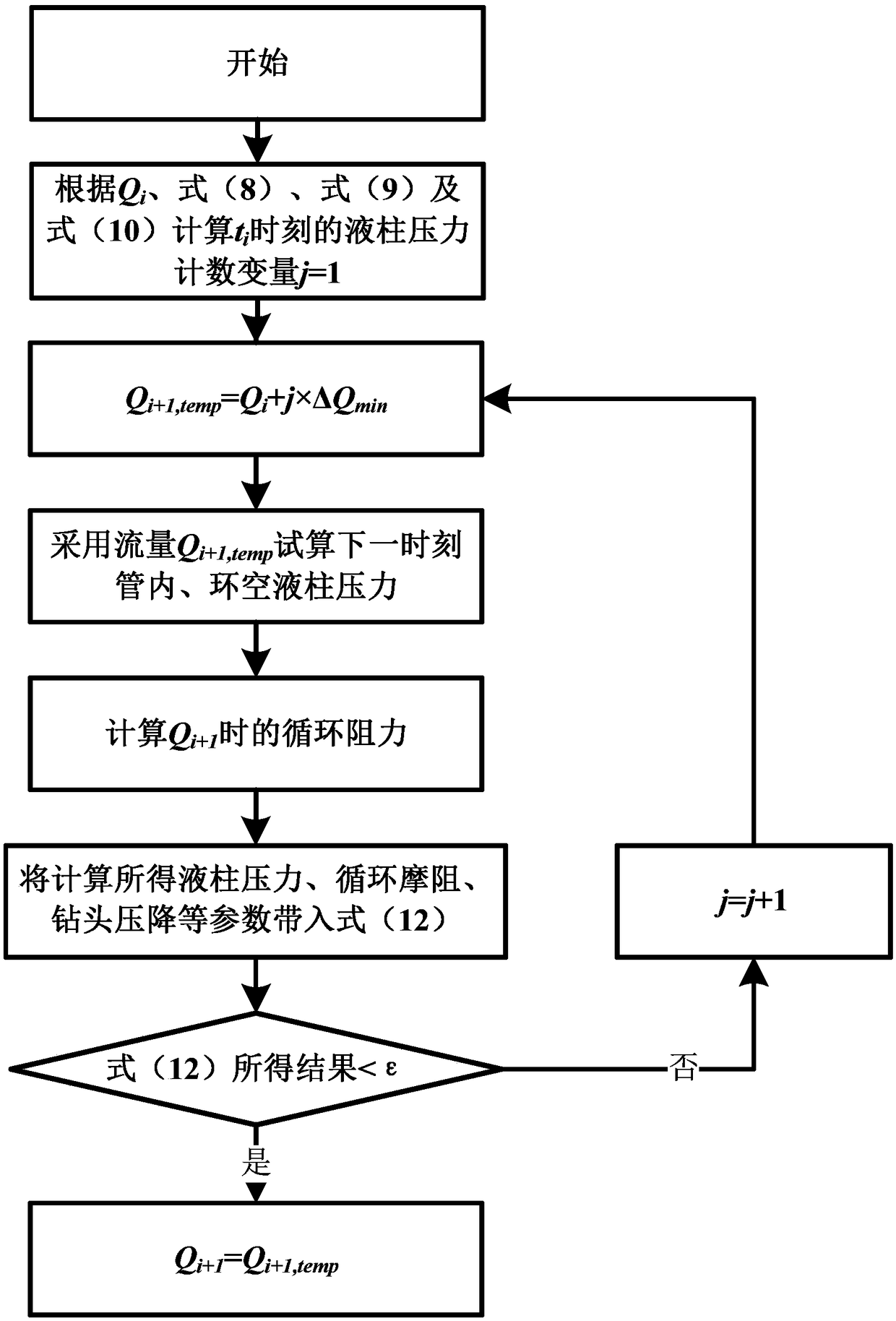

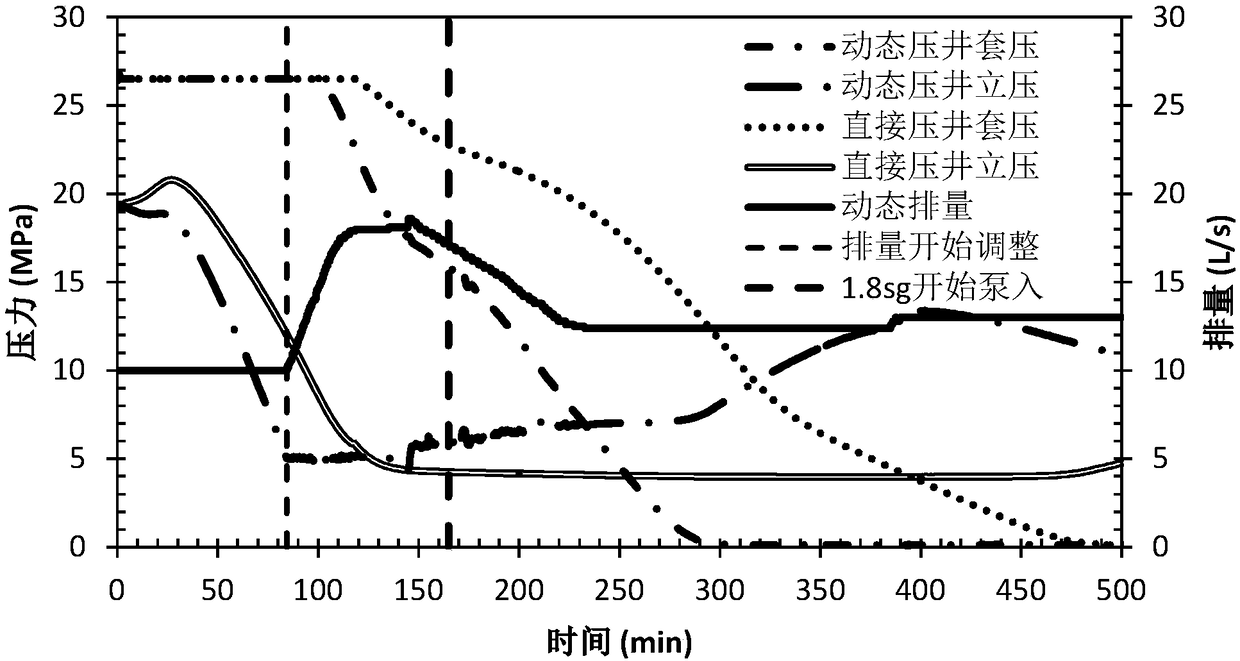

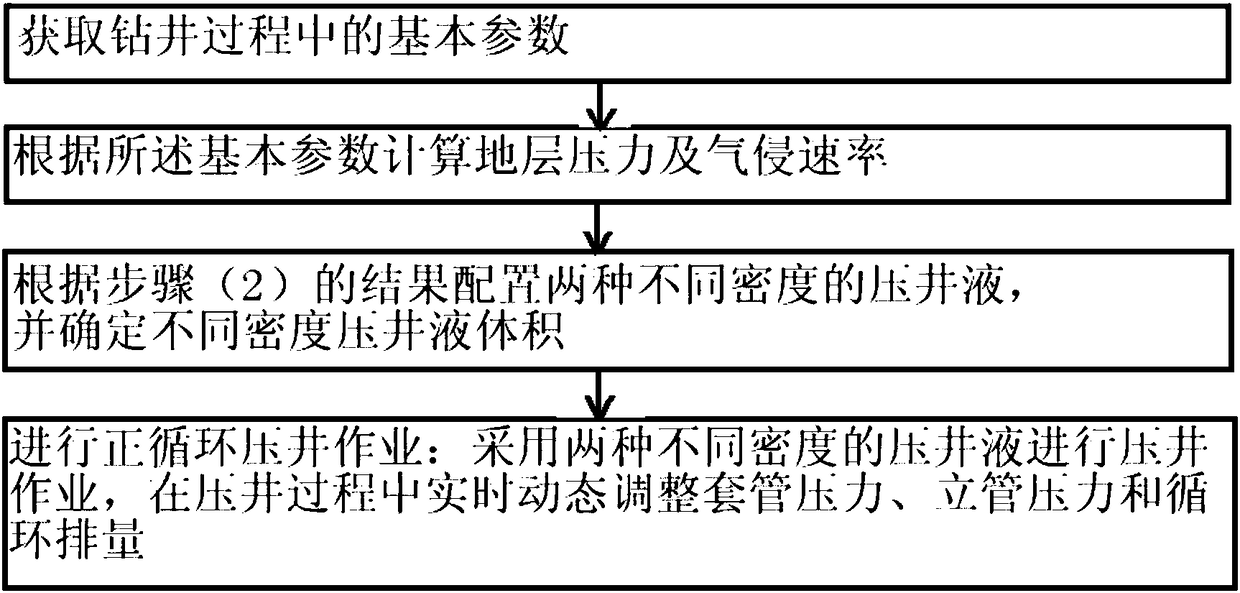

[0074] The invention proposes a dynamic parameter-variable well killing process method, which can meet the technical requirements for safe construction of deep and ultra-deep wells with gas invasion and well killing. The dynamic variable parameter killing method first determines the formation pressure coefficient according to the shut-in casing pressure, designs two kinds of density killing fluid, and determines the volume of killing fluid with different densities, and continuously pumps the killing fluid in stages to carry out the well killing operation. During the well process, the well killing displacement is adjusted in real time according to the changes of wellhead vertical pressure and casing pressure, so as to stabilize the formation as soon as possible. The implementation method is as follows: (1) first obtain the basic data of drilling and gas invasion, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com